Inventory is an idle stock of physical products containing an intrinsic value and kept by a company in its possession in various forms waiting to be packed, stored, converted, used or sold in the future. Every organization involving the process of manufacture or sales of products depends on the inventory.

While you are using an inventory system, you can optimize your warehouse by knowing which products are most sold, so that you can group them together for easier access. You can even divide your stock for better categorization and processing of orders.

Good warehouse implementation ensures that products move automatically to their appropriate destination. For instance, if a warehouse contains hazardous or dangerous items, it is important to ensure that those materials are stored separately to prevent contact with other products. So they must be kept in different locations in the warehouse. To make this step easier Odoo provides the technique ‘Putaway rule.’ This will avoid the mismanagement of products in the warehouse.

Usually, removal strategies are used in choosing operations to select the best products for quality control purposes or because the product is expiring. There are different removal strategies like FIFO, LIFO, etc.

Let’s discuss in detail about the removal strategies and putaway rule as well.

Putaway rule

[wpcc-iframe loading=”lazy” width=”100%” height=”315″ src=”https://www.youtube.com/embed/t7zEFGsMqNI” frameborder=”0″ allow=”accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture” allowfullscreen=””]

Putaway is the mechanism by which goods are taken off the receiving shipment and put in the most appropriate location. This will help to arrange different products in a warehouse at different locations and avoid the wrong storage of products.

By applying putaway rules on the products, we can move products from the receiving location to separate shelves or racks within the warehouse itself. The product movement will happen automatically once we assign this rule.

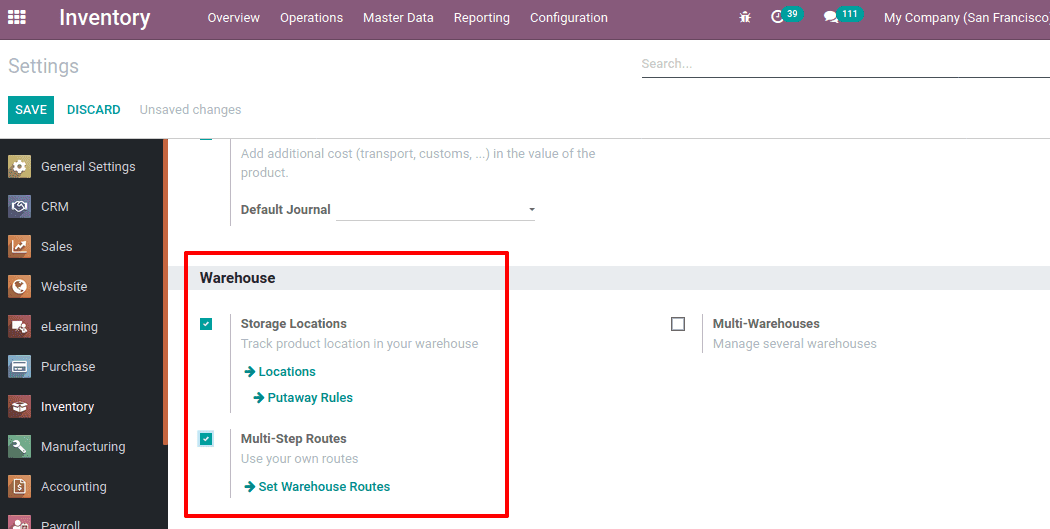

To achieve this the storage locations and multi-step routes in the warehouse configuration settings have to enabled.

Go To inventory > Configuration > Settings > Warehouse > enable storage locations and Multi-step Routes and Save.

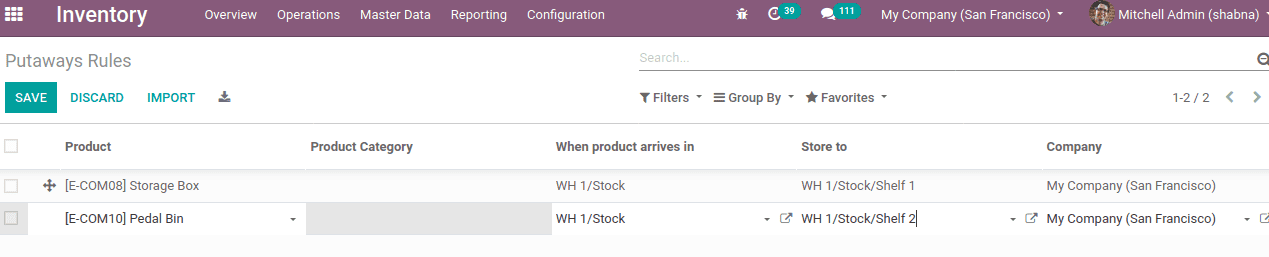

Now you can see ‘putaway rules’ in the configuration menu. To create a putaway rule, Go To inventory > Configuration > Settings > Warehouse Management > Putaway Rules.

