The textile industry, as we all know, is a manufacturing industry that deals with a set of operations required for the production of fabric materials and dresses. Textile industry can generally be categorized into two types. The first one deals with the purchase of fiber from other vendors and conversion of the fiber into fabric and then working on it to produce clothes. In the second type of textile industry, the investors usually buy fabric from the vendors and then start cutting and sewing of this fabric to manufacture textile.

Why is the Textile Industry an Important segment of the Manufacturing Industry?

The manufacturing industry is one of the four major types of industries existing in the world. AS all products that we use in our daily life are manufactured by one or the other means we can understand the importance of the manufacturing industry. From clothing materials to the food business, from the medicines we consume to the vehicles we use, everything comes from the manufacturing industry.

The textile industry is a type of manufacturing industry. It involves different types of manufacturing processes and produces the end products. The textile industry, as we mentioned earlier, mainly deals with different types of manufacturing activities including yarning, weaving, coloring, cutting, sewing, and stitching. That means a single manufacturing industry is likely to have many work centers.

Importance of ERP for Textile Industry

Involving multi-staged processes, multiple work centers, and the multiple number of warehouses, the textile industry needs proper coordination of all these activities and units. The organization of all these processes is a very difficult and time-consuming effort. Enterprise resource planning software that has the capability to deal with different operations in the industry is best suited to help you. ERP solutions can coordinate different operations such as warehouse management, stock management, work center coordination, work hour management, employee management, purchase and sale management, bill of material management, and every other aspect.

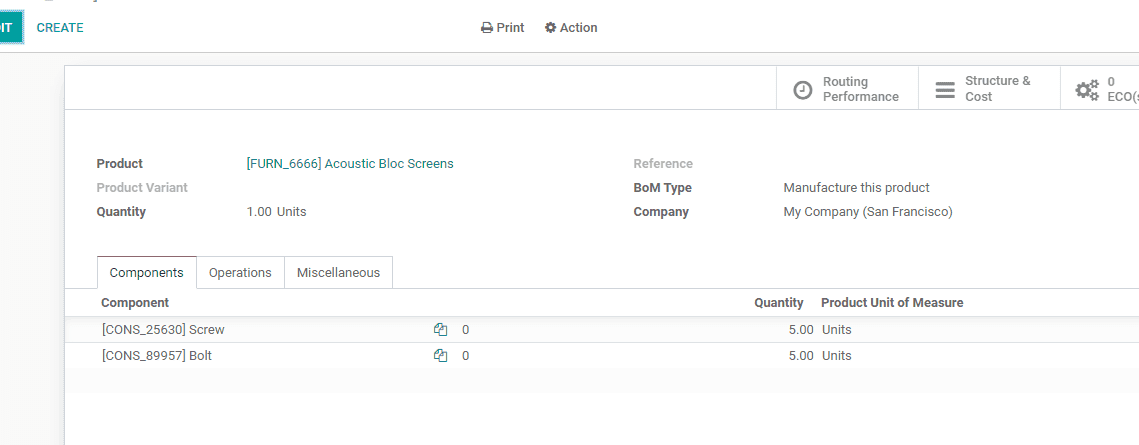

What is the bill of Material and How Important is it?

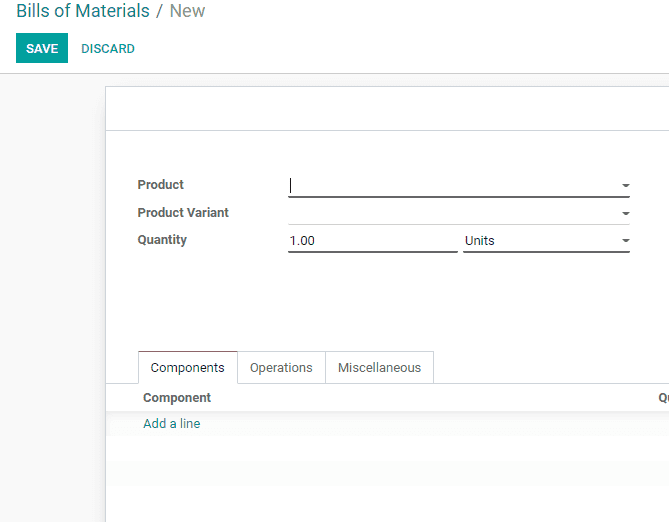

It is the list of components used for manufacturing a product. It is very helpful in any manufacturing industry as the price of a finished product is decided mostly based on the price of the components and the labor cost. A bill of material will help the investor to calculate the exact price of all components used for the manufacturing process. Besides, it helps to calculate the expected time required for completing a process. Such support helps the investor to assess the efficiency of a work center and hence improve the efficiency.

