Simply said, manufacturing is the process of bringing component pieces together and turning them into a finished product. However, completing the manufacturing process is a difficult task due to the various types of components and procedures involved. We must examine the quality of the manufactured product in each operation, as well as maintain and repair the used equipment.

Manufacturing functions differently for different kinds of businesses, depending on the raw part utilized, the operations done, and the ultimate product produced. And each of them has different requirements and risks. In Odoo, the Manufacturing module handles the entire process together.

Let us see how Odoo manufacturing helps in building machines

Work Centers

Manufacturing is not an easy activity; we must perform several procedures in order to complete the assigned task.

As a result, we require a work area to complete a manufacturing process. These workspaces, in which we do various activities, are referred to as work centers in the manufacturing process.

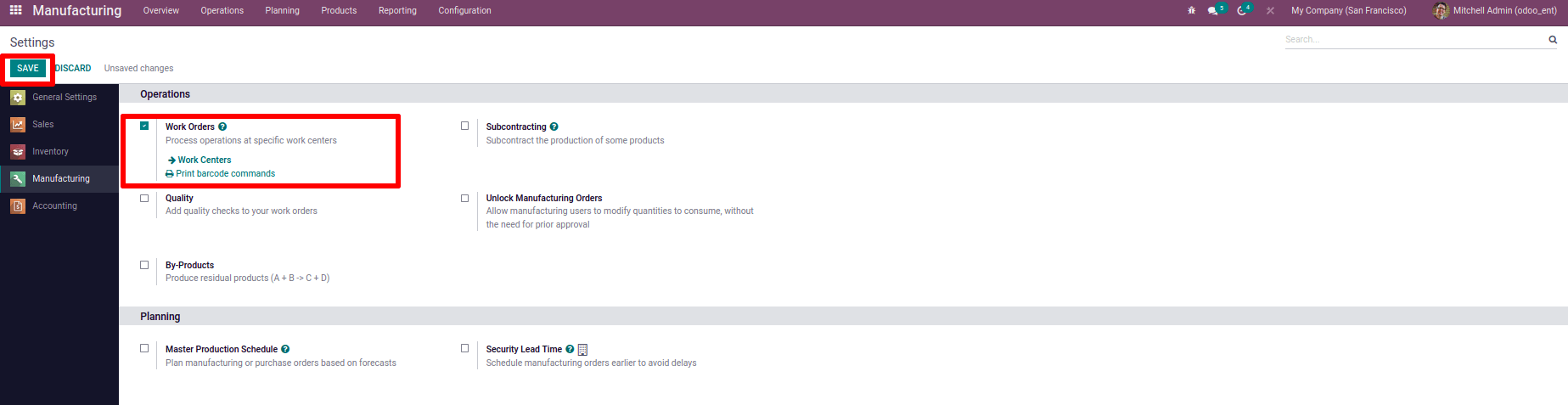

To create a work center, we must first set it up.

: Configuration > Settings > Work center

Enable work center and save.

Then, under the configuration tab, you’ll see the work center option.

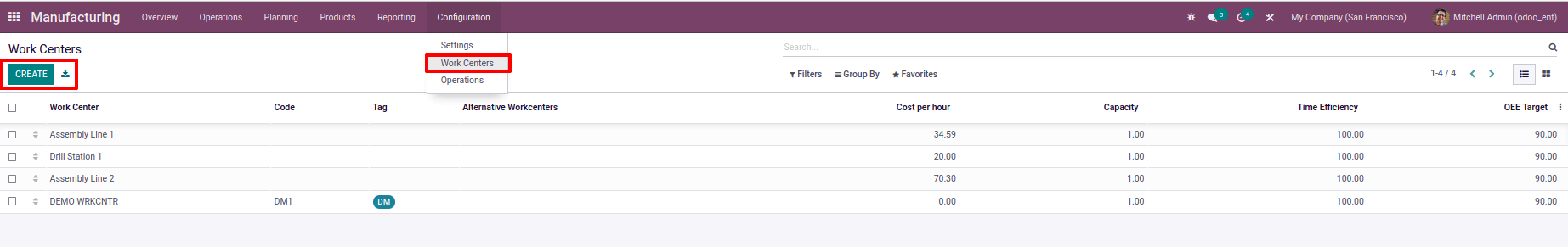

Select the work center from the drop-down menu; we can see previously created work centers there.

:Configuration > Work center

To construct our own work center for our manufacturing, click the Create button.

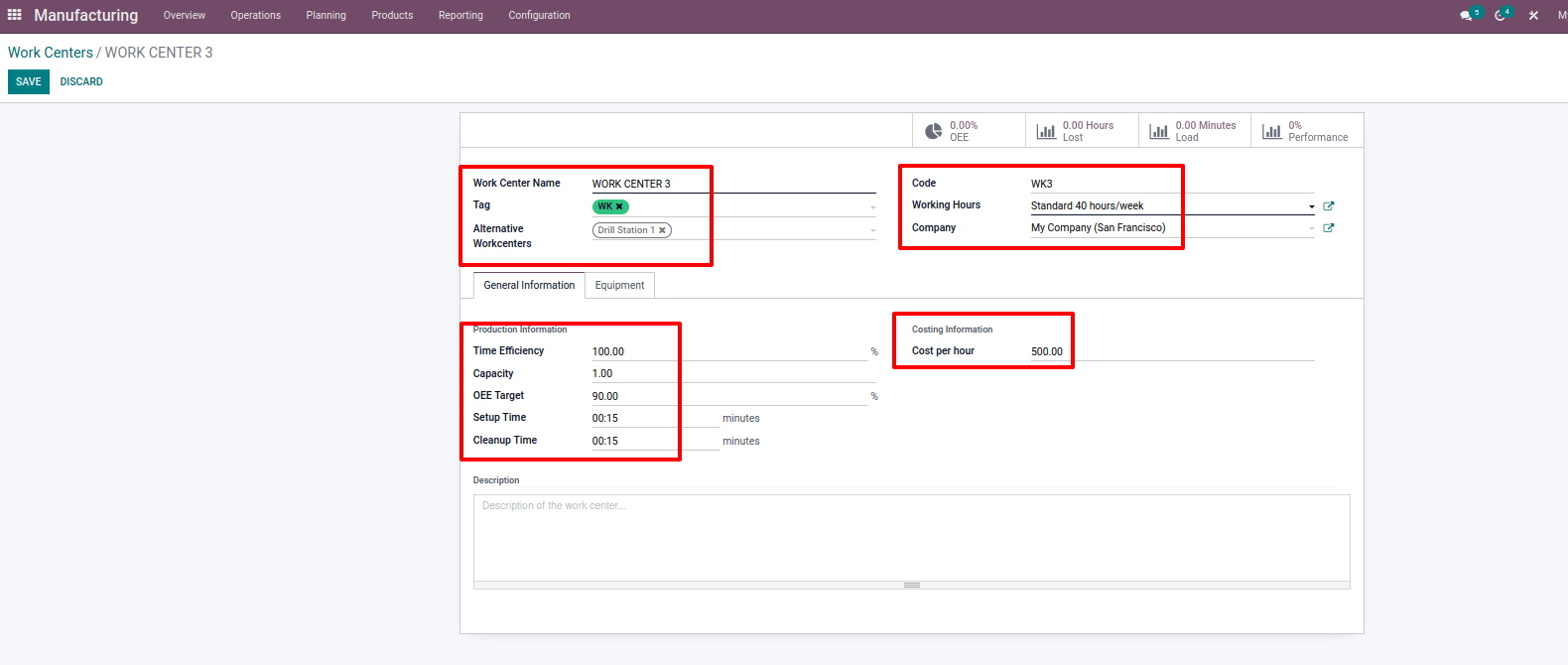

We must enter work center details such as Name, Alternative Work Center, Tag, Code, Working Hours, Company, General Information, and Equipment specifics when constructing a new Work Center.

Alternative Work Center: This work center can be used for operations when the primary work center is either overburdened or suffering technical issues.