It will open another window, click on CREATE to create putaway rules. Add products, location in which product arrives in and destination location where these products are stored and Save.

Here putaway rule created for two products Storage Box and Pedal Bin. The rule is set in such a way that when these products arrive at WH1/Stock, the Storage Box moves to Shelf 1 of the warehouse ( WH1/Stock/Shelf 1 ) and Pedal Bin moves to Shelf 2 of the warehouse ( WH1/Stock/Shelf 2 ).

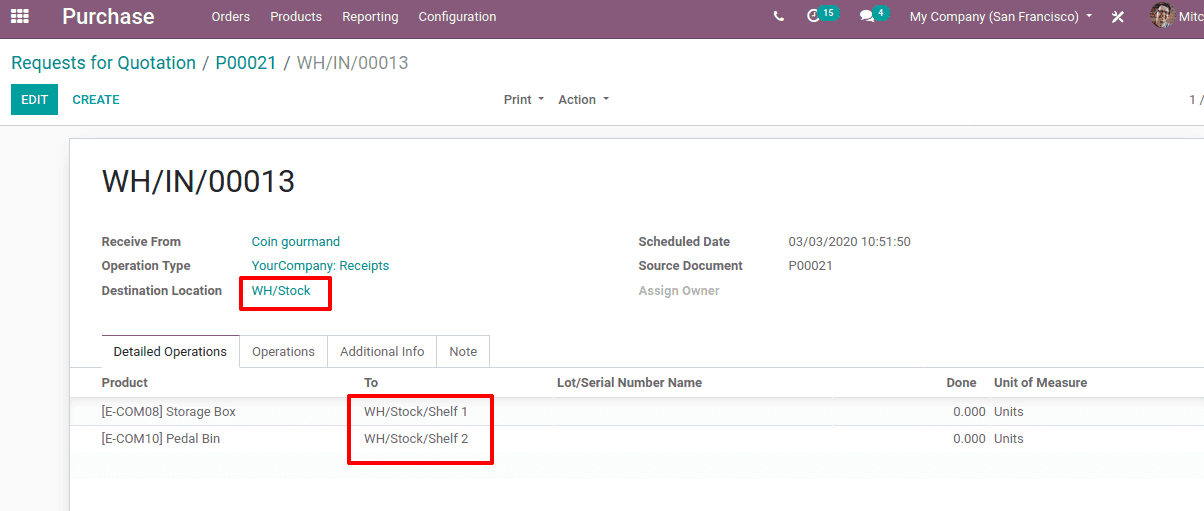

To know the product movement create a purchase order for these two products. Go To Purchase module > Orders > Purchase Orders > CREATE and confirm the order after adding the vendor and products.