Odoo open-source software is one of the best solutions for manufacturing-related worries. Odoo helps a user to get the best support for coordinating the activities. Odoo has separate modules for manufacturing, purchase, sale, and other activities. The Odoo manufacturing module includes a feature called Bill of Materials. This helps the industry to improve performance and work efficiently. This also helps the industry work in a more systematic way.

In this blog, let us take a look at how the Odoo Bill of Material helps the textile industry. Odoo’s bill of material helps the user in different ways. The key benefits are listed below.

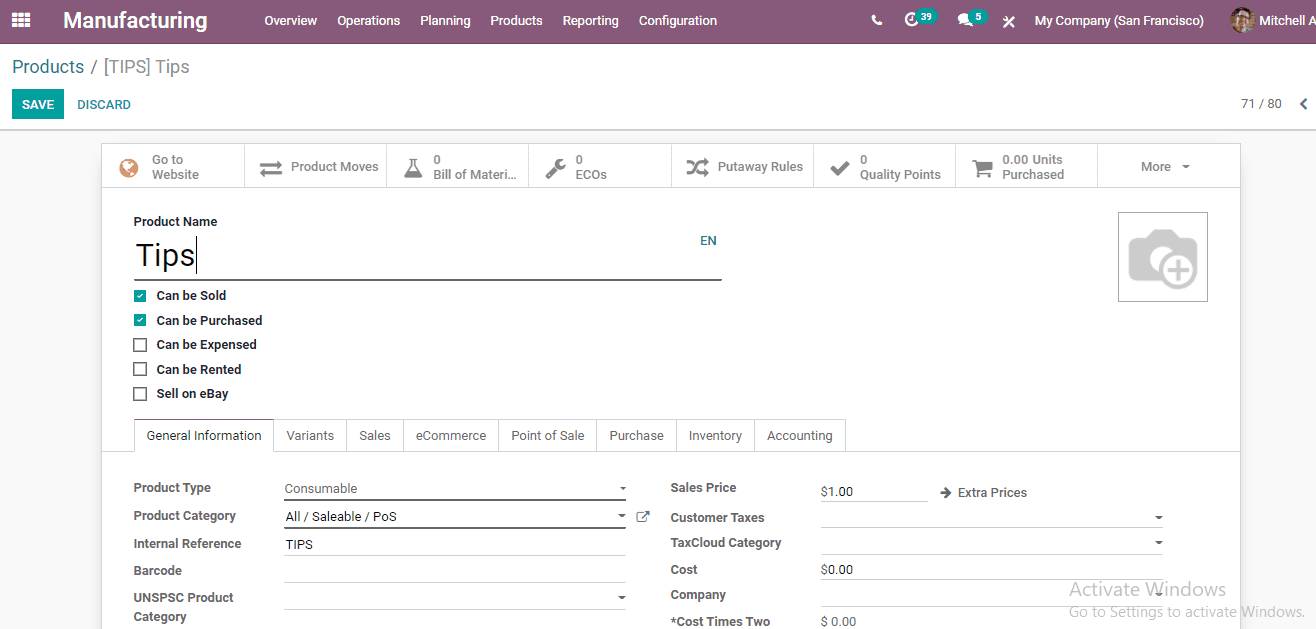

Manage Components for Different Products in the Industry

Odoo Bill of Material is a feature included in the Odoo Manufacturing Module. This feature helps the users to manage all the products being manufactured in the industry. For example, in the textile industry, the products can be of different types. The industry could produce bed sheets, curtains, shirts, and other clothing. The Odoo BOM helps the investors to select the components for the product after seeing the product. This helps the business to ensure a full-fledged bill of material management for each product. Bill of Material can also help to calculate the time required for the production of each product.

