The uncompromisable aspect of the business is the maintenance of its service or product quality. We-defined controls are established to ensure that the quality is maintained. To standardize production and to maintain a quick and effective reaction to quality issues, these controls play a major role. It limits the room for error, especially in manufacturing. Bypassing the quality checks could result in more damaged production, resulting in rework or scrapping of the goods. This means more wastage and hence lesser profit.

Quality checks ensure that the manufactured products need no corrective actions to meet the expectations of the final product. Good quality control ensures better customer satisfaction. Quality testing can be introduced at various points along a production line and this would let us analyze where exactly is the problem and take action accordingly. The quality control used varies with industries. The quality checks performed will not be the same for food manufacturing units and furniture manufacturing units. The checkpoints, as well as the checking techniques, vary within industries.

The implementation of quality control in manufacturing can help induce a sense of quality maintenance among workers. The quality consciousness would help improve the production quality. Apart from that, the reduction in wastage and repair cut down production costs. There is the effective utilization of the materials. It also boosts the employee morale, as they are aware of working with better quality production. In cutting down production costs, improving customer satisfaction, and increasing sales, quality control can do a significant job.

We surely cannot think of eliminating quality control. But we sure can invest a little thought into improving the quality control process. For this we have automated systems that help you manage the quality control in your manufacturing with more efficiency and accuracy. The Odoo Quality module has features to define control points, generate alerts and perform quality checks.

We can look in detail at the configuration of the Quality module in Odoo.

Odoo Quality

From the Odoo apps install the Quality module under manufacturing.