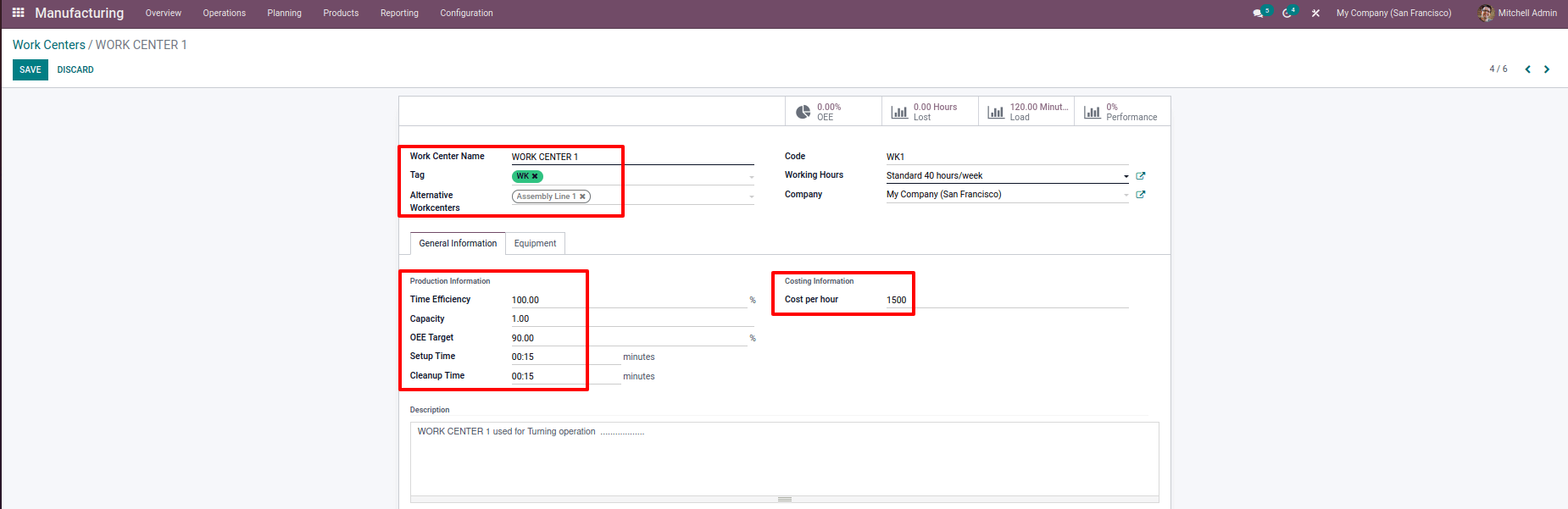

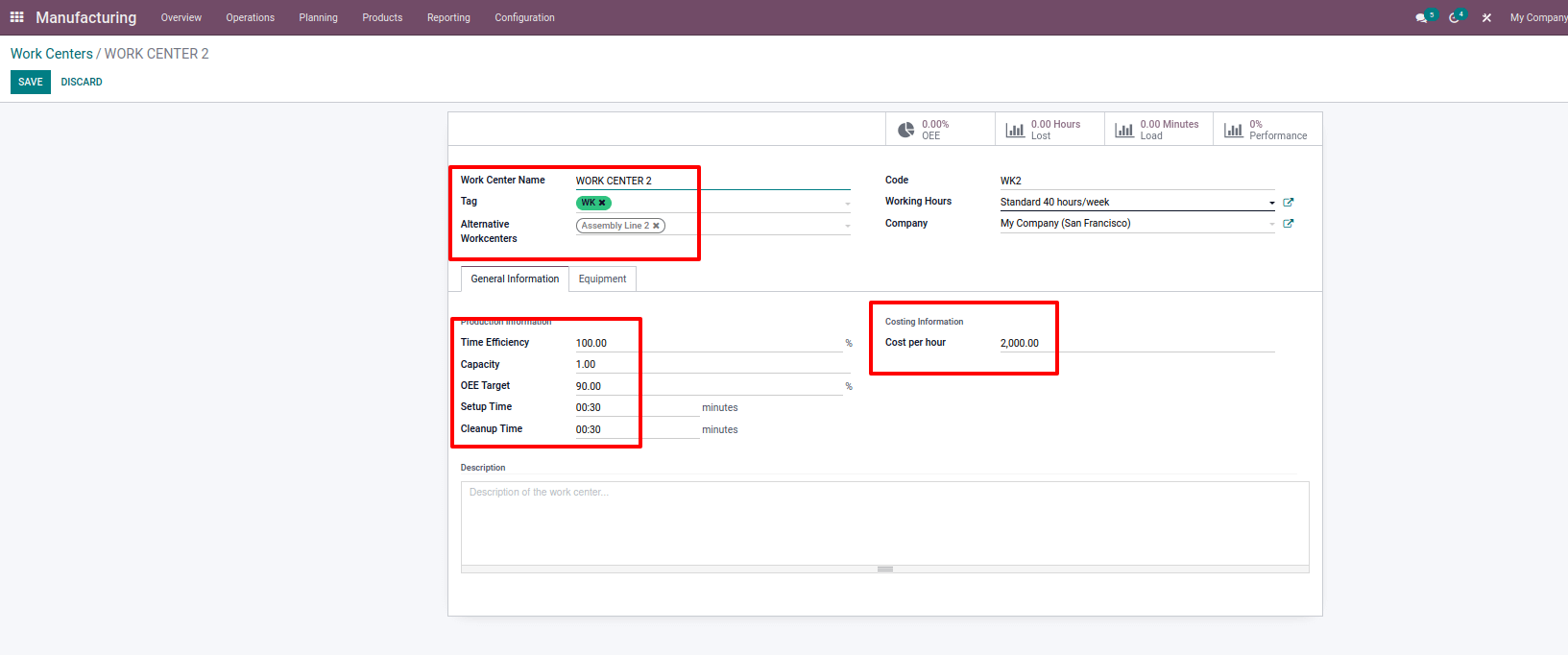

Here, three work centers are being created to perform three separate operations. Work center 1, Work center 2, Work center 3.

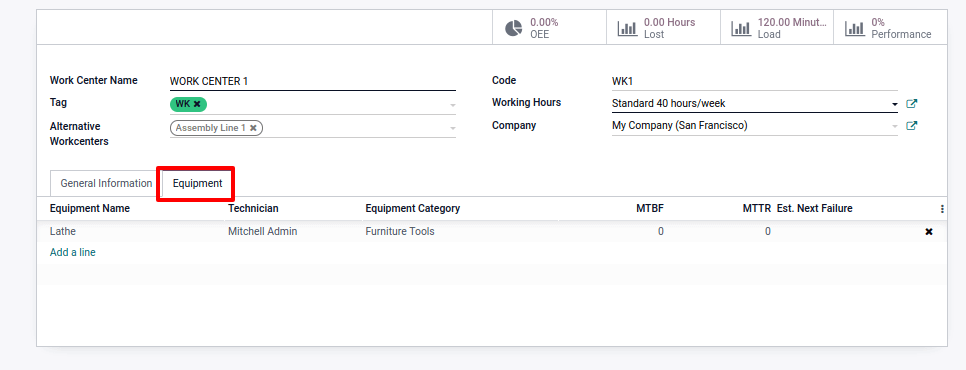

Work center 1 (code WK1) takes 15 minutes to set up and clean up and costs 1500 per hour. An alternative work center with the Assembly line and Lathe was added to the equipment field.

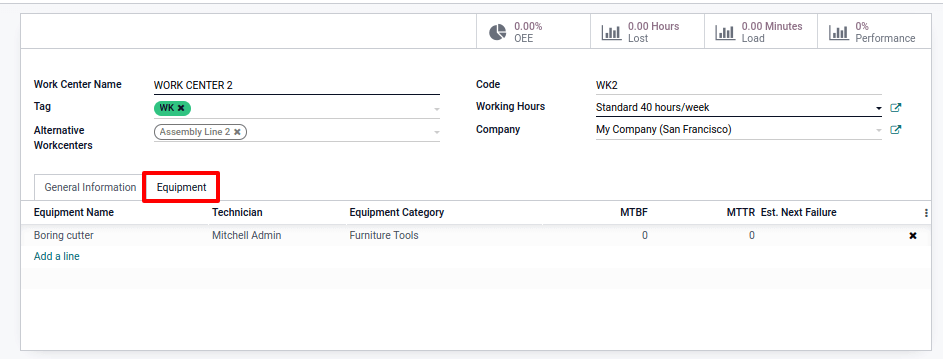

Setup and cleanup time for Work Center 2 is 30 minutes each, with an hourly cost of 2,000 and the use of a boring cutter. An alternative work center is Assembly line 2.

In work center 3, no equipment was used, and cleanup and setup took 15 minutes. An alternative work center is Drillstation 1.

Bill of Materials

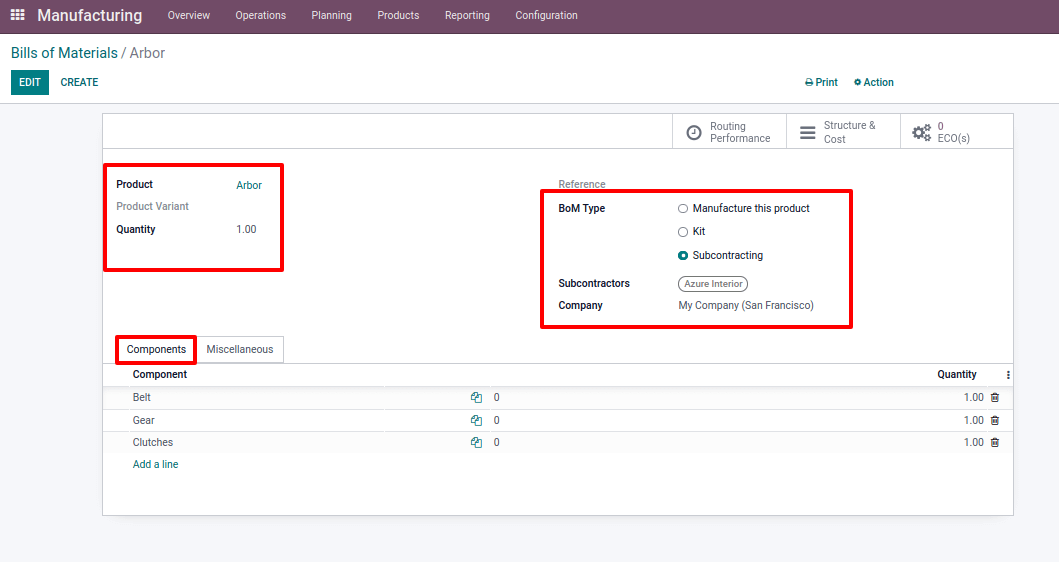

A bill of material must be created before a product may be manufactured. We can include components used in the manufacturing process as well as operations to be done during the production process in a bill of material. From here, we may construct three different types of bills of materials.

Subcontracting :

If we are unable to produce all of our products in-house, We can outsource some of them. For this, we can place a subcontracting order.

Go to Configuration > Settings > Subcontracting and enable Subcontracting and Save it.

It is necessary to add a subcontractor in BoM and for product ‘Arbor’ enable route ‘buy’ and a vendor who is also listed in the product’s purchasing tab. For the components, in product form under the inventory tab, Routes ‘Resupply Subcontractor on Order” must be enabled. Save the page once you have finished adding components.

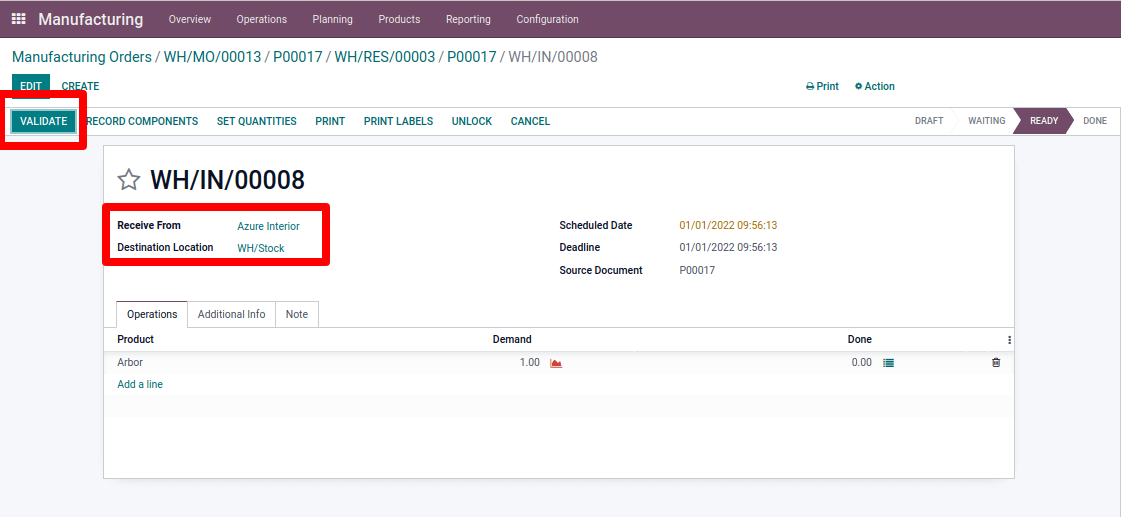

You should do the confirmation of receipt upon delivery of the product

Manufacturing :

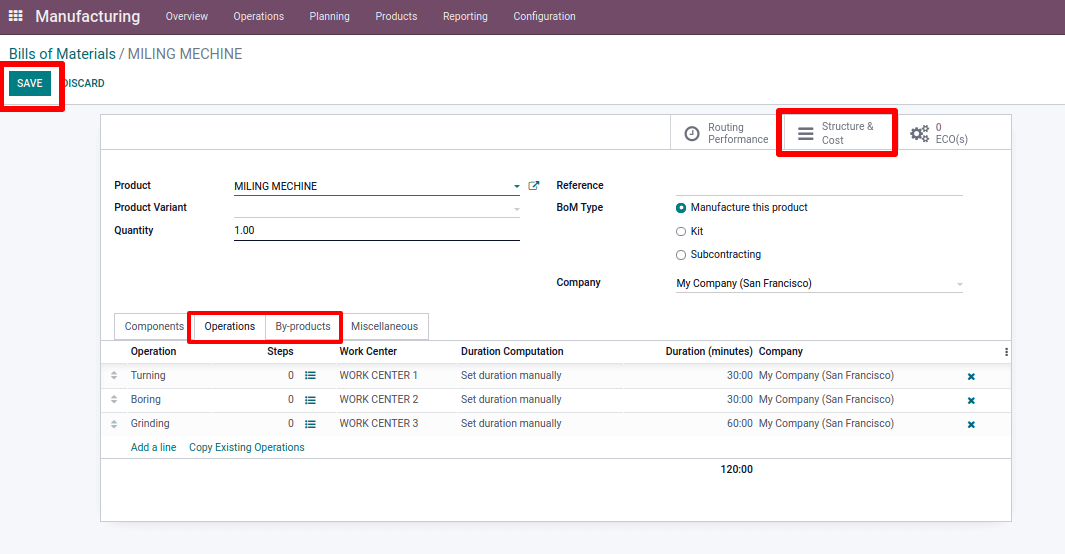

In the manufacturing process description Product information, components, and operations should all be included. There’s a field for adding Consumed operations, where we may specify which operation a specific component was used in.

