The metal industry is venturing into a new phase with a resurgent economy in many countries. The rising demand for metal products for manufacturing different products is also a positive sign. With the increased demand for machine parts and other instruments using steel, many industrial units and small businesses have also started emerging globally. Small business units engage in the production of metal-based equipment storage, machinery for the manufacturing industry, welding different products, and manufacturing different products, and by-products. The durability of the metal products and cost-effective availability ensure support for the metal industry.

ERP support

With stiff competition in every field, business requires a comprehensive support mechanism for ensuring growth. Enterprise Resource Planning Software can be of great help to the users as the ERP will surely help the business to grow steadily. The ERP helps the business to organize all activities including the purchase of materials to the sale of finished products.

Like every other manufacturing industry, different stages are involved in the metal industry also. The ERP will help the investor to coordinate the operations of all these departments and assure better results. Odoo 14 offers a wide range of features in the Manufacturing Module. This is sure to help the business reap the best result. In this blog let us take a look at how Odoo can help the metal industry.

Easy to Manage Industrial Products

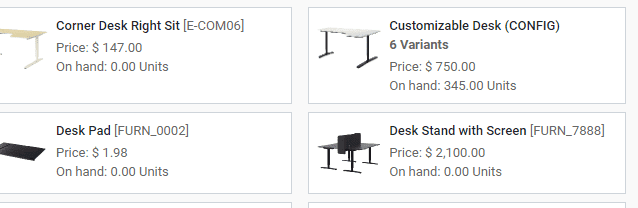

The user can easily create new products using the Odoo module and enter product details. The management of the product can be done with a few clicks. Every detail of the product can be entered including the product price, unit price lot number, etc.

Odoo manufacturing helps the user to prepare a product list with the support of ERP solutions. For a small metal industry, the user can create different products including chairs, tables, metallic roofing materials, and other industrial products using the product creation feature of Odoo. The user can easily categorize the products and name the products. Product updating and editing can also be done.

The user can add product type, category, barcode, and other details while creating the product. The sale price of the product per one unit and the extra prices can also be added in the form. This will help the user to get an idea about the price and product.

The user will also be able to manage product variants. Variations in a metal industry could have price differences and this can also be attributed easily.

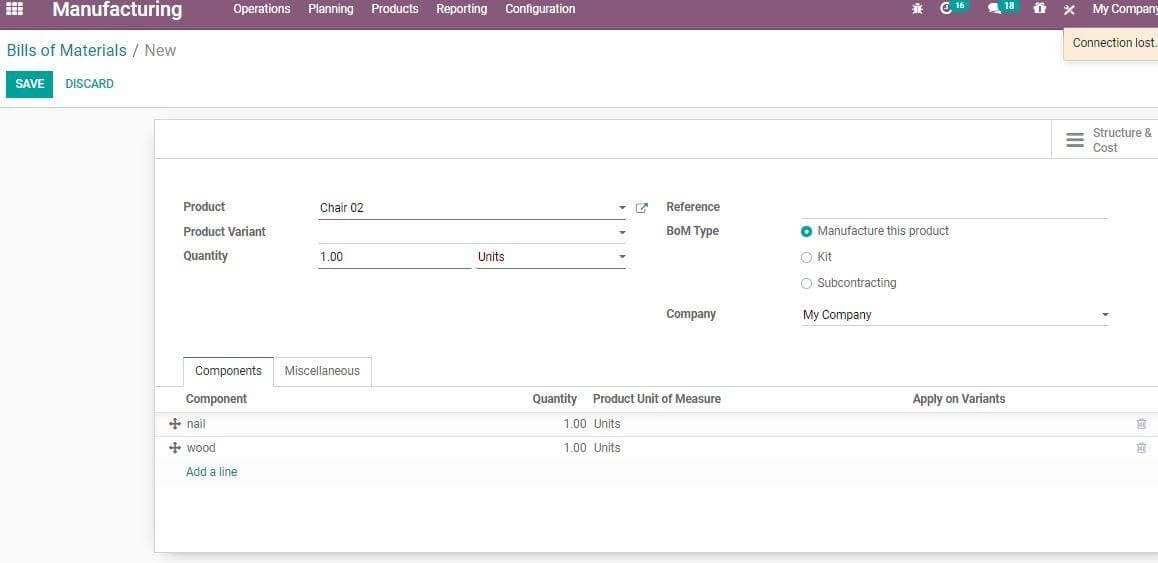

Bill of Material

This feature helps the user to accurate details about the product, LdM Type, company, and reference details. A user can create a bill of material in a few steps. Using the BoM create form a metal industry users can add product details, variant details, and the quantity. The raw materials or components used for production can be added under the component tab. The user can add any number of lines under the component tab. The name of the component, minimum quantity, consumed in production, and other details.