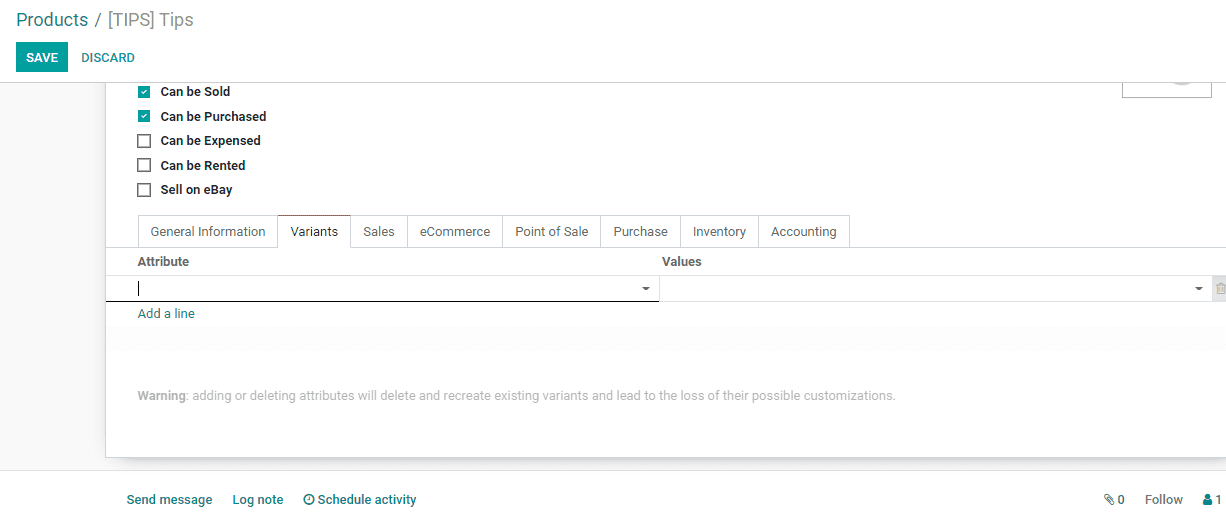

Manage Variants of Textiles Products

Odoo 14 helps to create a separate bill of material for all product variants. Suppose an industry is manufacturing multi-color shirts, then the BoM feature will help to create separate BoM for all these products. The attributes including size, color, and other components can be calculated and included in the BOM. Odoo, hence, helps the industry to calculate the exact price for all product variants.

Efficiently Manage the Number of Units Produced

A BoM which is generated based on order helps the investors to calculate and mark the number of units produced with the same BoM. This helps to prepare the batch and issue a lot or a serial number.

The quantity management also helps to calculate the availability of raw materials required for manufacturing the products in the textile industry.

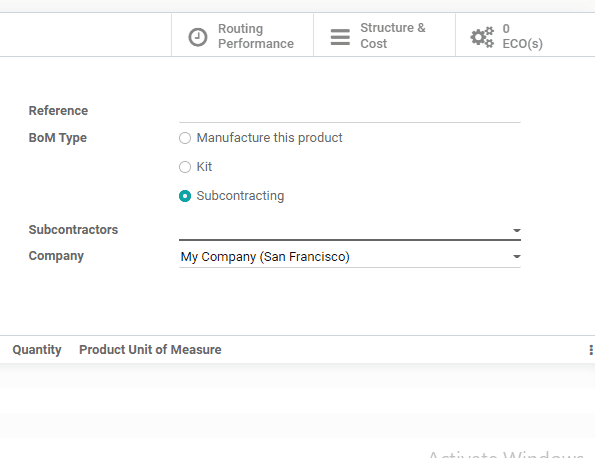

Manage Subcontracting of Semi-finished Textiles

Sub-contracting is a major part of all manufacturing industries. Subcontracting means the industry can depend on sub-contractors for getting semi-finished products. This can be done either by considering the raw materials required for the sub-contracted product or without referring to the product. Odoo BOM helps the users to subcontract the manufacturing of material for shirts, T-Shirts, or other materials. In short, a textile industry can outsource the yarn or weaving work to a sub-contractor.

This will help the industry to reduce the number of work centers and employees. Sub-contracting can be done from the BoM stage.

For more information: https://home.mycbms.com/subcontracting-in-odoo-14-manufacturing

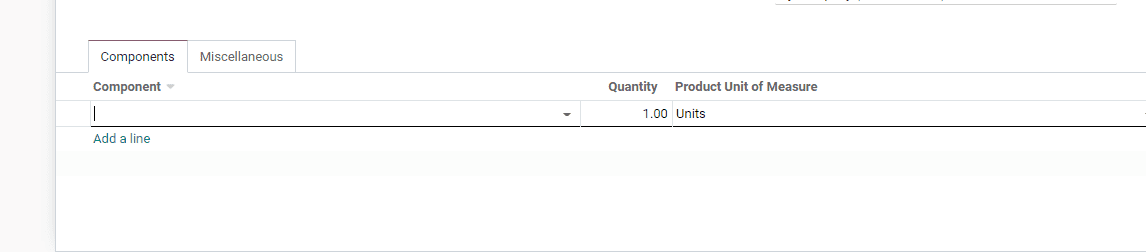

Manage Fiber, Yarn, and other Components Easily

Component management is the key task of BOM. In the textile industry, there are a number of components including year, fiber, semi-finished materials, color, chemicals and other substances. A BOM can easily manage all these components in an easy way.

