Checking the quality of the product in a company is always better for the in-house as well as the outhouse operation of the firm. It’s the company’s responsibility to ensure that they deliver products of top quality and by the specifications as mentioned by them. To ensure this the companies should undergo a series of in-house quality checks during operations which should be done at various stages of operations of the company.

The quality analysis should not only be conducted on the purchased products but also among the manufactured products. The company may be manufacturing numerous products with various production lines of operations involving large numbers of machinery which would be synchronized to be operational to meet the production requirement. Managing the operations of these quality checks and analysis effectively should be done with utmost care and precision to attain the required output.

Nowadays the manufacturing operations are managed by business management solutions such as Enterprise and resource planning solutions which will provide the user with ultimate control over the manufacturing and Well as entire company operations. Odoo is the best ERP available today, with the capability of managing all company operations from a single open-source platform which is a reliable, cost-effective, and efficient solution for all business needs.

This blog will provide insight into how quality checks for the manufacturing process are being created and managed in Odoo 14.

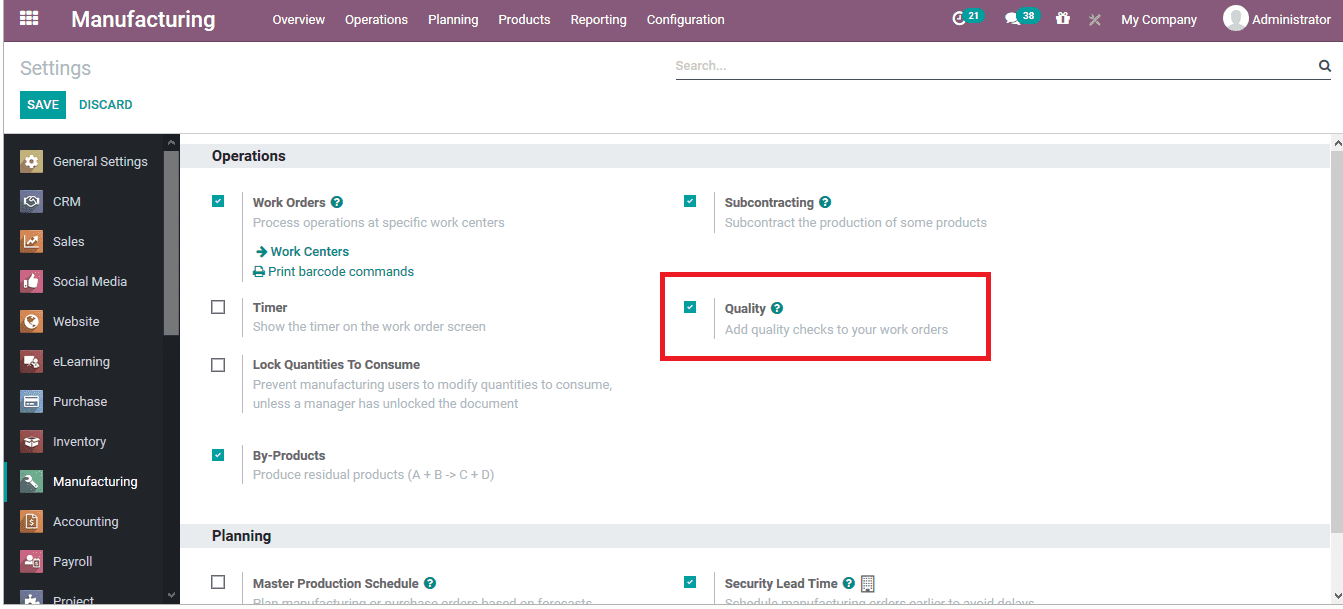

To establish quality checks in the manufacturing process, the user should initially install the quality application from the apps module. Secondly, as the application is installed the user should enable the quality option available in the operations of the settings menu of the manufacturing module. Doing these two will allow the user to create new quality checks, alerts, and points as well as using them in the manufacturing operations of the company.