Control points

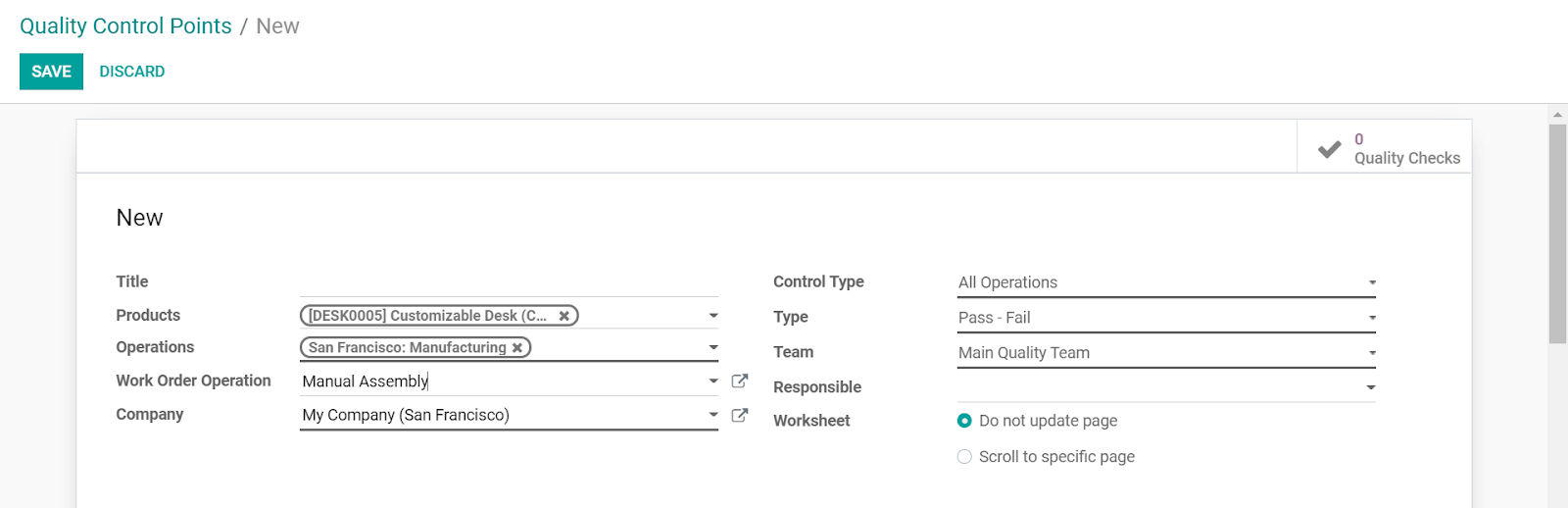

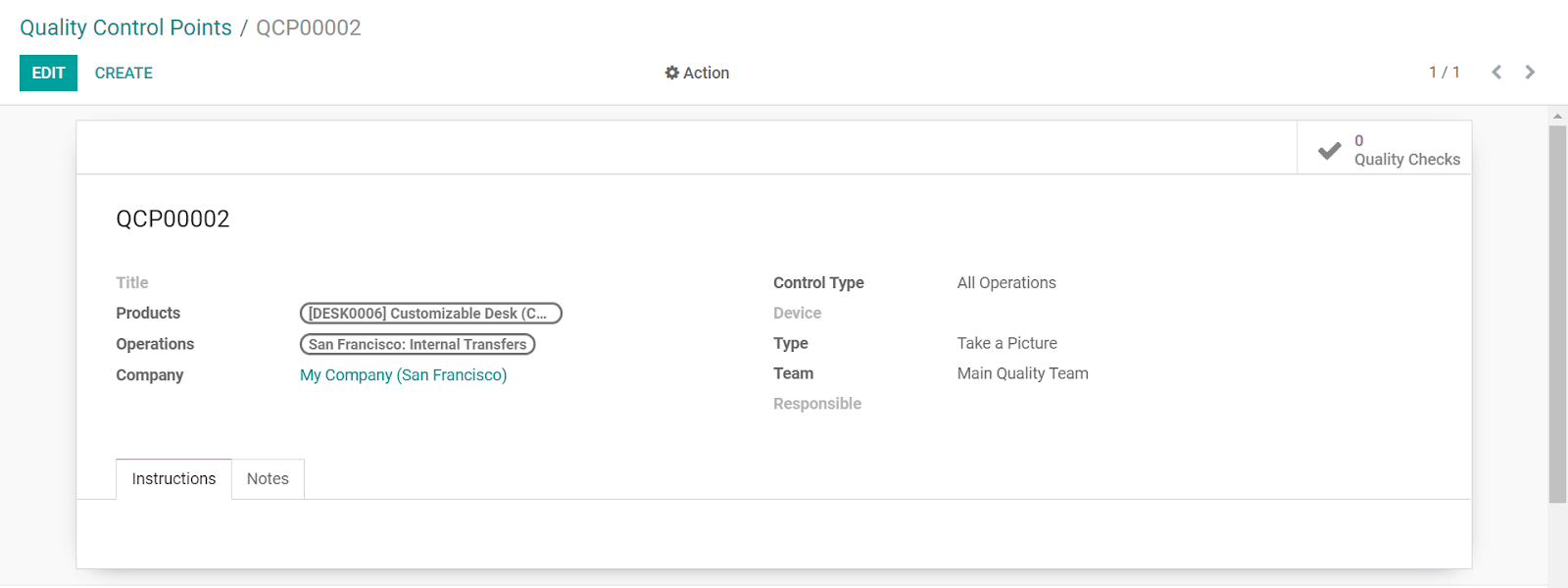

From the dashboard menu Quality Control, we can access the control points. We can define the quality control point. This would define the product and the operation stages at which the control should take place.

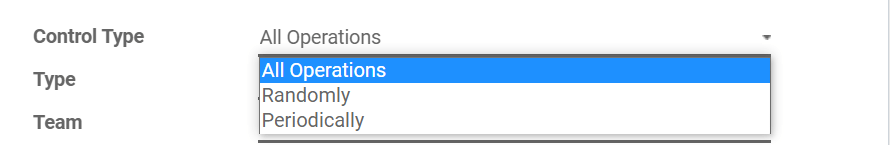

We can alter the control type to modify the frequency of quality control performed. We can choose to perform on all operations or on x% of the operation(randomly) or periodically at regular intervals.

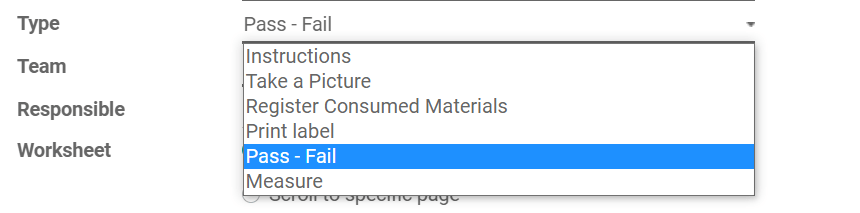

We can also define the type of quality check to be performed at the control point. The available types can be viewed from the drop-down menu and will define the quality check performed.