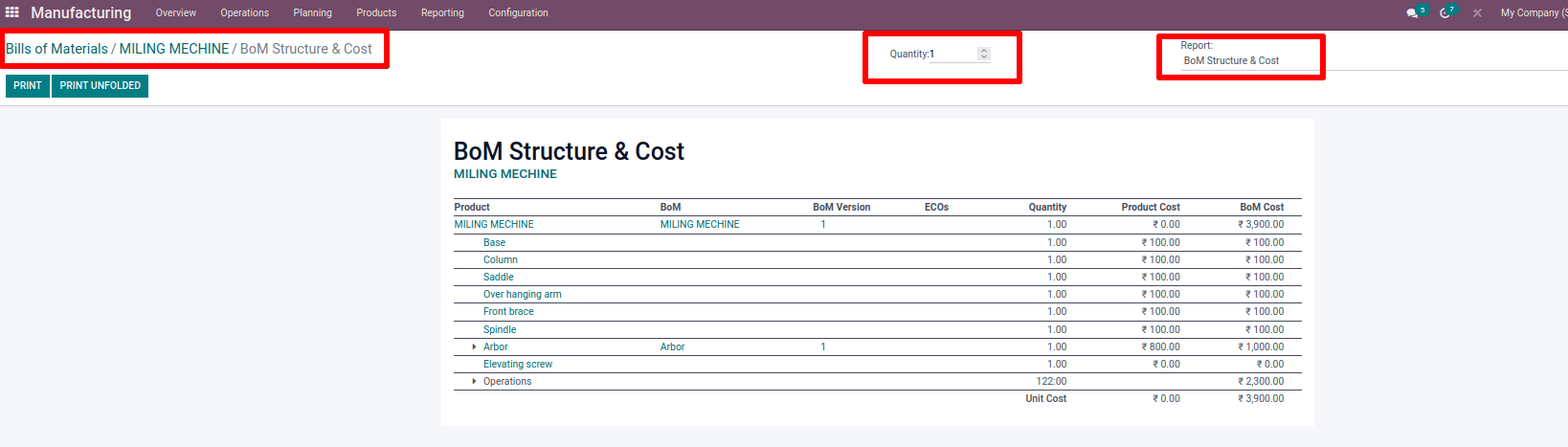

Then save it. It’s simple to estimate the Structure and cost of a bill of material for multiple products from the smart tab after saving.

Quality

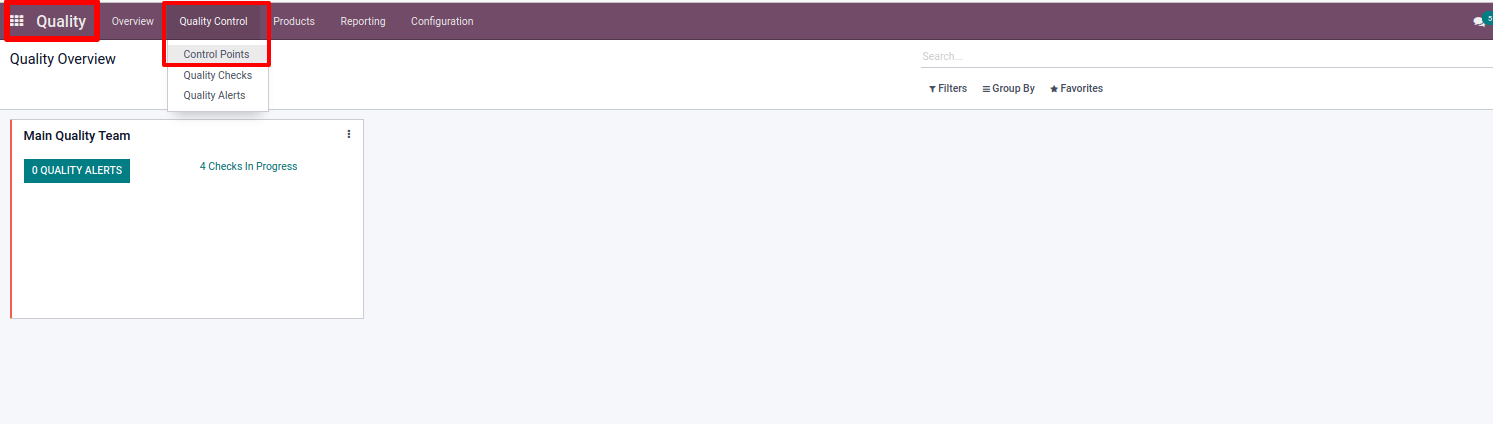

We may use the Odoo quality module to evaluate product quality after each action is completed. We need to construct quality control points in order to add quality checks.

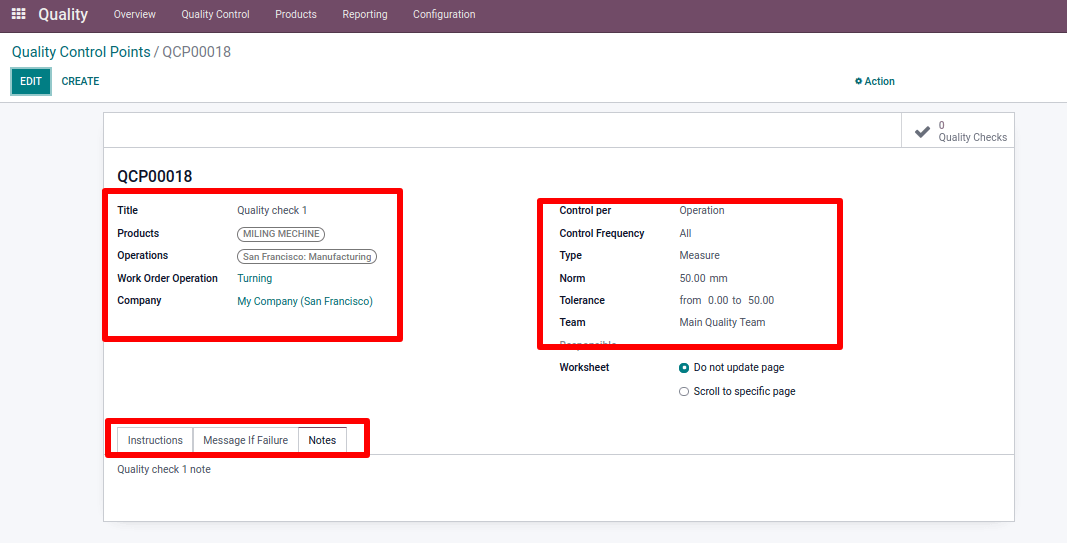

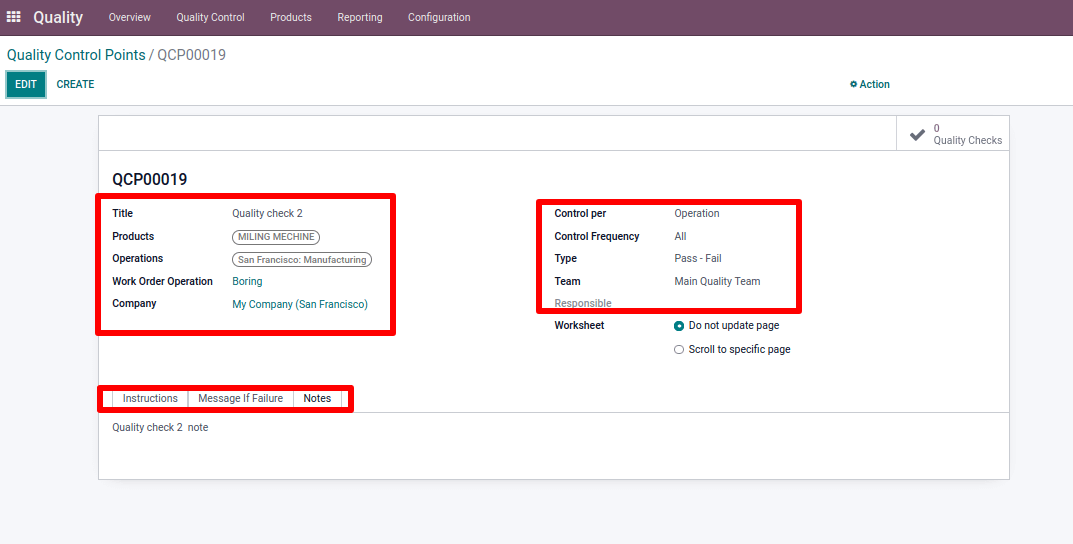

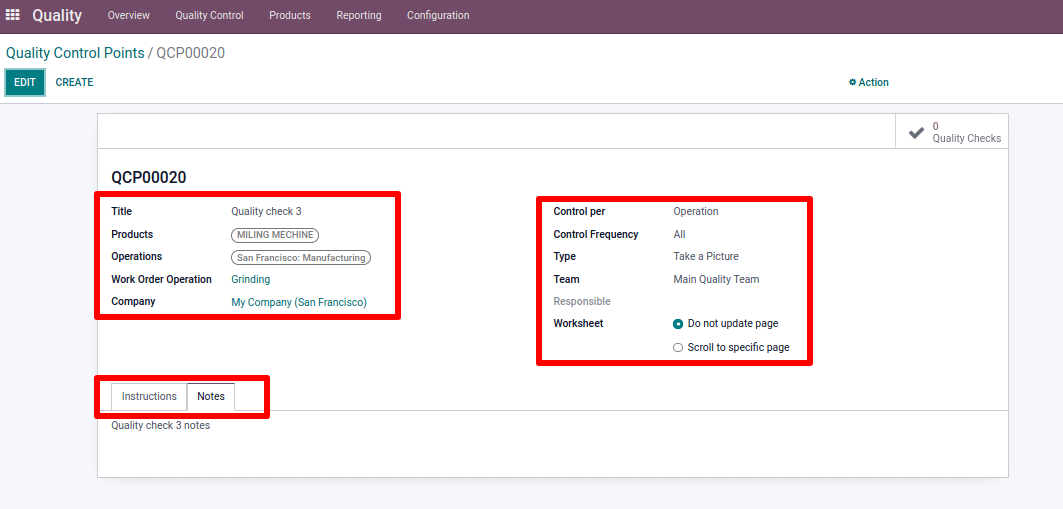

:Quality Control > Control Points

It is possible to develop quality checks for both the final product and the procedures. There are various types of quality checks, such as pass/fail, take a picture, measure, and so on.

On the basis of measurement, Quality check 1 is included for the first operation. We can include quality instructions, a failure message, and some additional information.