Creating quality checks

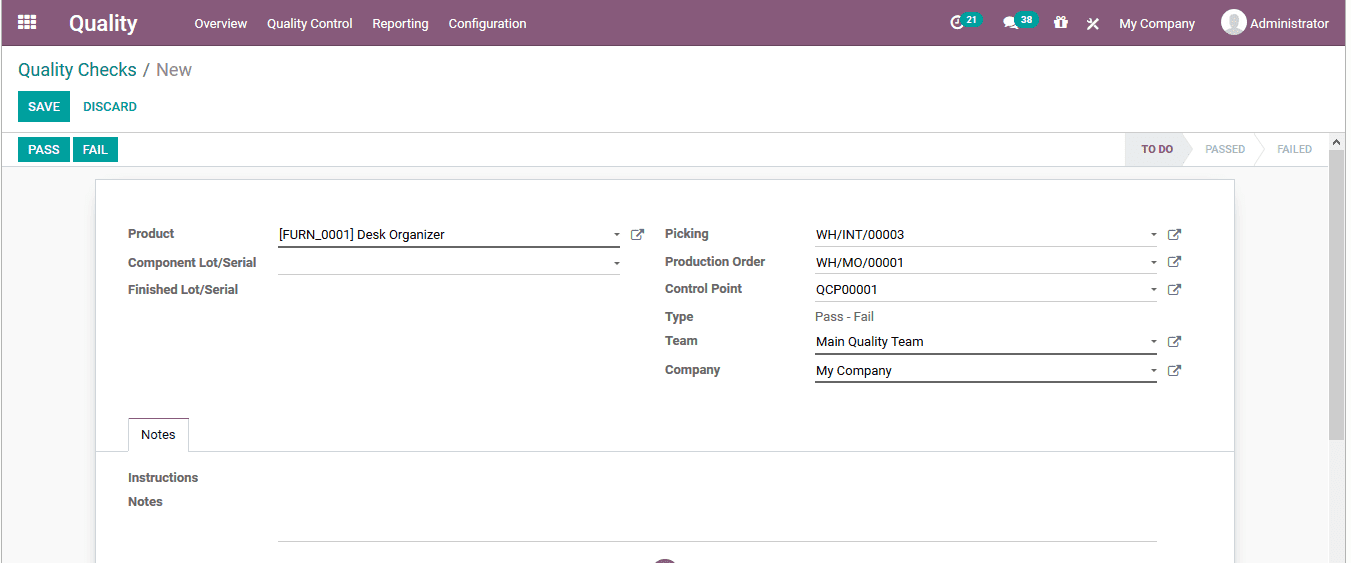

The user can create new quality checks in the quality model of the platform under the quality checks menu accessible for the quality control tab of the module dashboard. Here all the quality checks for the company operations whether its form manufacturing, purchase, or sales operations are well-described here and listed out. The user can also create new ones by declaring the attributes in the creation window of the new quality check. In the window, the user can assign a product, component, or serial/ lot number associated. In addition, the picking, production order, control point, type of quality check, and the team of operations in the company associated can be assigned.

The type of quality check can be assigned as text, take a picture, pass/ fail, register consumed materials, register by-product, print label, or measure. Where each type has its function functioning in the operations of the quality check operations conducted in the company operations.