– Instruction: it allows the employers or managers to provide instructions to workers regarding the product. For example, we can remind packaging to use ‘handle with care’ stickers for fragile products.

– Take a picture: this instructs to take and add a picture of the product at any given stage of manufacturing or transfer. The quality check for the product will now have an option to add a picture.

– Register consumed materials: the lot/serial number of the products consumed in the manufacturing of the product is registered at this control point. You can avail of this option if we are working with routings. Routings can be set up in the manufacturing module.

– Print Label: as obvious from the type name, we can print the labels to be stuck on the products manufactured. You can simplify the process by connecting a printer.

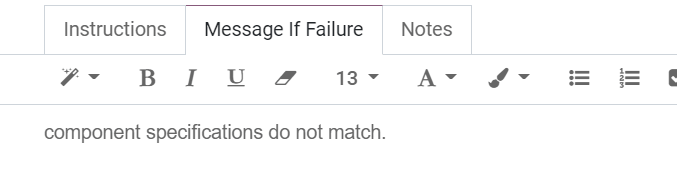

– Pass – fail: the specific pass or fail criteria are defined and the quality control is done based on the criteria. We can enter a fail message if the product does not meet the specific criteria.

– Measure: we can ask for the product to be measured as well as set a norm and tolerance criteria. This would allow us to ensure that the measurement criteria are met. We can also provide a tolerance range within which measurement is acceptable. We can provide a message for quality check failure, similar to the pass-fail type.

If we have created more than one quality team, ensure that the correct team is chosen for each point.

Generate quality alert

Quality alerts are generated to create alerts regarding the quality problems that were encountered during the manufacturing or during transfer.

Quality alert from manufacturing order

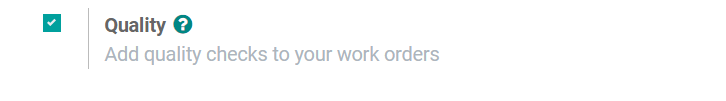

Creating a quality alert in manufacturing would involve two kinds of processes depending on the workflow of our manufacturing. We have to enable quality checks in the configuration of manufacturing.

We can now look at the steps to generate quality alerts for simple workflow (without work orders or routings)

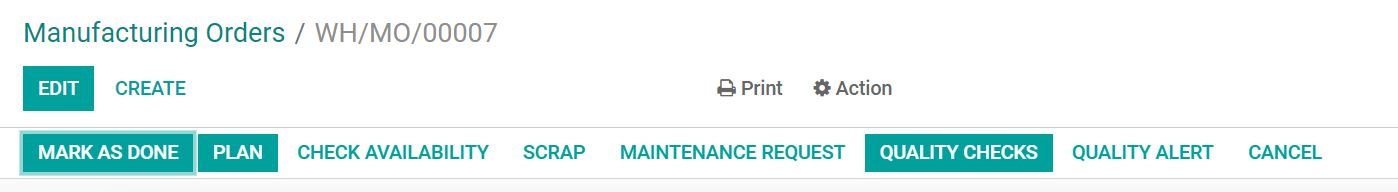

Open the manufacturing order for which the quality check is to be performed. If the product is configured in control points, the quality check and alert button would be visible from the particular manufacturing order. The quality check button can be used to run the defined quality check at that control point.