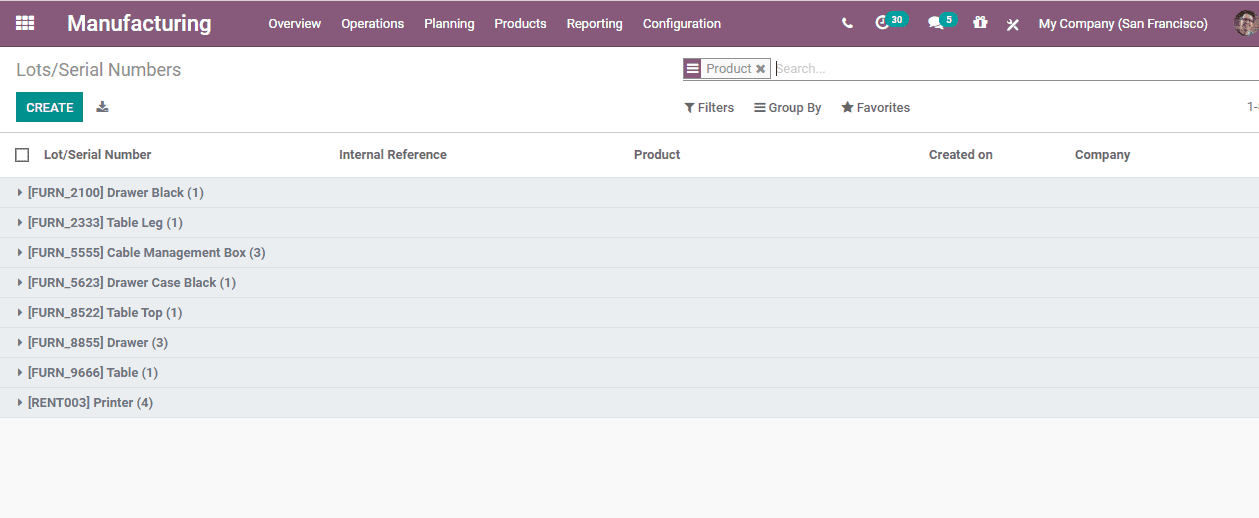

Lot and Serial Number

The lot and serial number for manufactured products help the industry to operate in a professional way. The user can access a lot or serial number details along with the product name and the date of manufacturing.

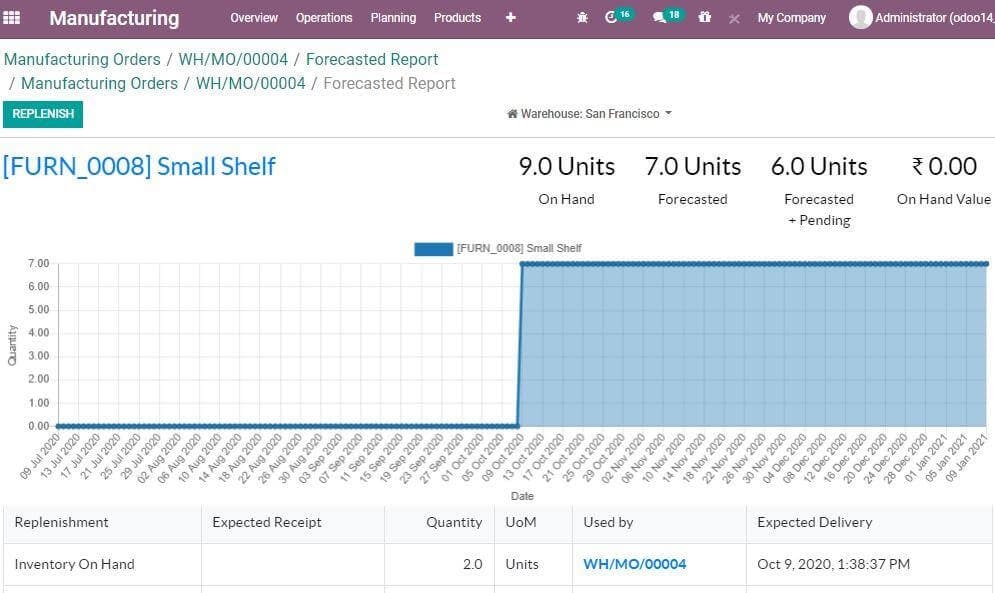

Plan Production

ODoo helps to organize manufacturing orders and work orders. This helps the user to plan the manufacturing process based on the deadline for supplying or delivering the product. The production speed and capacity can also be adjusted based on the requirement.