Quality check 2 is for the second operation, which is either a pass or a fail. We can include quality instructions, a failure message, and some additional information

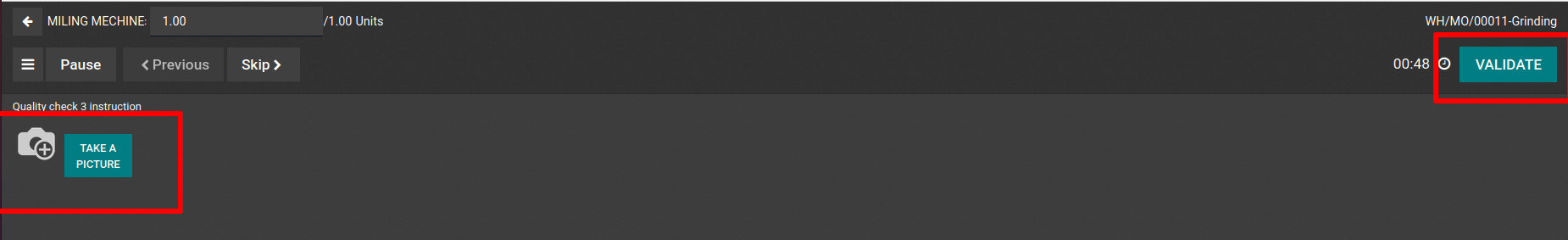

Quality check 3 is for the final operation, which is to upload a photo of the finished product. We can include quality instructions and some additional information.

Manufacturing Order

The next step after generating a bill of materials in manufacturing is to produce a manufacturing order.

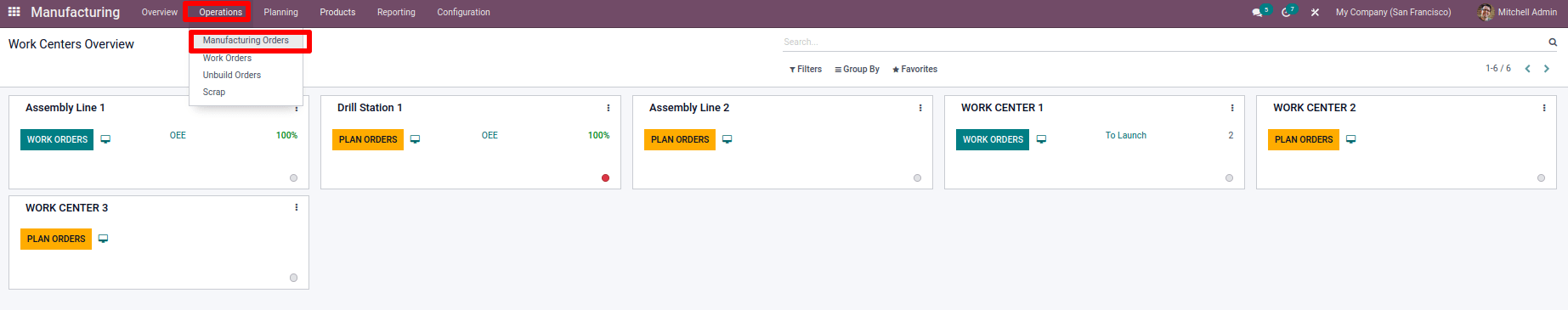

To do so, go to the Operations tab and pick the manufacturing order.

Go to Operations > Manufacturing Order

Then click on Create Button

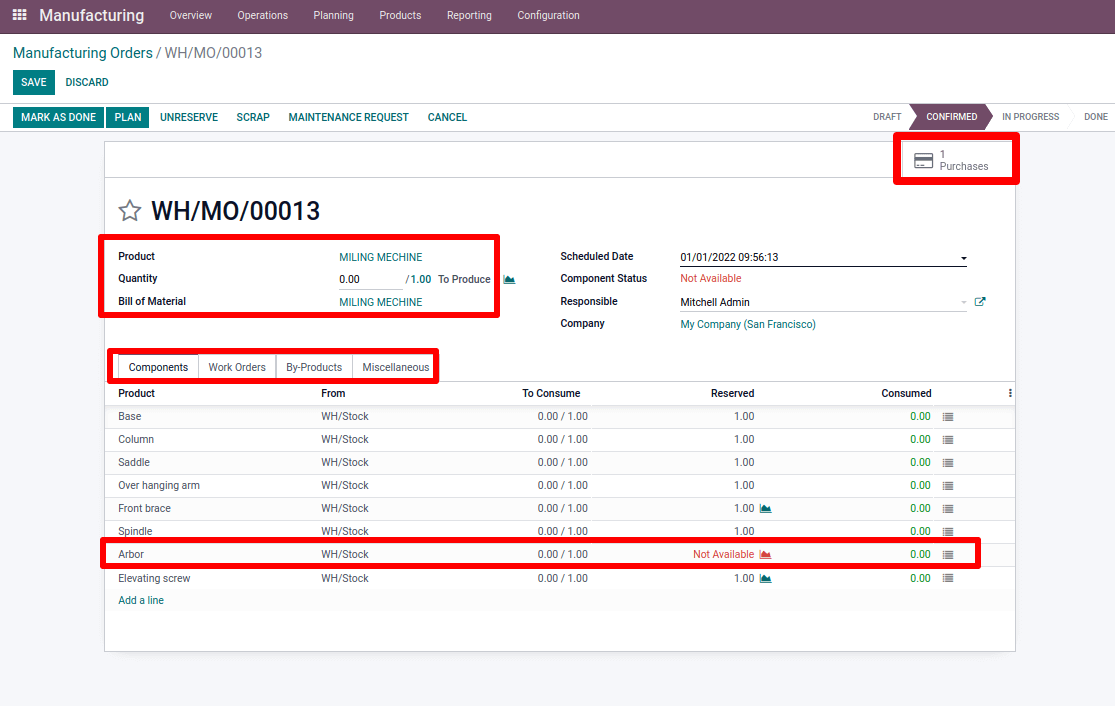

Add the product name and bill of materials to generate a manufacturing order. The components and operations listed in the bill of material are then added automatically.

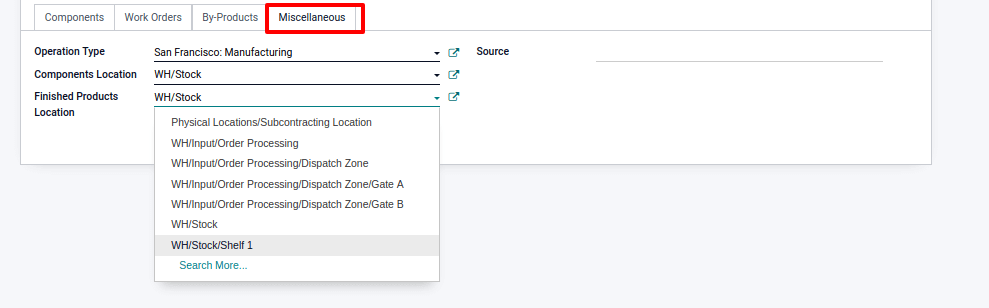

It is mentioned in its operation type in the miscellaneous tab and the place chosen for product storage is the same as that specified in the operation type. It can also change the location of the destination by selecting from the dropdown list.