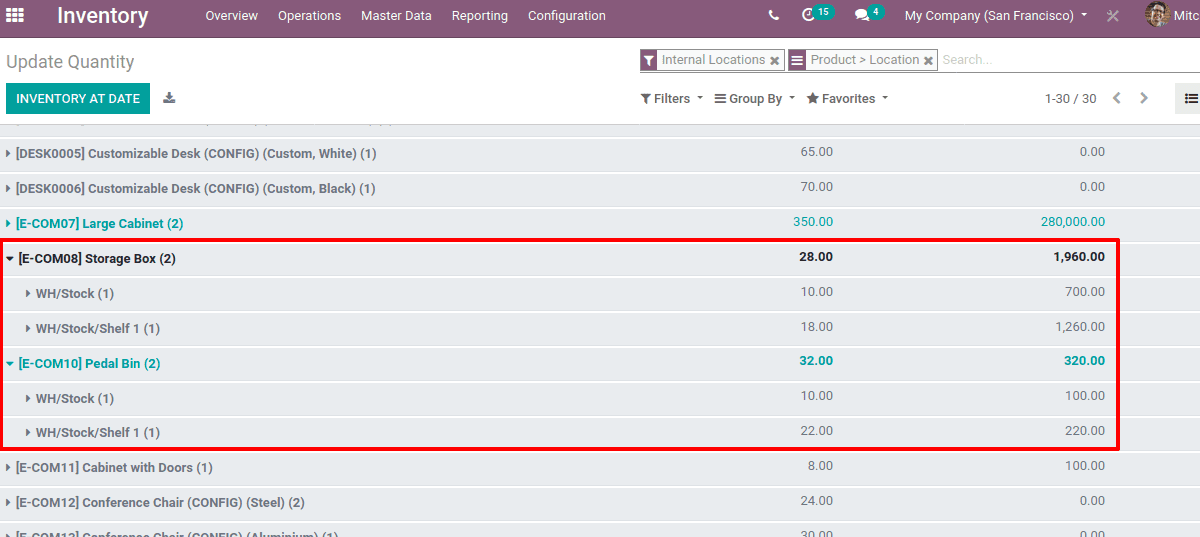

You can see the product movement inside the inventory report, Inventory > Reporting > Inventory Report.

Removal Strategies

In warehouse operations, Removal strategies are basically applied to choose the finest quality products on the basis of certain criteria. There are different removal strategies like FIFO, LIFO, FEFO etc. These strategies allow removal of products from the stock effectively and manage the stock without the accumulating the expired products

Configuration

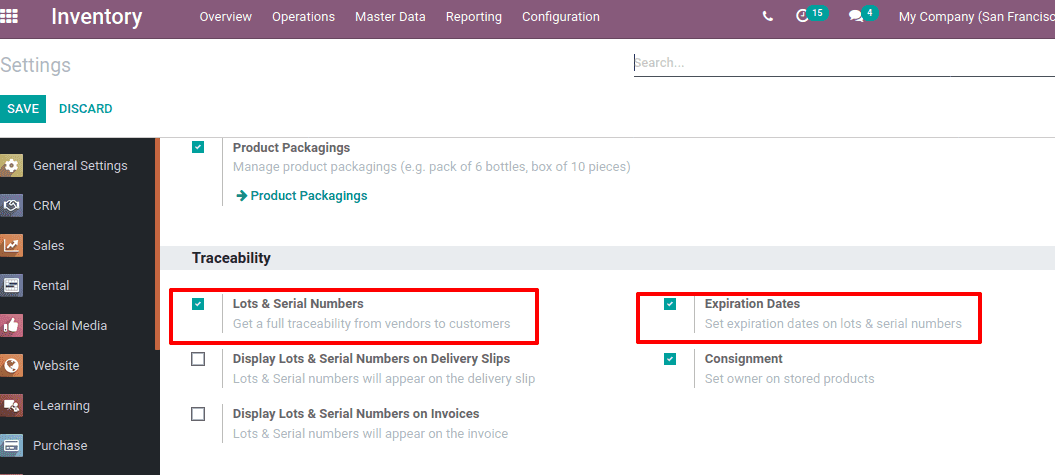

Go To Inventory > Configuration > Settings > Traceability > enable Lots & Serial Numbers and Expiration Dates

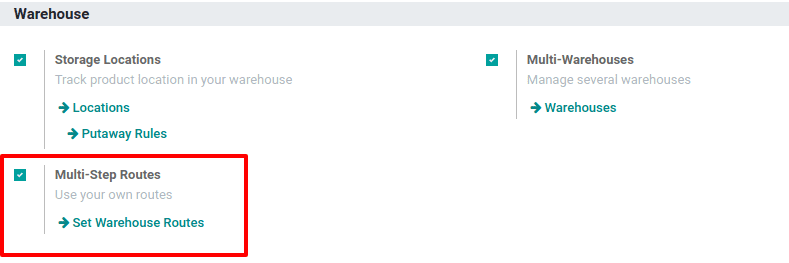

Also enable multi-step routes under warehouses, Inventory > Configuration > Settings > Warehouse > enable Multi-Step Routes