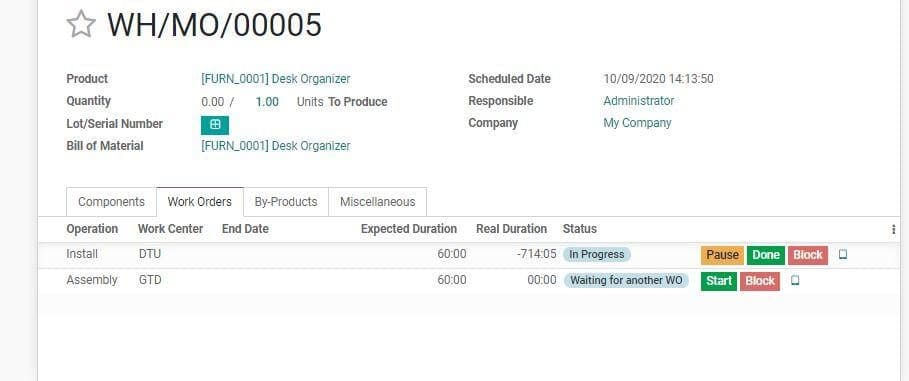

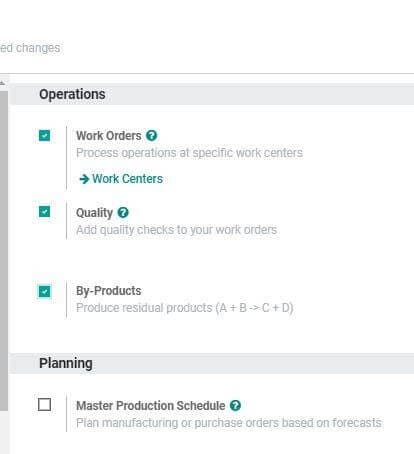

Plan the User of Work Centre

The metal industry will need the support of more than one work center for completing the production task. This can be managed at the bill of the material stage. Here, work centers can be set for each operation. If the industry requires welding, assembling, and painting units, Odoo can easily help you to set up three different work centers. The wok center management also helps the user to set the estimated time for completing each process. The actual time taken at each work center will also be recorded. This will help the calculation of effectiveness.

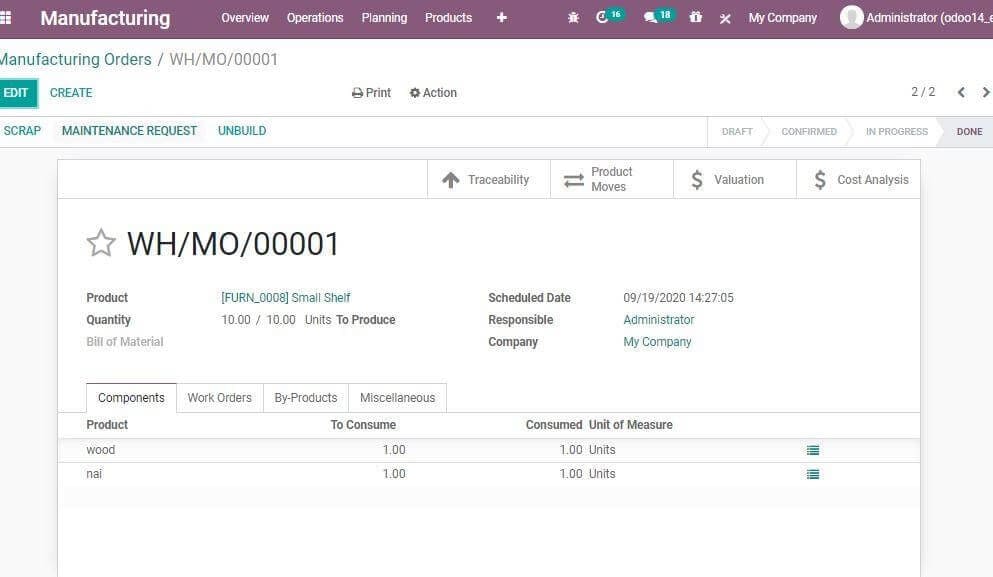

Manufacturing Order Management

Manufacturing order management is the prime feature of the Odoo Manufacturing module. A user will be able to get a glance of all manufacturing orders from the dashboard. The number of products to be manufactured and the type of product can be understood here. The delivery date of a product and the unit of measure can also be calculated. Odoo also helps a user to get an idea of the order’s