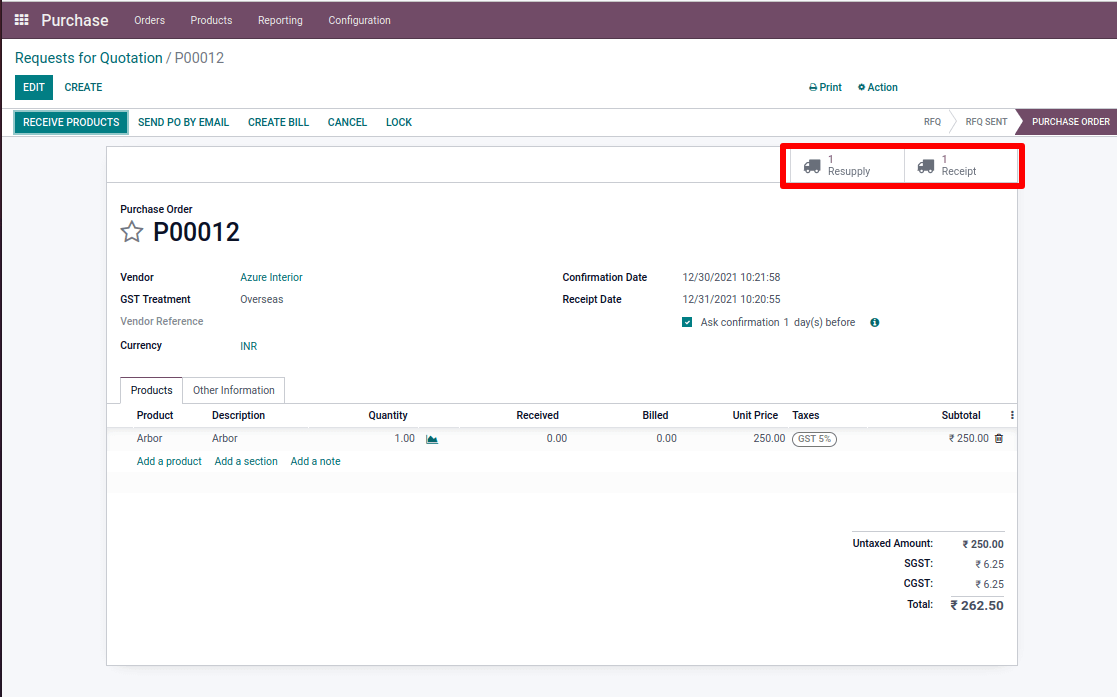

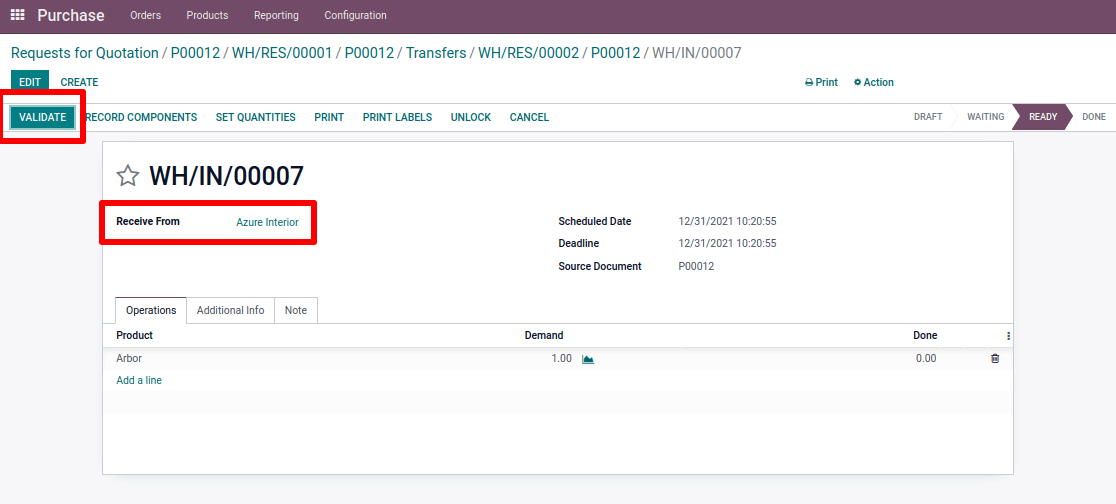

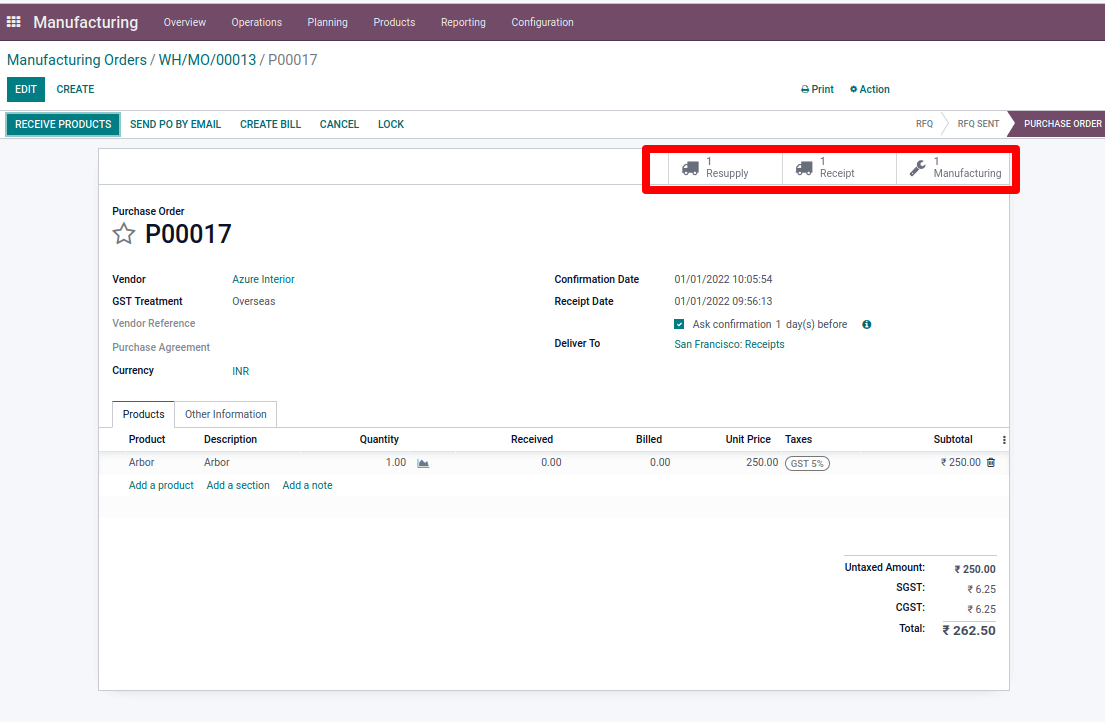

A component ‘Arbor’ is unavailable. After confirming the order, a purchase order is created for Arbor, which can be viewed in the smart tab. Open and confirm the purchase RFQ.

Because we need to provide components to the subcontractor first, resupply and a receipt are established in the smart tab.

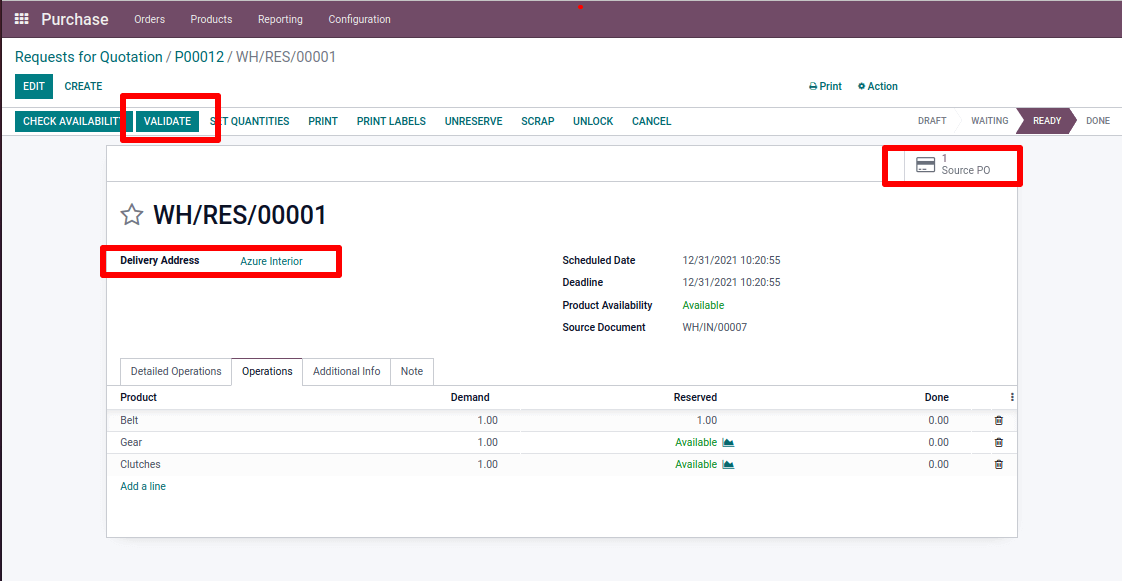

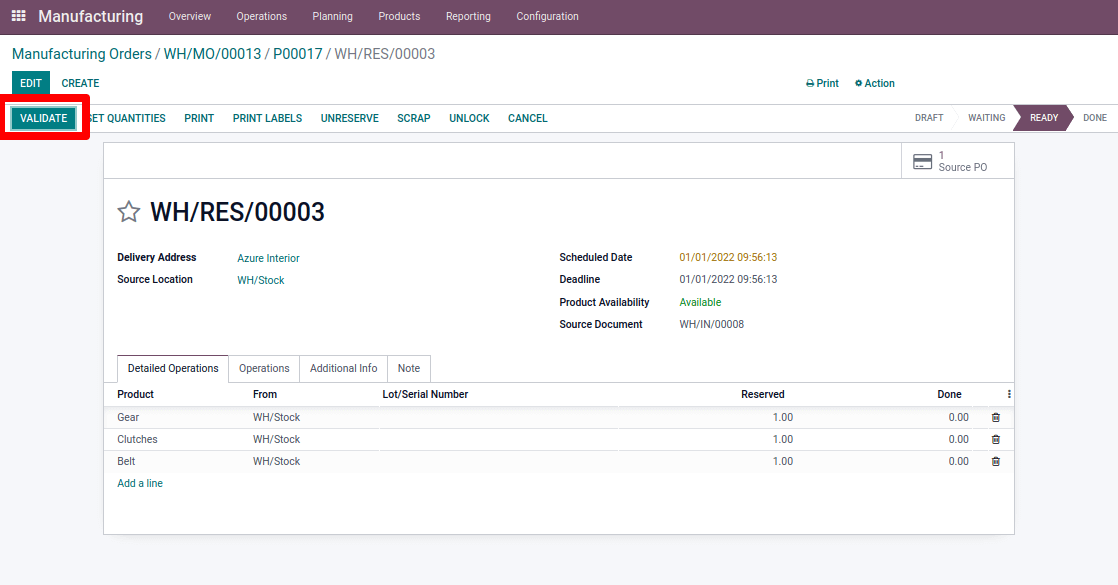

Now validate the resupply. Thus the product which is required to manufacture the main product has to be supplied to the vendor.

Once the finished products are sent over by the vendor or the subcontractor you should receive the product.

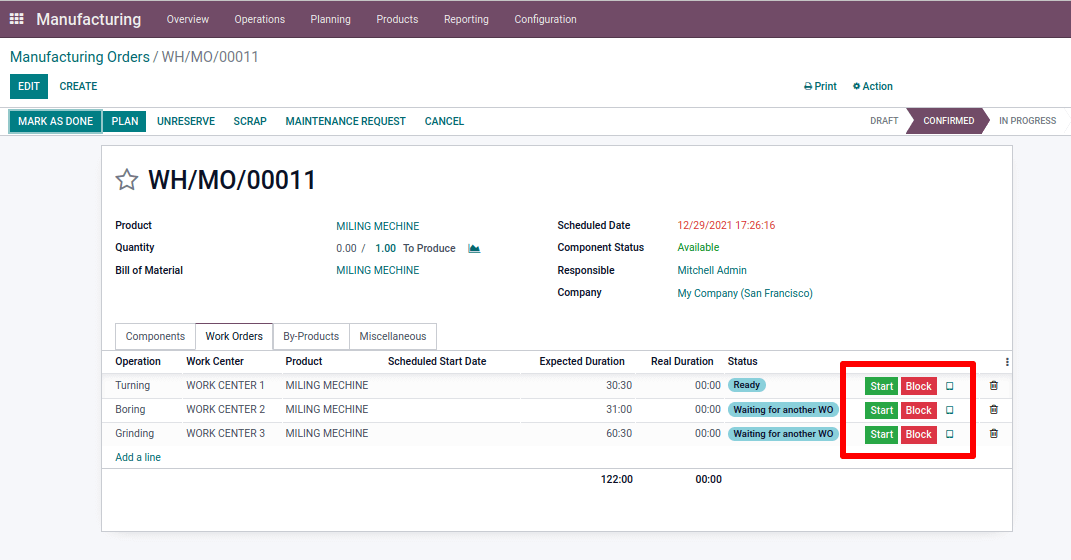

The manufacturing order is then ready to be fulfilled. By pressing the start button, we may begin the operation. Moreover, there is also a mobile view that can be access through remove devices proving you with complete operational control to the operations of the manufacturing operations even remotely.

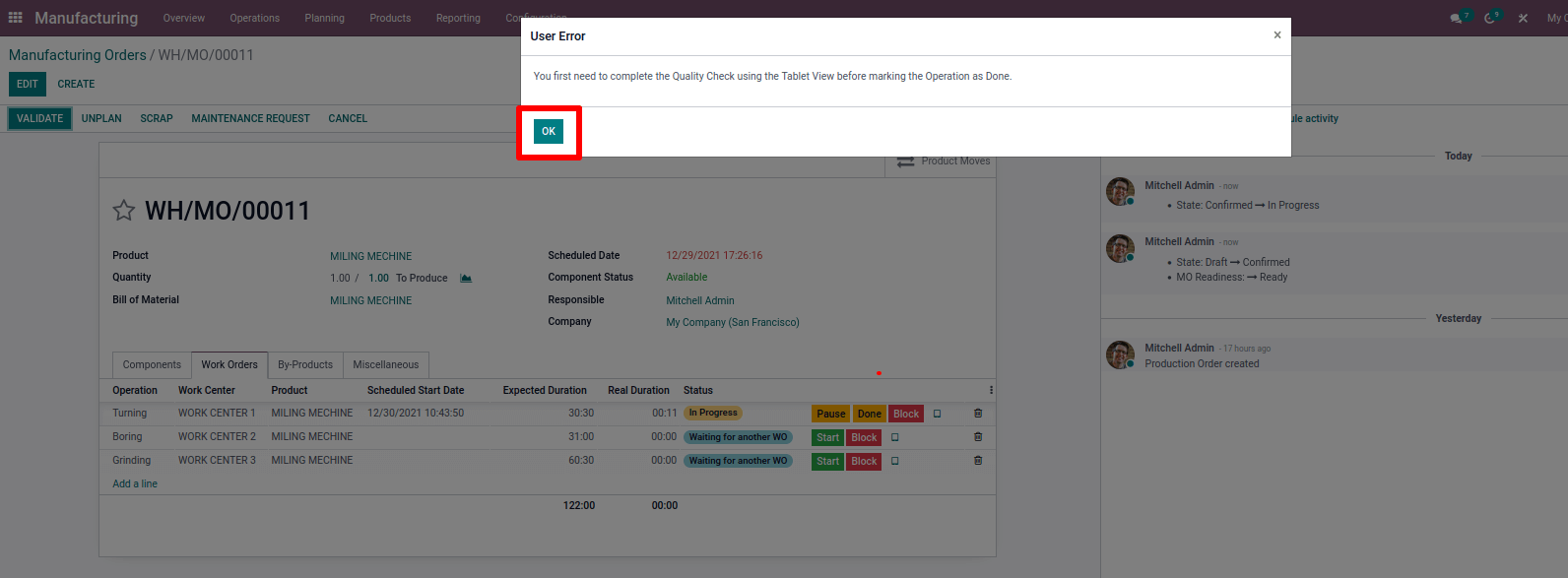

Before we finish the process, we must double-check the quality that we added before. When we try to terminate the procedure before the quality check, a popup notification appears as depicted in the following screenshot.