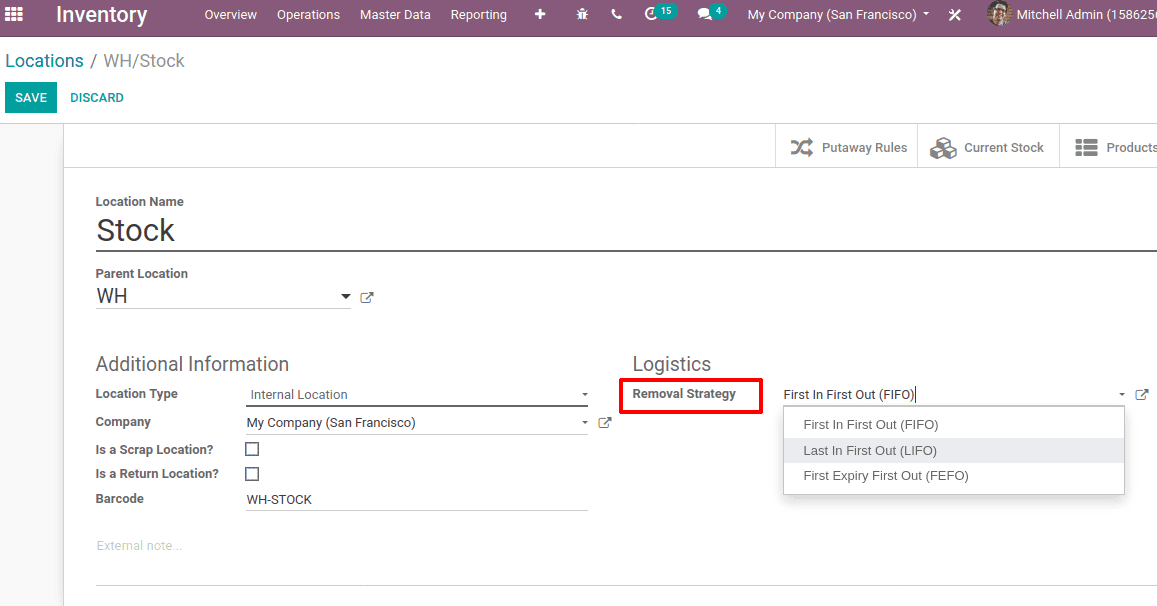

Now go to Inventory -> Configuration -> Warehouse Management -> Locations and choose the location for which you want to apply the removal strategy.

Under logistics, one can choose the removal strategy from the pop-up menu.

First In First OUT (FIFO) removal strategy: Those products that come first in the inventory are removed first. This method used for products that have a short demand cycle or get outdated soon

Last In Last Out (LIFO) removal strategy: Those products that come last in the inventory are removed last. This method is used for products having a longer life span.

First Expired First Out (FEFO) removal strategy: According to the expiry date, products shall be delivered from the warehouse.