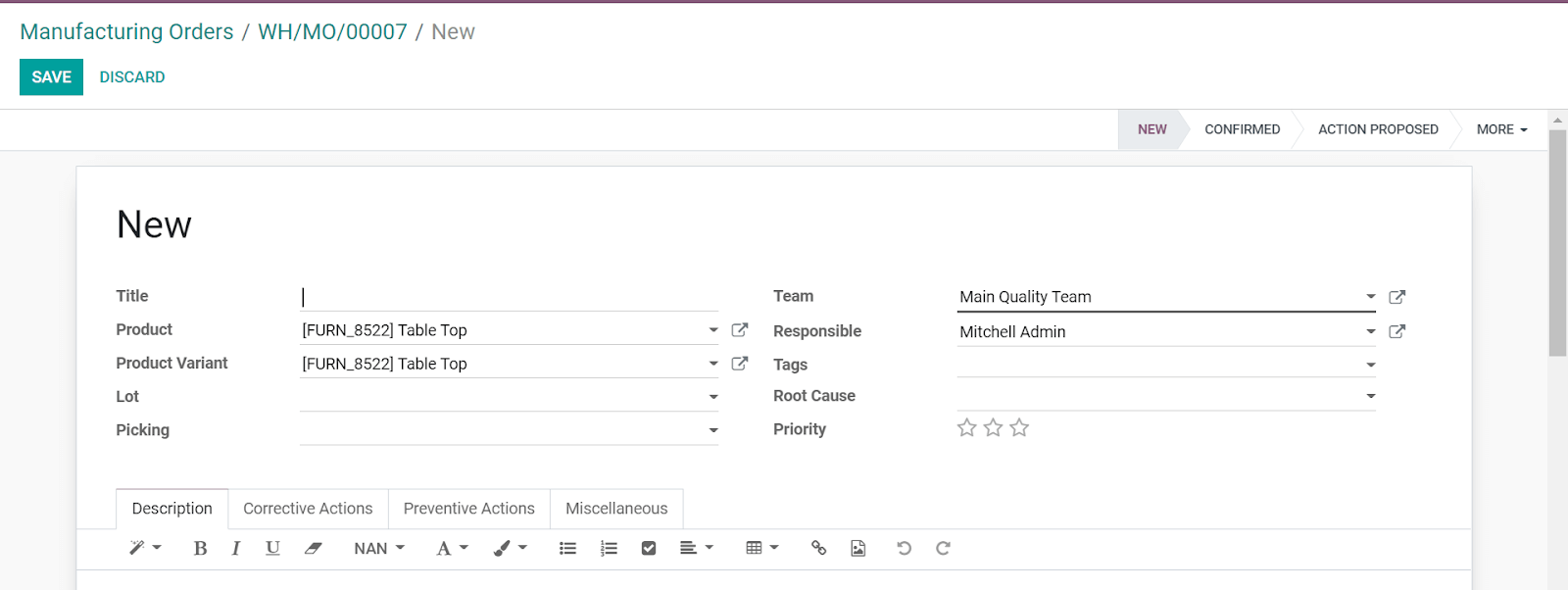

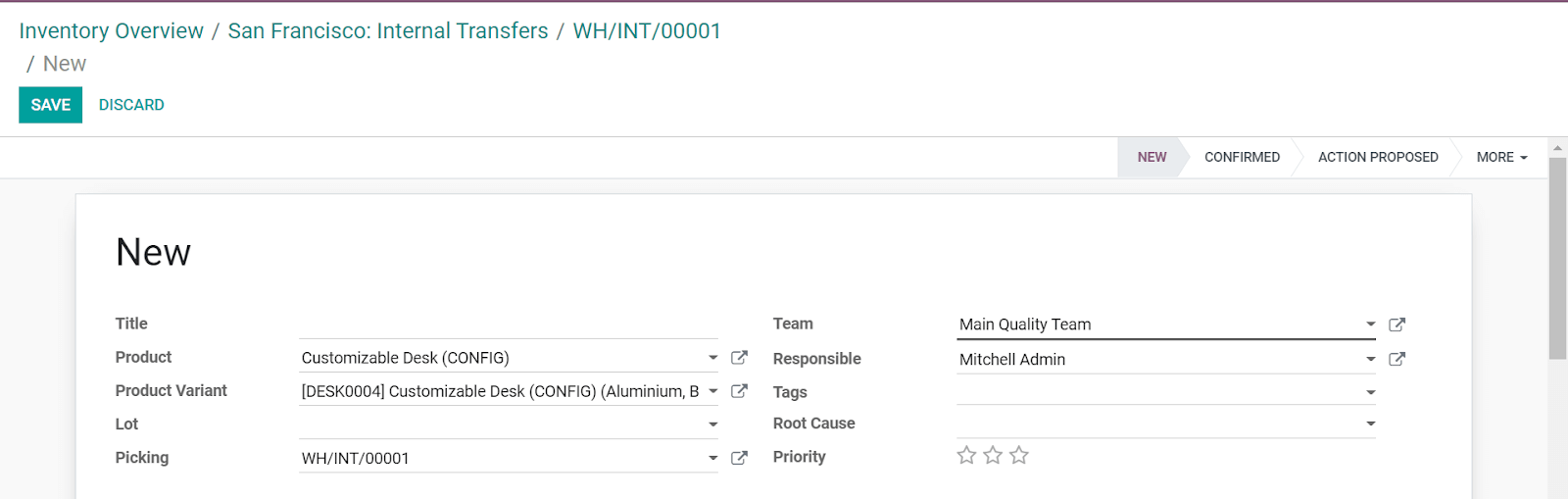

We can click on the quality alert to raise an alert about any issue. If the quality check is performed and the product fails, the Quality Alert would automatically be highlighted. We can save the details of the alert and it will assign the quality check to the assigned team. We can describe the corrective or preventive action to be taken for the product.