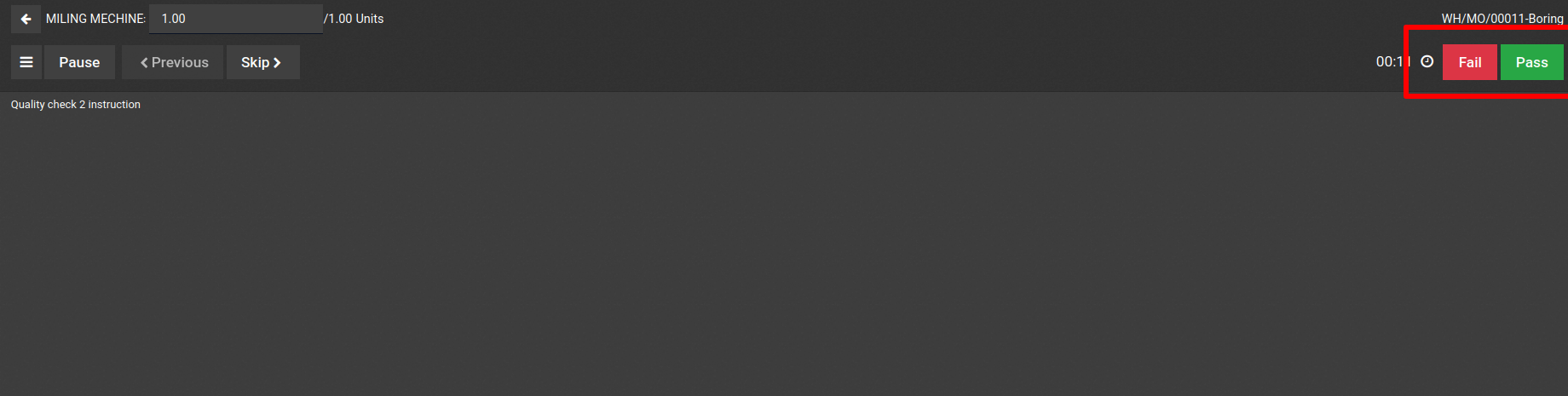

We added a quality check measure and added measurement to the initial operation. After testing quality, we can execute the second operation as pass or fail.

Third, take a picture of the product and validate it.

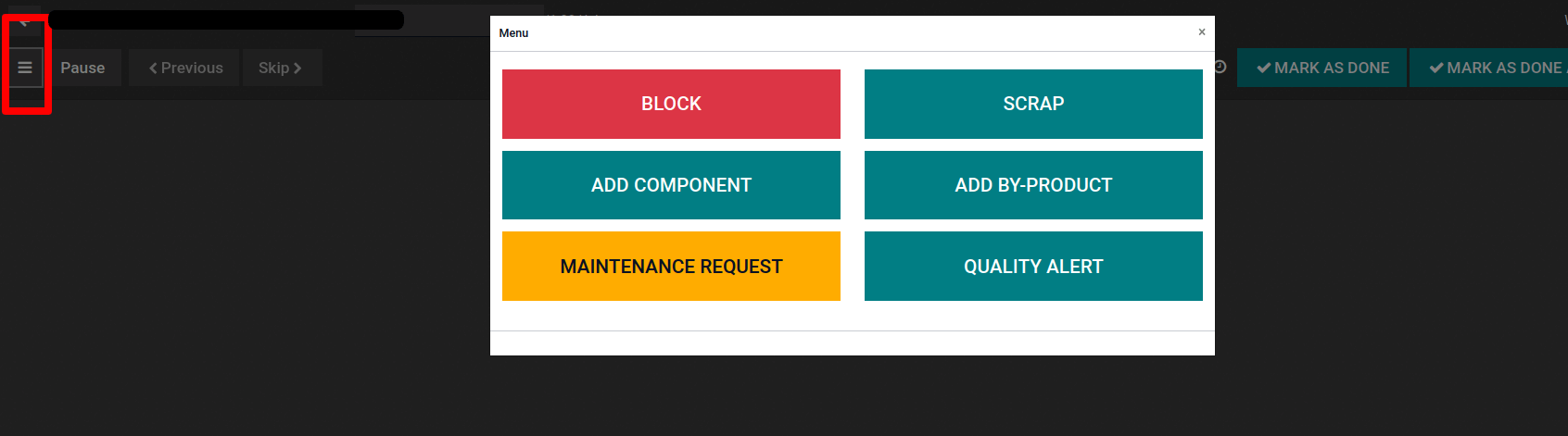

There is also a mobile view where we can add a lot of things. Bolt was added as a byproduct and a maintenance request from there.

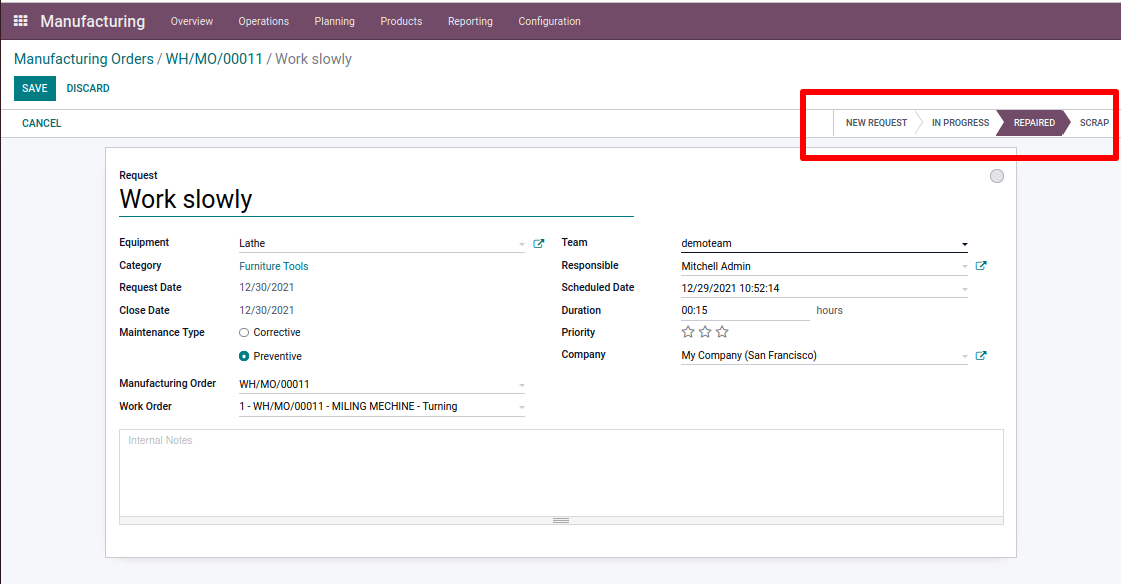

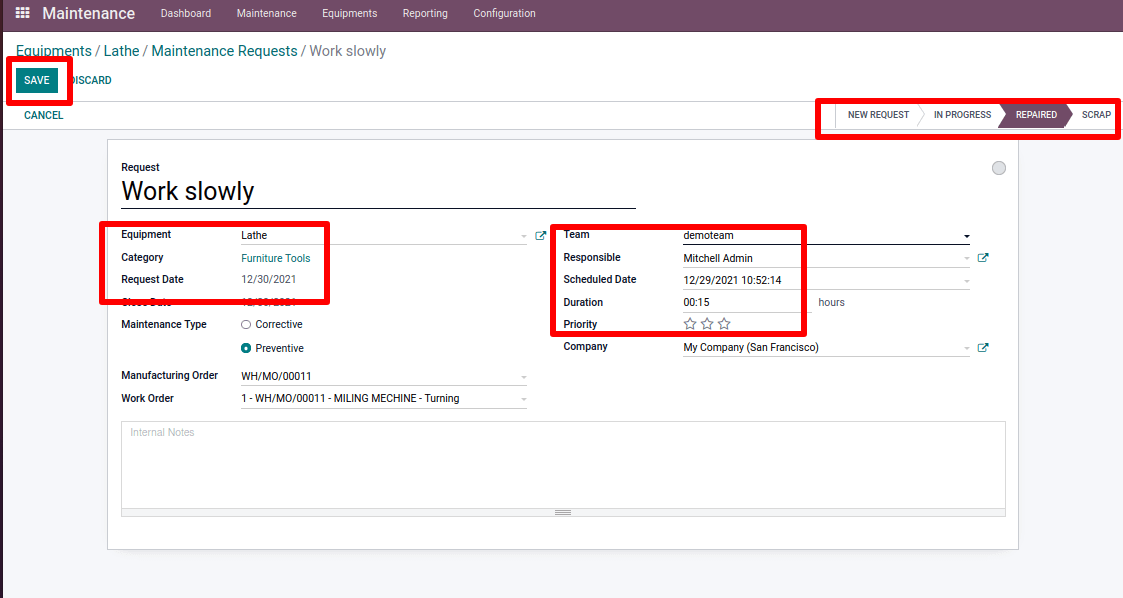

It’s possible to change the stages of maintenance order from New Request to Repaired, or scrap the Equipment.

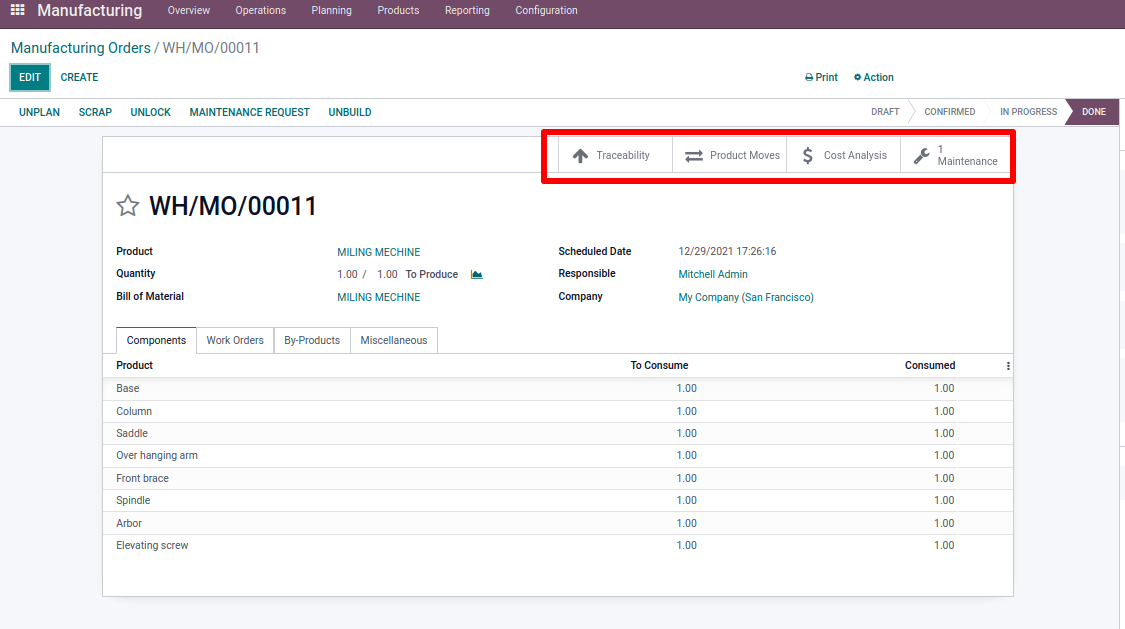

After that, we can mark the order as completed by clicking Mark as Done. We can collect product movement, traceability, cost analysis, and the created maintenance request through the smart tab.