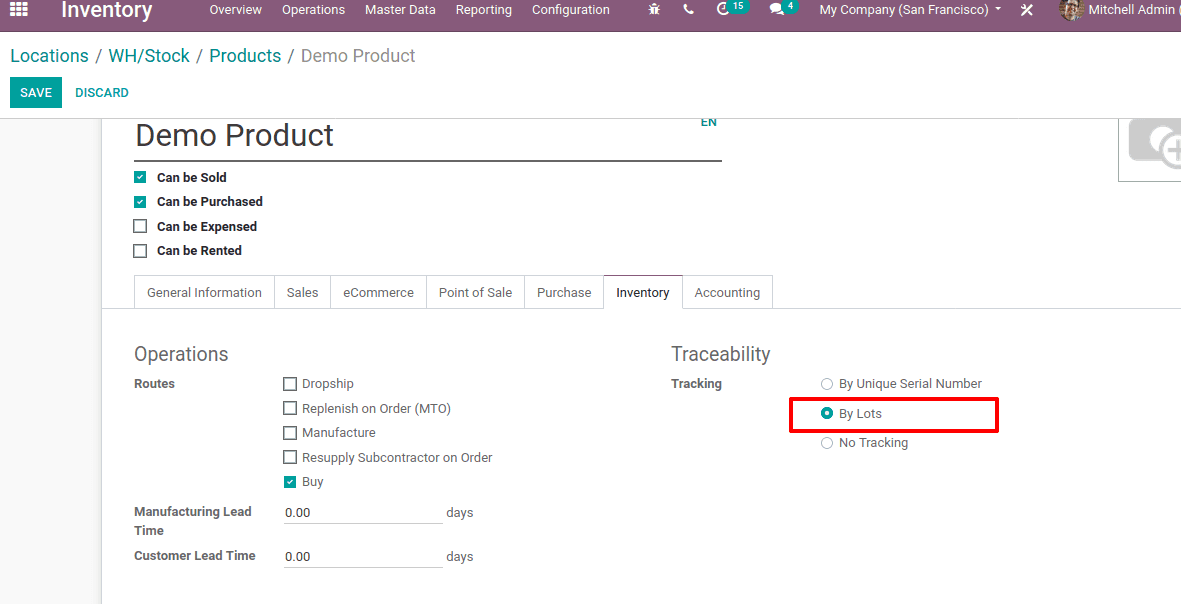

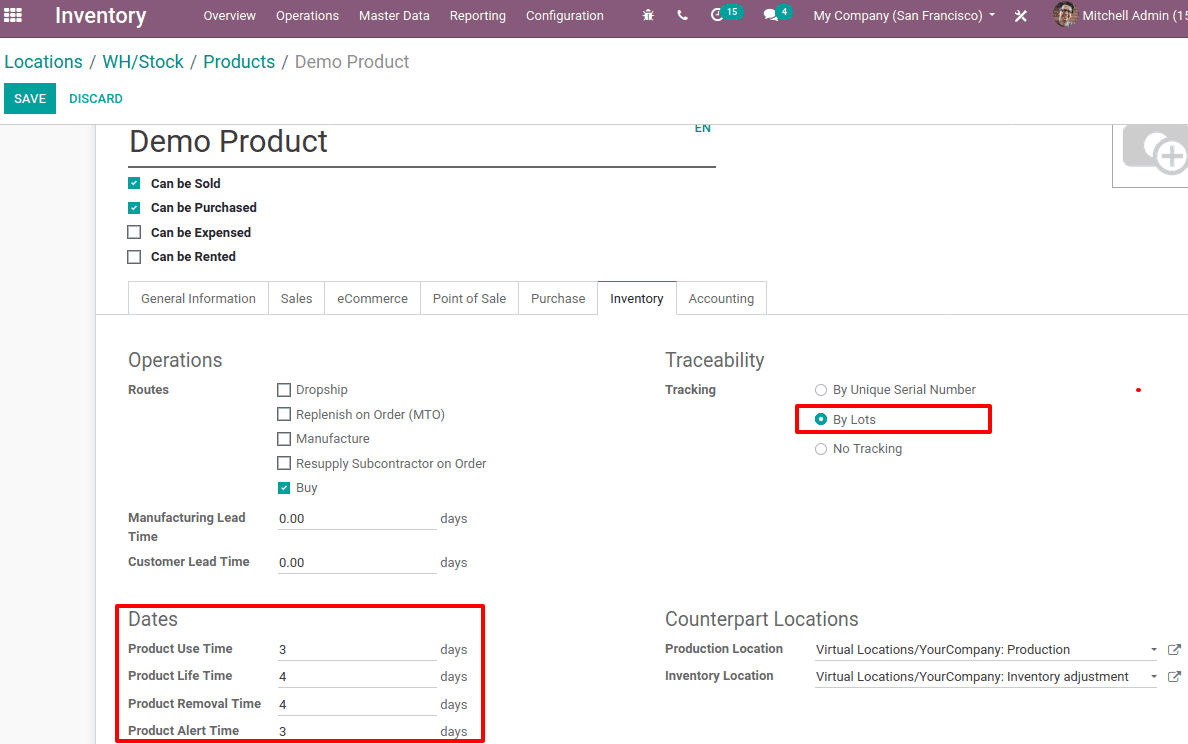

Now create a ‘Demo Product’ whose product type is ‘storable products’ and under inventory tracking chosen as ‘By Lots’. The quantity of the product on hand is zero.