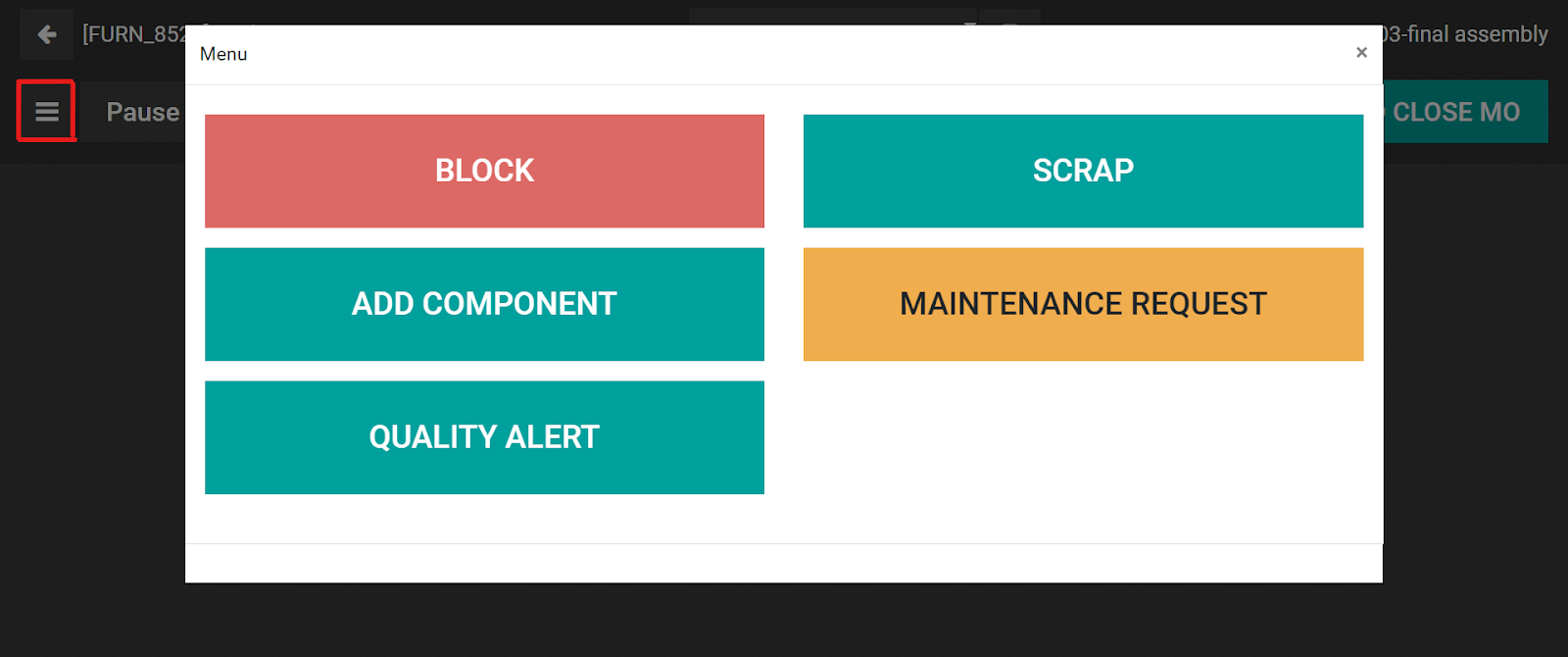

Alternatively, if it is a complex workflow with multiple routings, we follow a different process.

Once the manufacturing is divided into work orders we can open the work order for the product with defined quality control points. Then click on more options from the highlighted button, as shown in the image below, to receive the pop-up for various actions to be performed. We can click on the quality alert to create a new alert. The quality check is done when the work order is processed.

These are the two different processes of generating quality alerts.