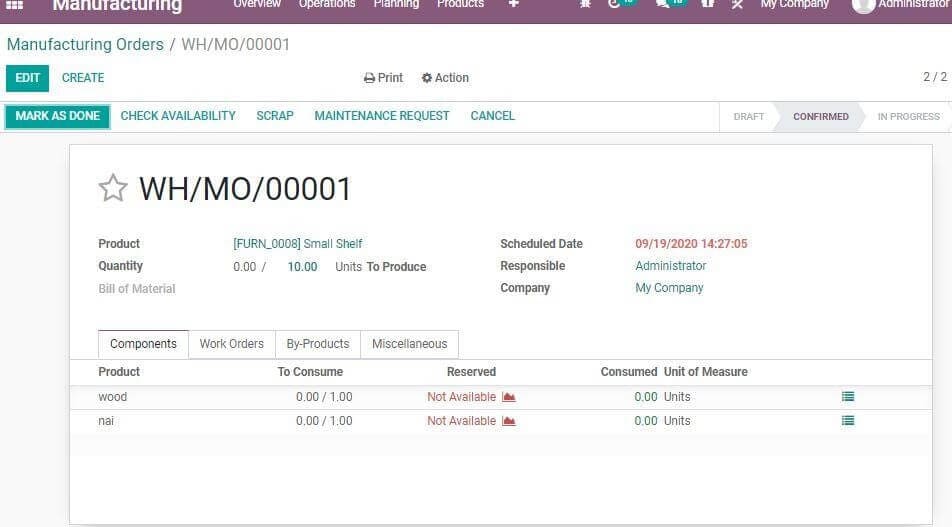

Check Availability of Raw Materials

Availability check is a feature that helps to identify the availability of raw materials for production. At the moment of creating a manufacturing order, the user will get an idea about the component availability. Availability can be checked under manufacturing orders. Here, there is a tab named Components. Under this tab, a user from the metal industry can check the availability of components like metal sheets, screws, bolts or paint. IF the product is not available then you can find the reserved status as not available

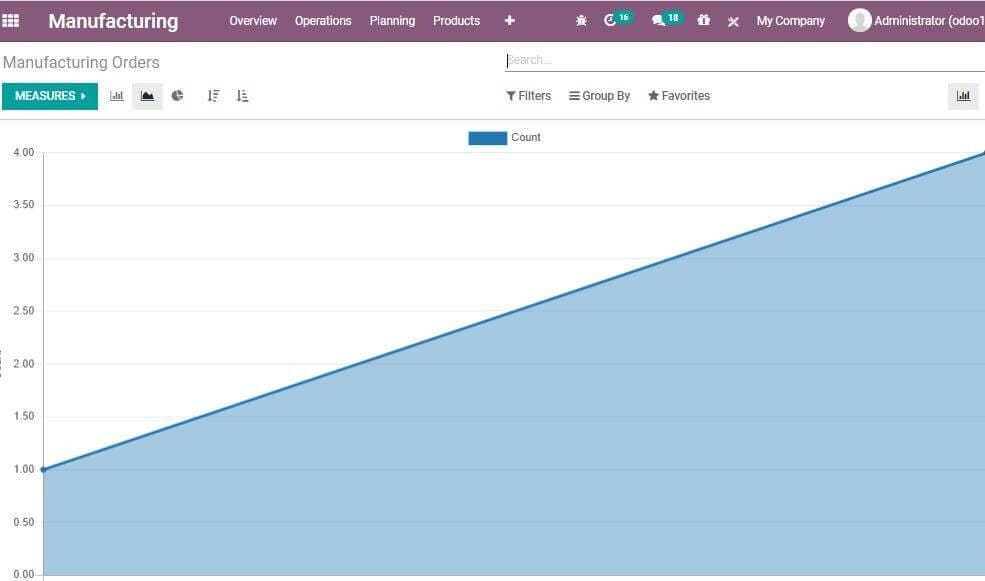

Generate Report

Odoo helps to generate reports. A well-prepared report will help the management to assess the performance of the work center. Odoo supports the generation of reports on manufacturing orders, work orders, and work center operations. Odoo reports are sure to benefit the company by improving growth.

Easy routing

The operation at different work centers can be coordinated easily. This can be done at the Bill of Material stage. Here, an industrialist can set the workstations where the works have to be completed.