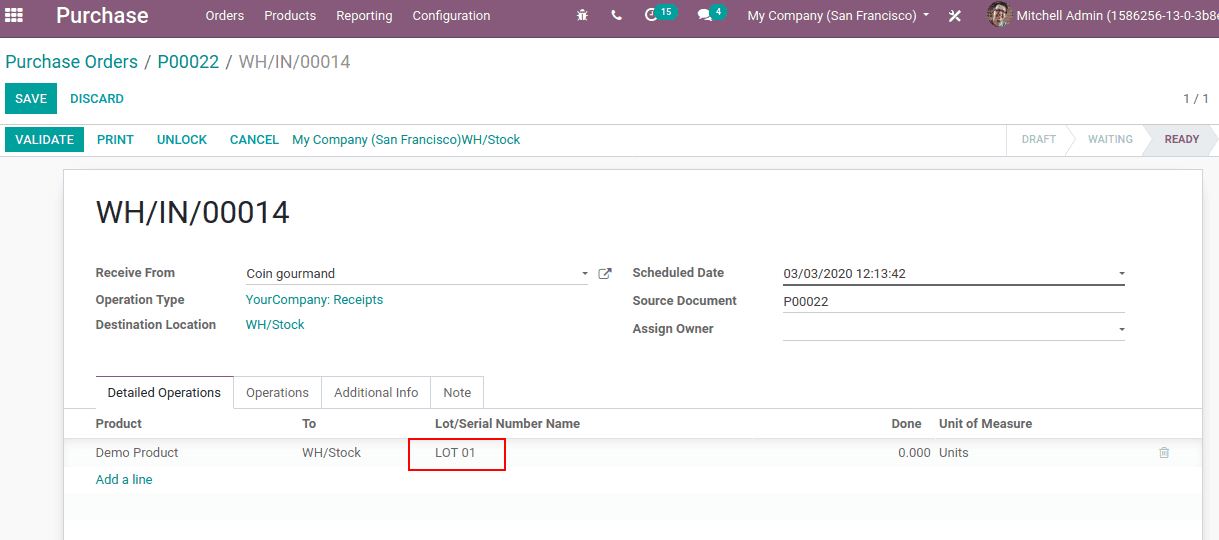

One has to create a purchase order to this ‘Demo Product’. Go to the purchase module and confirm the purchase order with a lot number ‘LOT 01’.

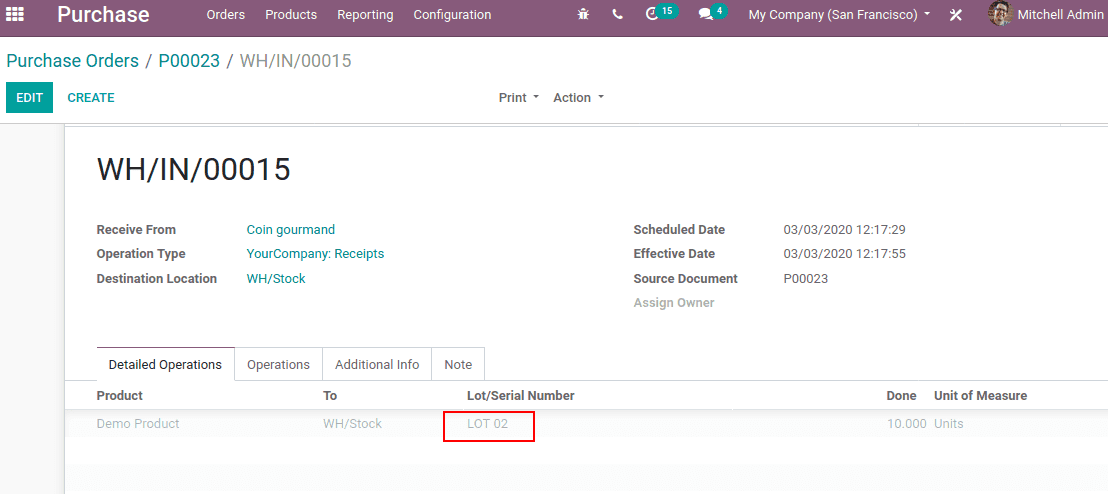

Create another purchase order with another lot ‘LOT 02’