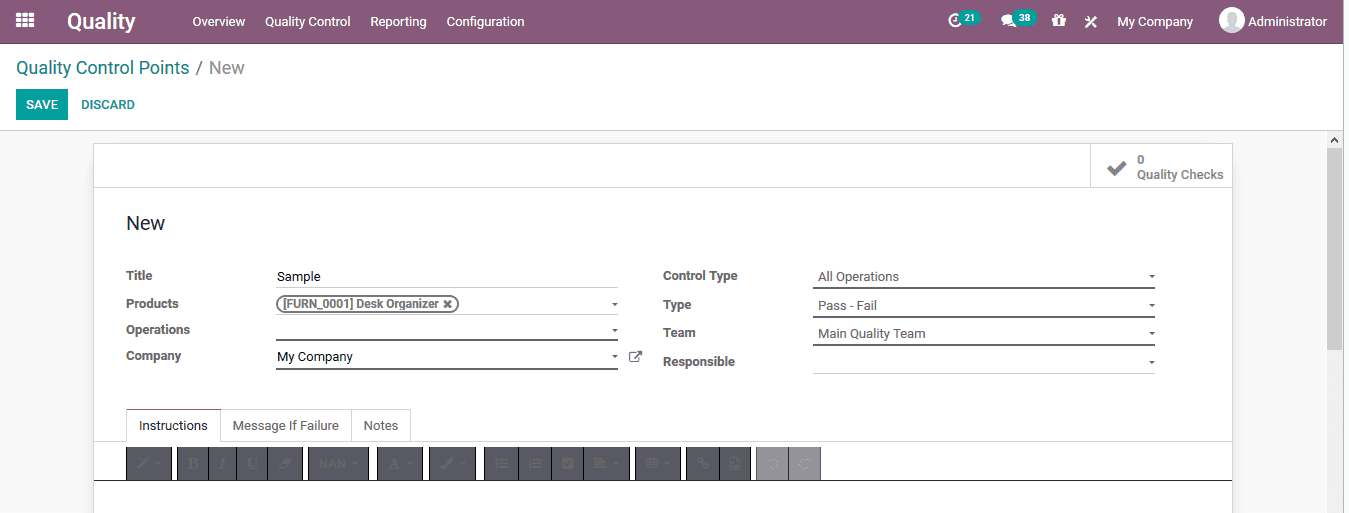

Assign quality control point

The quality control points for the manufacturing process can be assigned at the various stages of the production operations where the respective quality checks defined will be conducted. This methodology of Odoo quality check operation will allow the user to specify and customize the quality analysis operations of a product in real-time. The quality control points can be described in the quality control points window accessible from the quality control tab of the quality module. Here the title of the control point, a product associated with, operations in which the check is to be conducted, the company of operations if functioning the platform in multi-company operations, control type, type team and person responsible can be assigned.

In addition, the user can describe custom-made descriptions on the control points, message if the quality check is failed and the internal notes can be described.

Quality checks in manufacturing

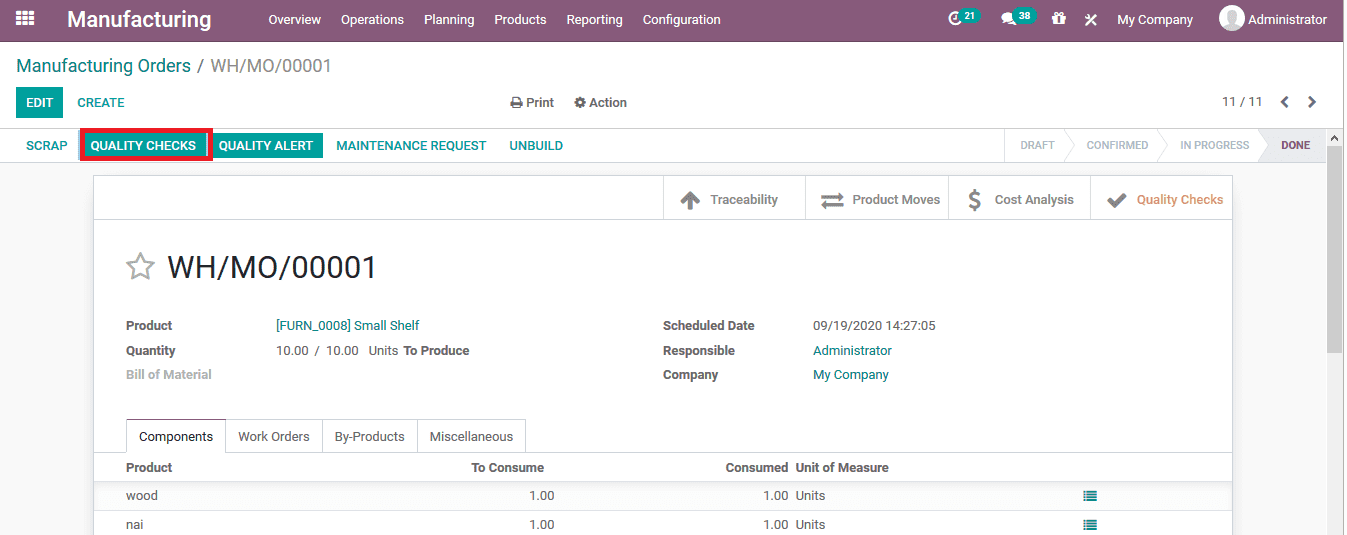

The quality checks and the quality points described in the platform can be assigned to the manufacturing process of operations which can be done in the manufacturing module of the platform. When a manufacturing order is created and confirmed while the process is in progress the user can select the quality check option available concerning each manufacturing order.