Quality alerts from transfers

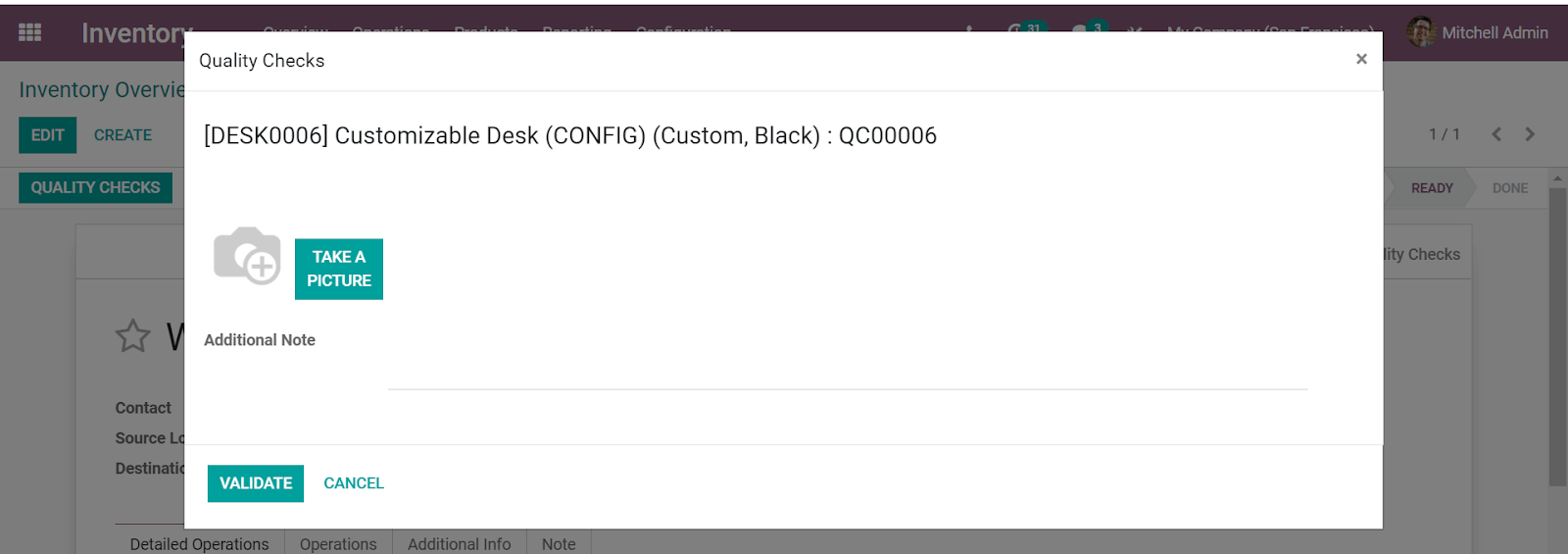

We have to ensure that we have defined a product and its operation type as one of the transfer operations. After doing so we can create a new transfer for the specific product in the inventory. In the image, we have defined the operation type as an internal transfer in the control point for the product defined.

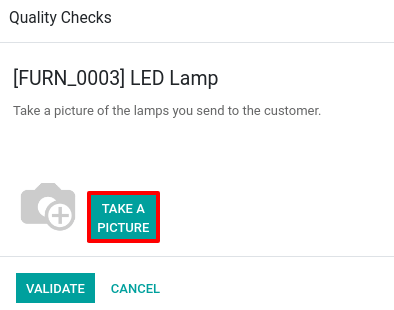

Now create a new internal transfer for the product in inventory and save. we can view the buttons for quality check and alert for the product in the inventory window of the product in the internal transfer. We can opt for a quality check and once the quality check is performed we can create alerts for the same if necessary. The quality control type was defined to take a picture and the subsequent window for performing the check would appear.

We can validate the quality check and in case of concerns, we will create a new alert.

This would be the process of managing and controlling the quality checks with Odoo. you can configure measuring devices, cameras, and so on to make the quality checks easier.

Watch Video:

[wpcc-iframe loading=”lazy” src=”https://cdn.iframe.ly/2UhqGfD?playerjs=1&click_to_play=true” style=”border: 0; top: 0; left: 0; width: 100%; height: 100%; position: absolute;” allowfullscreen=”” scrolling=”no” allow=”autoplay *; encrypted-media *; accelerometer; clipboard-write; gyroscope; picture-in-picture”]