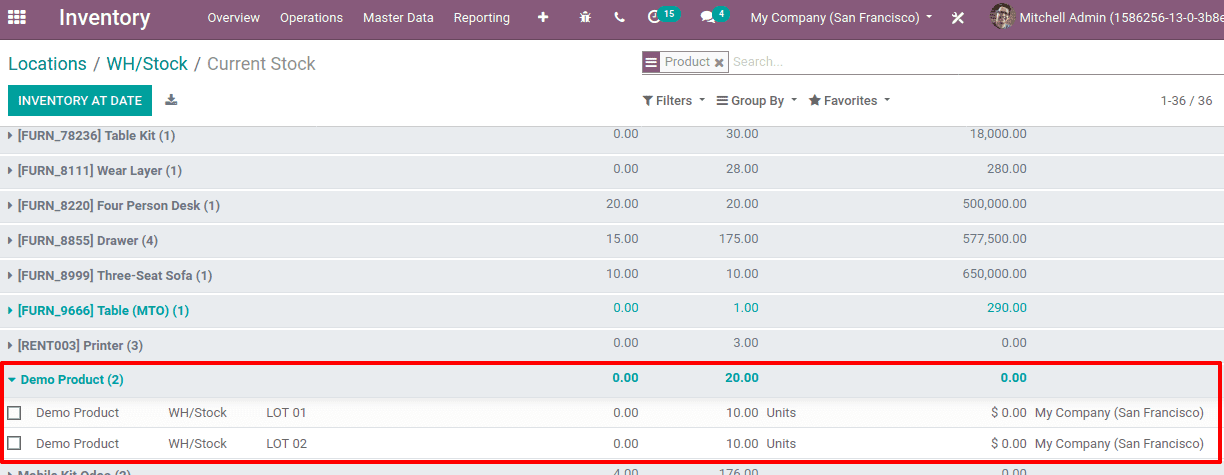

Since the removal strategy used as FIFO, when a sale order comes the products in the LOT 01 will move out. You can find the current stock of this product in the inventory location WH/Stock (Inventory > Configuration > Locations> WH/Stock> Current Stock)

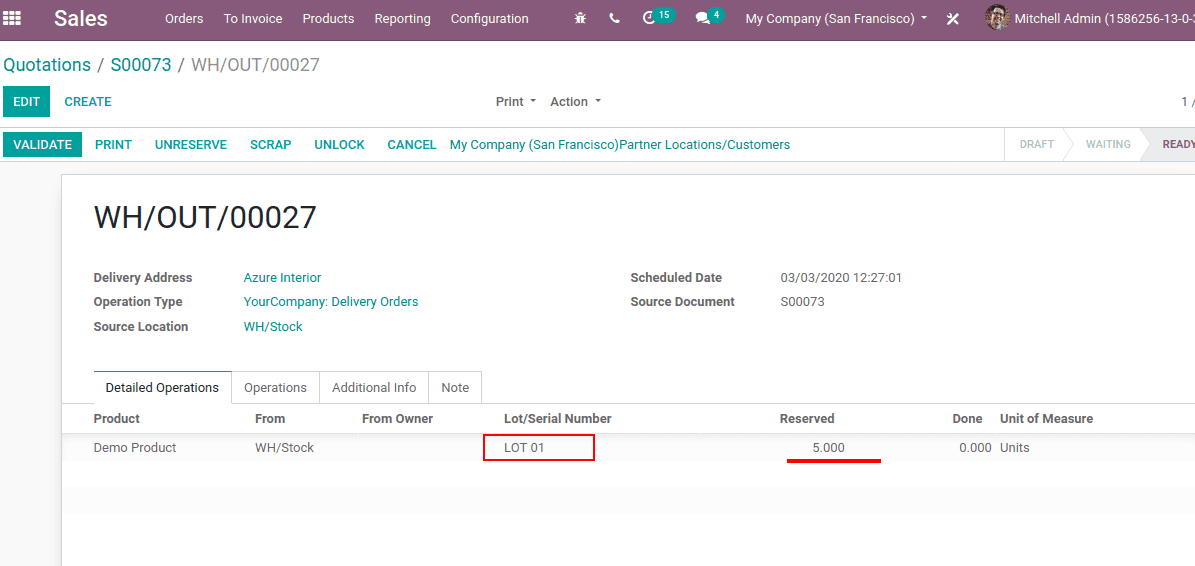

Now create a sale order for this Demo Product for 5 units, this will move from the product first purchased.

In the case of First Expired First Out (FEFO) removal strategy, we have to specify dates in the product form. If we fill this information in the product form, the dates will be automatically filled in, when we create lots for the product

So while validating a delivery order, the products will be moved from the stock of warehouse on the basis of the configured method.