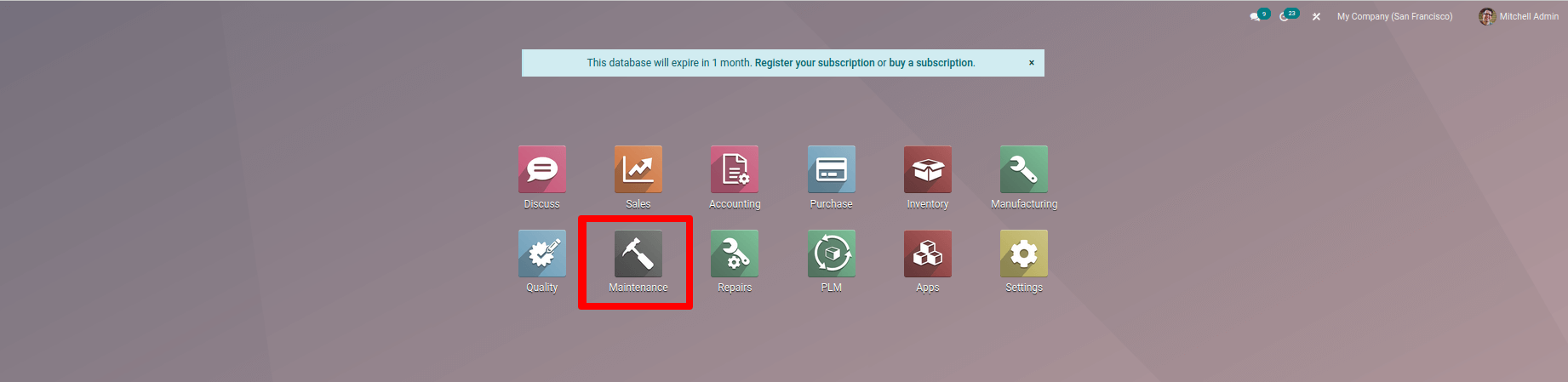

Maintenance

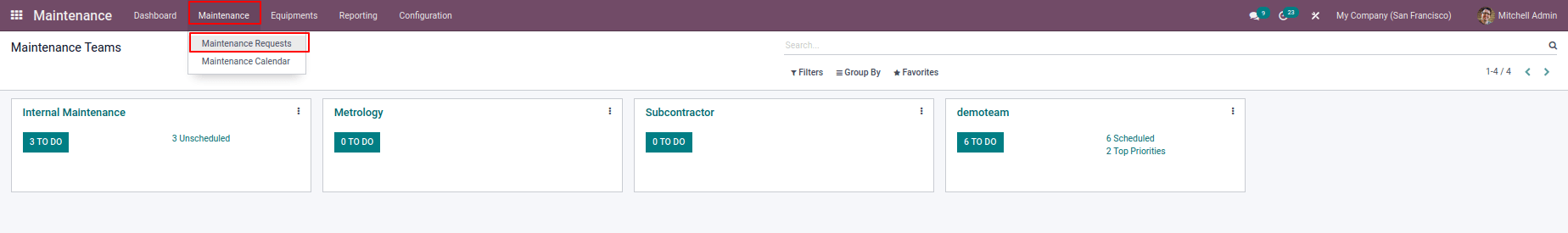

Maintaining used equipment is an important aspect of the manufacturing process. We can properly maintain our equipment with the help of the Odoo maintenance module. It is possible to add a maintenance request from a manufacturing order, as we discussed earlier. We can alternatively perform this from a different module called Maintenance.

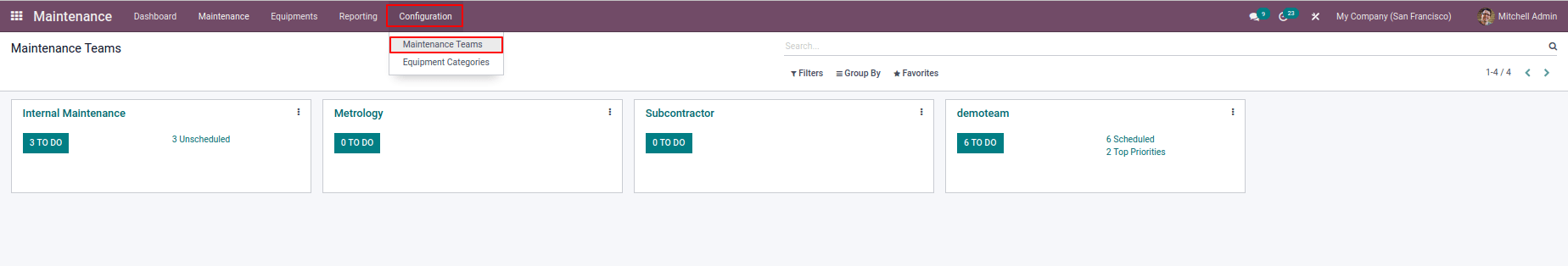

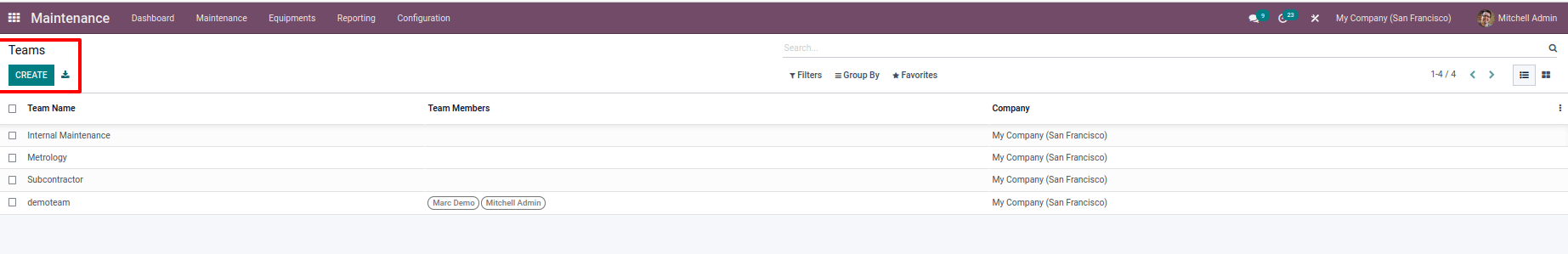

We can select the maintenance team under the configuration tab.

By hitting the create button, we can form a new team.

: Configuration > Maintenance Team

After that, save it with the names of the team members and the name of the team

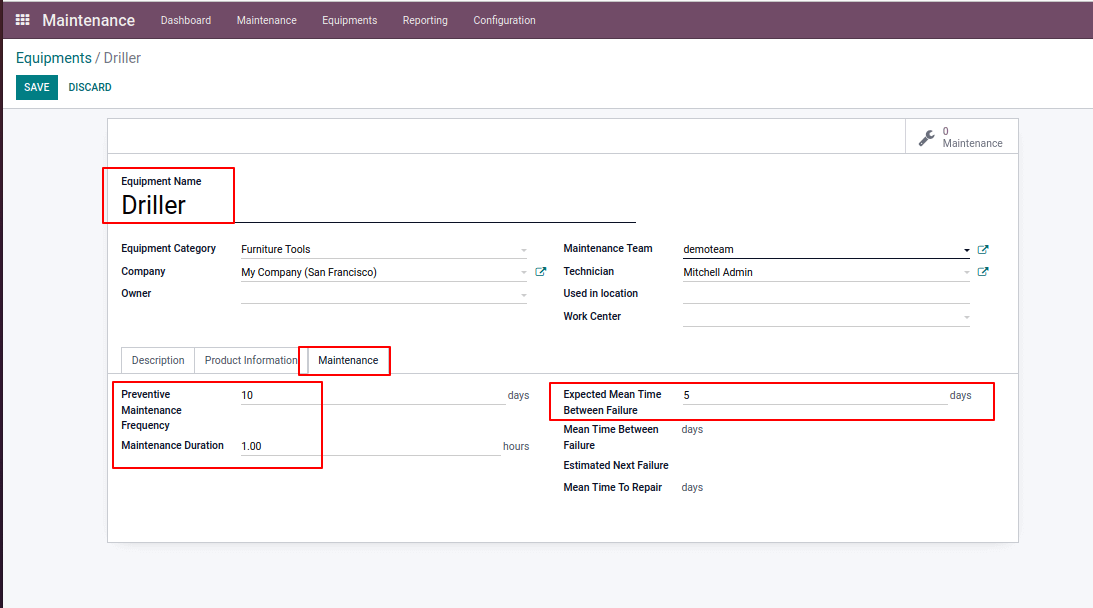

We can see all of the equipment by selecting machines and tools from the equipment menu.

: Equipment> Machines and Tools

We can see the cost of an item under the product information page, as well as the effective date, which is the day the item became operational. With this information, we can determine the mean time between failures using this effective date.

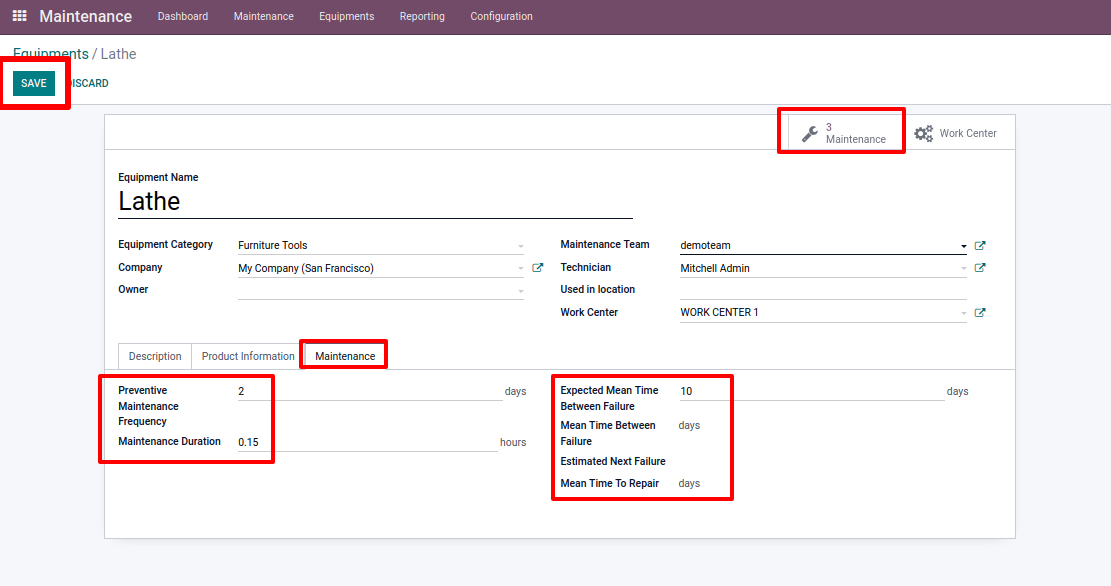

We can set Preventive Maintenance Frequency under the maintenance tab, which is the number of days between preventive maintenance, Maintenance Duration i.e. the time spent on the maintenance procedure.