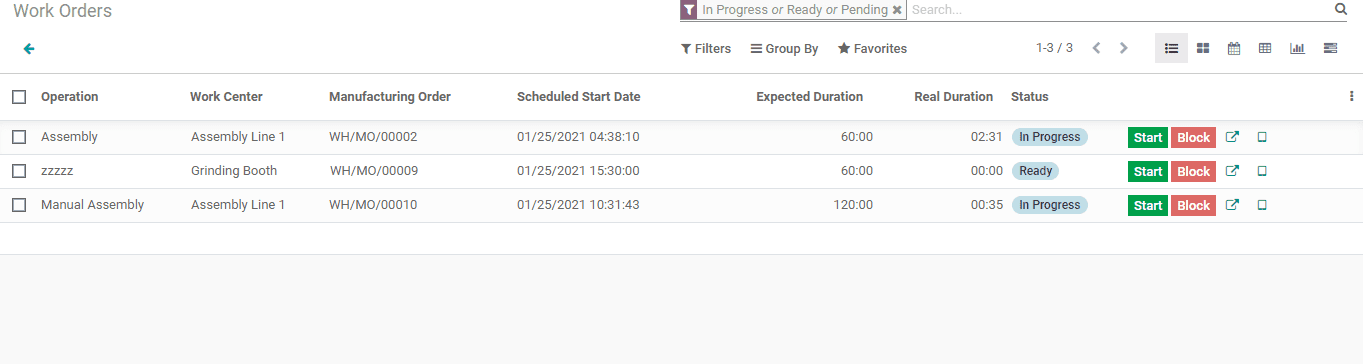

Manage Operations

In the textile industry, there are a series of operations before completing the production of a textile product. The operations may include yarning, weaving, cutting, sewing, coloring, and packing.

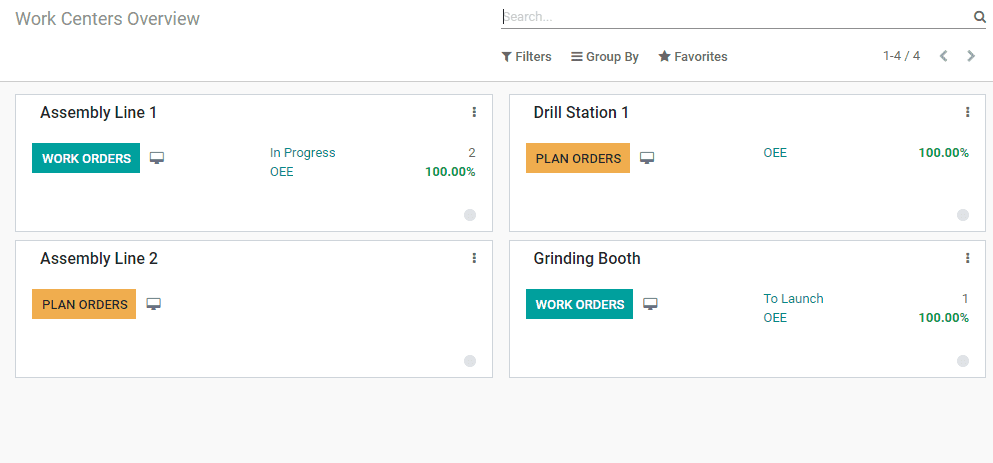

Coordinate Work Centers

With many work centers, the textile industry can work efficiently only with proper coordination. In Odoo 14 manufacturing, work center scheduling can be modified in the BoM stage. The product management and the work center operations can be controlled and the expected time for completing the task can be calculated with the help of this feature.

You can know more about Odoo work center support by reading Work Center in Odoo 14

Manage Byproducts

In the textile industry, there would be large quantities of cloth materials that cannot be used for producing the main products. The waste generated while cutting cloth material for the stitching process can be used for different purposes including manufacturing mats, table covers, handkerchiefs, and other products. Bill of the material enables the user to manage all these byproducts in an effective way.

Manage Routing

In Odoo 14, Routing is part of the BoM. Here, routing means the involvement of different work centers for the completion of finished products. With BoM, where all activities for different work centers are listed routing can be completed.