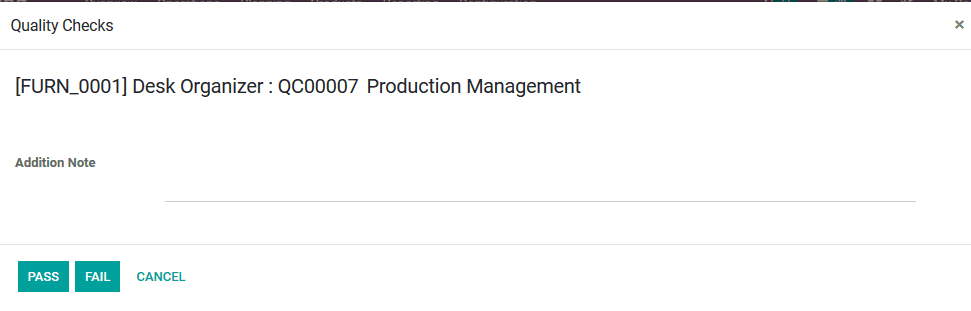

On selecting the quality checks option the user will be depicted with all the quality checks associated with the manufacturing order and the user can select the respective one and assign the status of the check conducted manually. Below is the depicted window on selecting a pass/fail quality check, where the user can assign the status and describe the same.

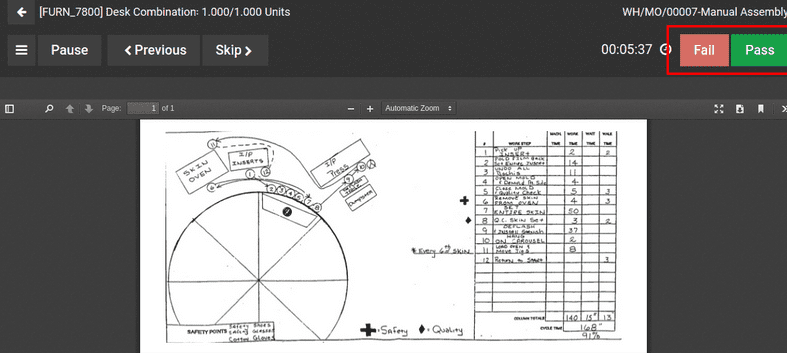

In addition, quality checks can be conducted during manufacturing operations taking place in the manufacturing process window. The quality checks can be selected from the menu available and the user can validate it based on the response provided.

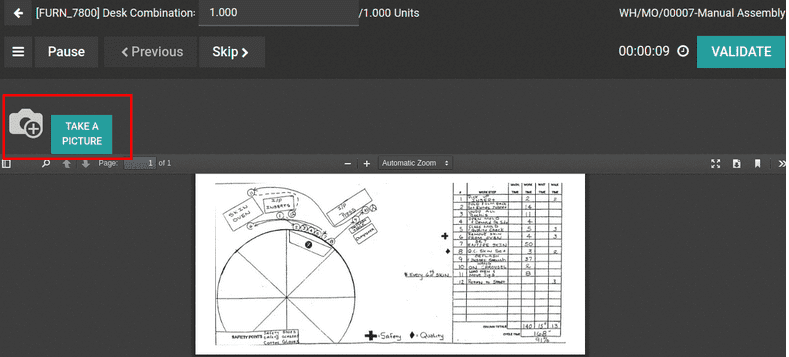

Additionally, here is the quality check operation which happens for a take a picture operation where the user will be depicted with the option to take a picture of the product, which can be done by a connected IoT device or an external camera.

The internal quality checks conducted on the manufacturing process will allow the user to send out only the well-reputed products by restricting thrones that are below the standardized description.

Read Blog: Odoo 14 ERP for Manufacturing