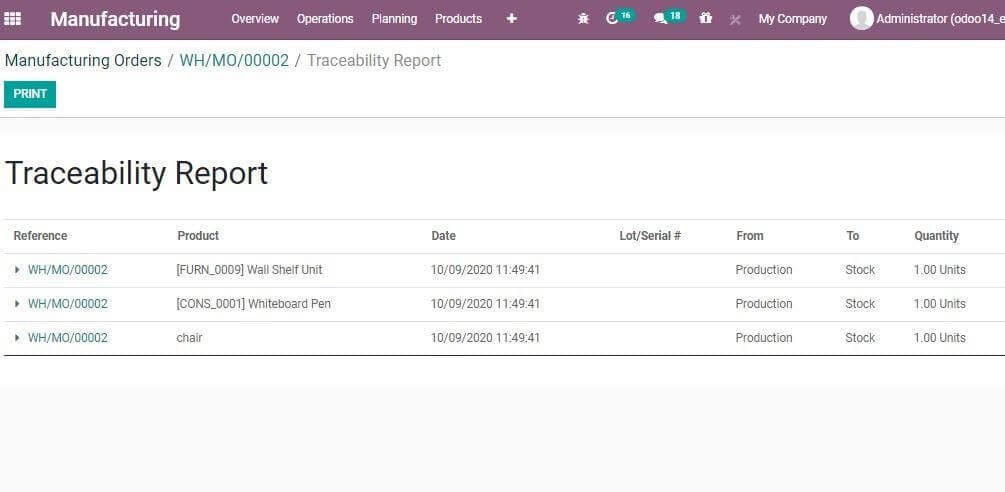

Traceability of the Manufacturing Process

Product routing helps to trace the product at different stages of work. Besides, Odoo’s support for lot and serial number management helps to track a product even after its completion. The product movement can be traced from the purchase of raw material to the delivery of the finished product with the help of Odoo.

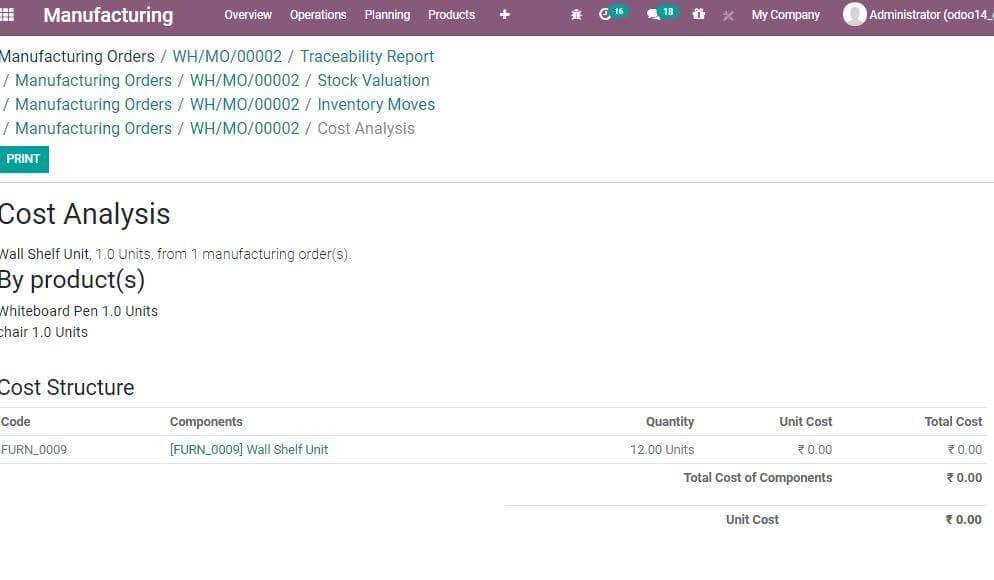

Cost Analysis

Financial management is very important for the success of any business. Odoo Cost analysis feature helps the business to analyze the cost required for producing a product and its bye products. This helps in planning the budget and pricing the product in a more effective way.

Refer to our blog to know more about the benefits of ERP for the Manufacturing Industry

Frequently Asked Questions

1. Which industries can ERP be used for?

ERPs can be used imperatively in ten major fields namely Education, Manufacturing, Food Industry, Health Care, Retail, Construction, Automotive, Government sectors, Oil And Gas, and Real Estate. As people search for ERPs that can be used with more ease and risk-free management, the Odoo ERP can be facilitated for every type of business.

2. Which ERP system is commonly used in the manufacturing industry?

An ERP system that is used in the manufacturing industry should possess different business operations and execute them systematically. In the metal industry, Inventory Management, Supply Chain, Finance, Traceability, Product quality, Automation, Order Tracking, Customer Satisfaction, etc. These business processes can be offered under a single roof with Odoo ERP modular structure.

3. Is ERP Specific to Manufacturing Industry?

There is no specific ERP in Manufacturing Industry. Depending on the size of your organization, the Odoo ERP is a wizard tool for your business. You can handle multiple planning strategies and control your business anywhere with the Odoo ERP. Within a few clicks, it can imply the manufacturing business cautiously.