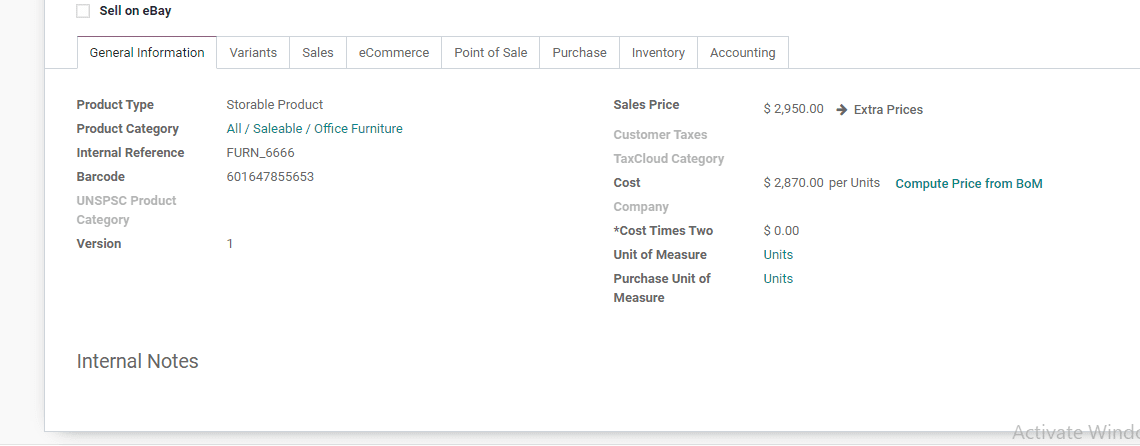

Calculate price accurately

With accurate details about the raw materials used for production and accurate information on the number of raw materials, the industry can easily calculate the total expense for producing a product. Besides, the effectiveness of the work center and other aspects can also be analyzed from here. This helps the manufacturer to calculate price easily.

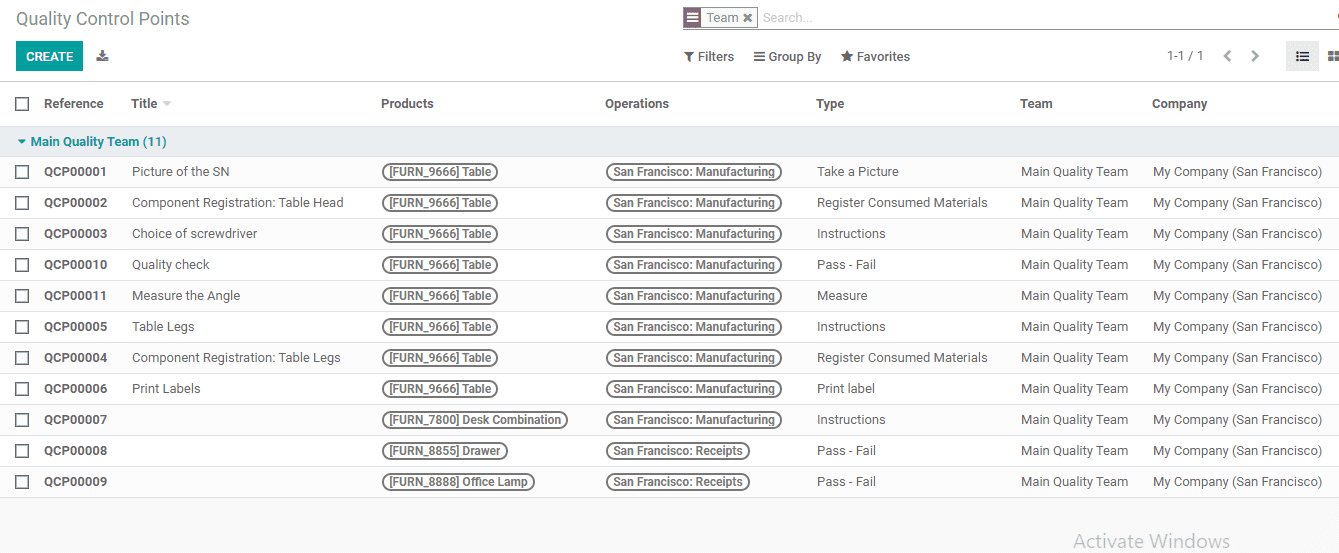

Quality control

Odoo has a module to manage the quality of the products. In the textile industry, Odoo can entrust different quality teams to check the quality of the fiber, coloring, or other activities. The quality of the finished product, as well as packing, can be managed and monitored. This will help to categorize the product to export quality and other grades. This will benefit the business.

Go through Ensure Quality of Products with Odoo Support for more details.