Mean Time Between Failures Expected (MTBF)

Then create a maintenance request. We get maintenance requests in the maintenance tab, and we can create new ones from there.

We can make a request by providing equipment information. There are two categories of requests for maintenance. The first is corrective, while the second is preventive. Preventive maintenance is performed at regular intervals, whereas corrective maintenance is performed only when the equipment is not in working order. Preventive maintenance assists us in avoiding unanticipated failure.

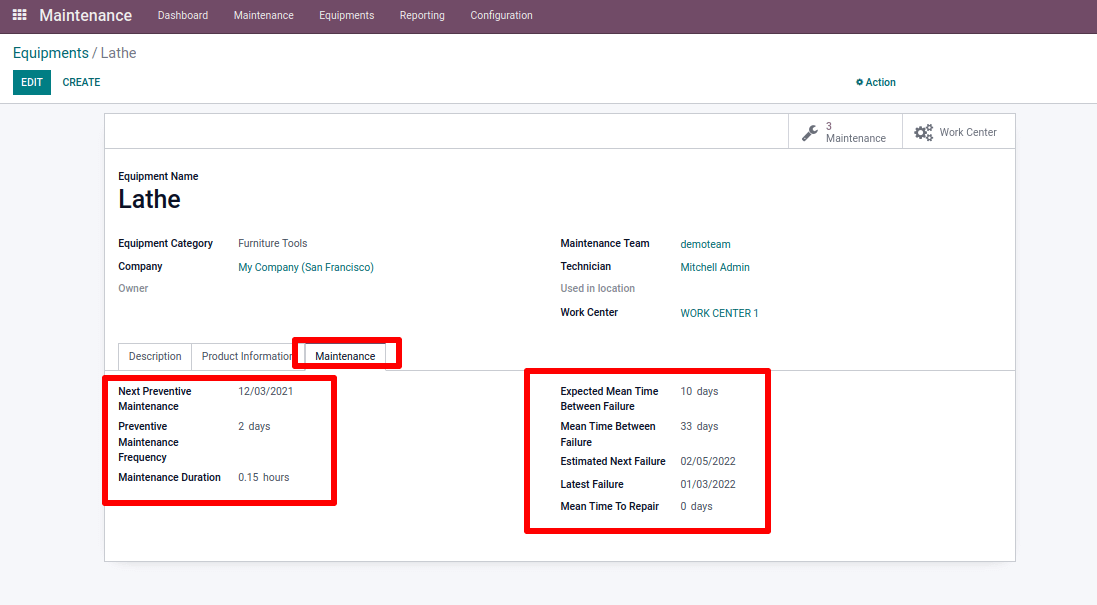

After first being repaired while checking the maintenance tab on our equipment. The following items have been updated: Next Preventive Maintenance, Mean Time Between Failures, Estimated Next Failure.

The sum of the most Latest failure and the mean time between failures is the estimated next failure. The sum of the effective date and the preventive maintenance frequency is the next preventive maintenance. The most recent failure is the failure date that happened recently for the equipment.

Estimated next failure = latest failure +mean time between failure

Next preventive maintenance = effective date + preventive maintenance

Frequency

The MTBF, MTTR, and Estimate next failure is updated in the work center’s equipment tab.

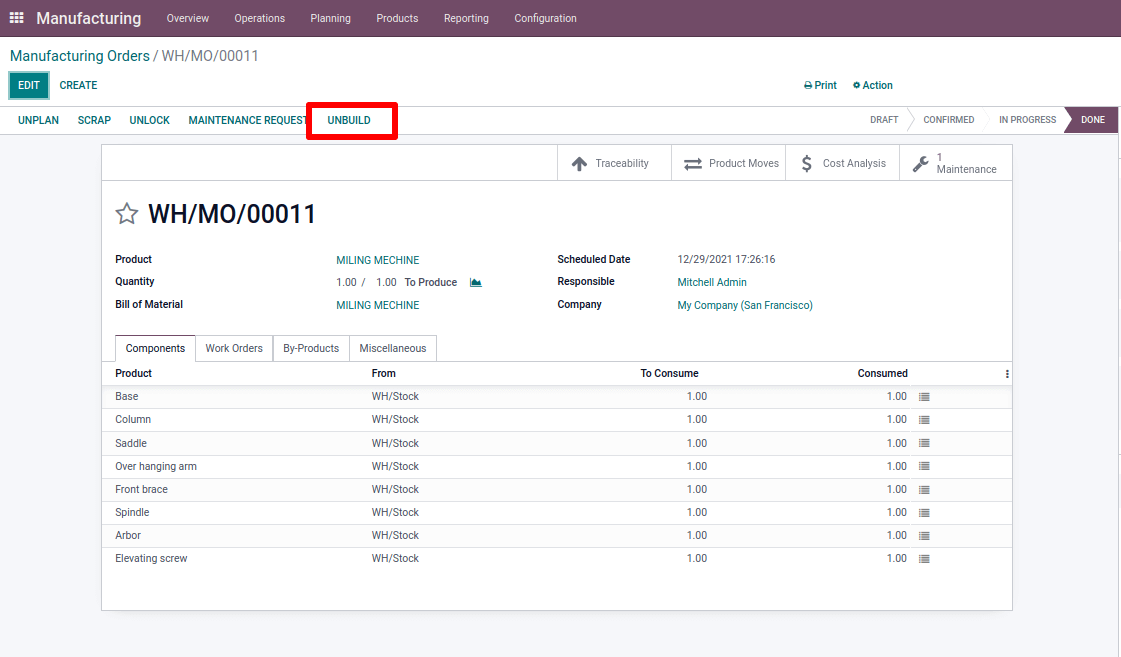

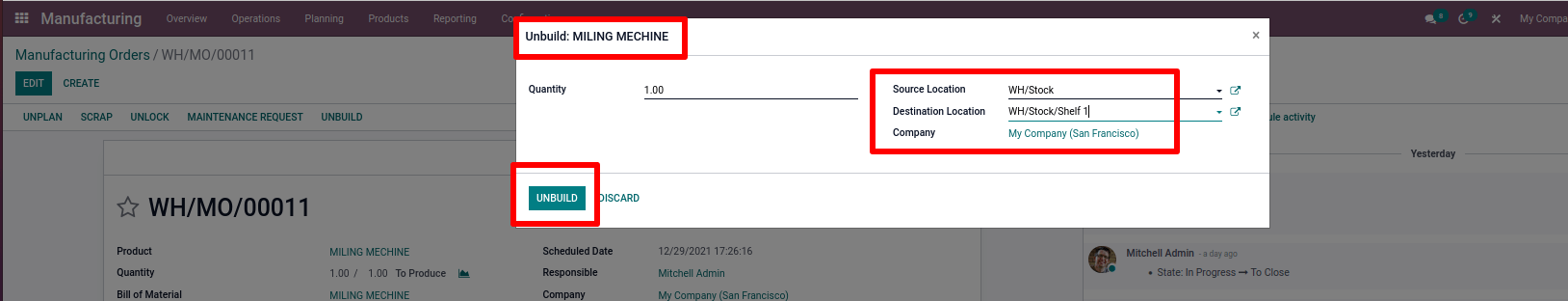

Unbuild

We can deconstruct the products that are manufactured. To do so, select the unbuild option.

We can specify where components should be taken. Then select the option to unbuild.

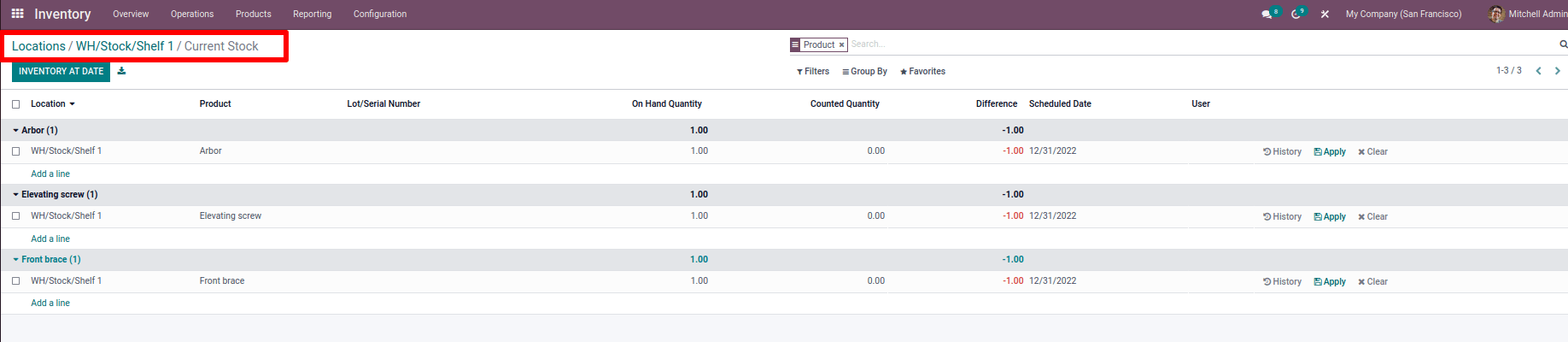

When we check the current stock of the destination location from the inventory module, the stock is updated.

PLM ( Product Lifecycle Management )

We can track the lifecycle of our product using this Product Recycling Management. It assists us in maintaining a high standard of quality and improves production efficiency.

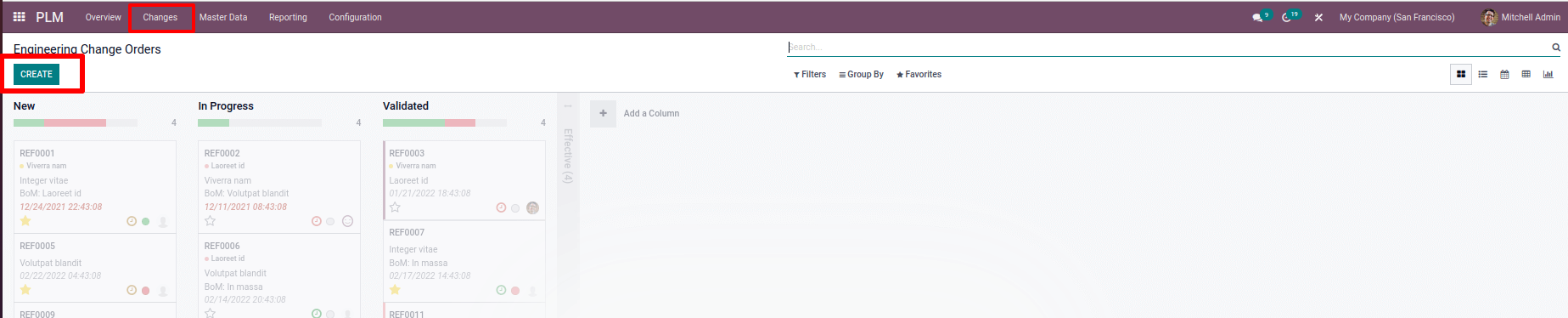

To make new adjustments or a new design to an existing product, click on changes to acquire an Engineering Change Order. From here, we can see a list of new and past adjustments we’ve made. There is information on the altered components and so on.

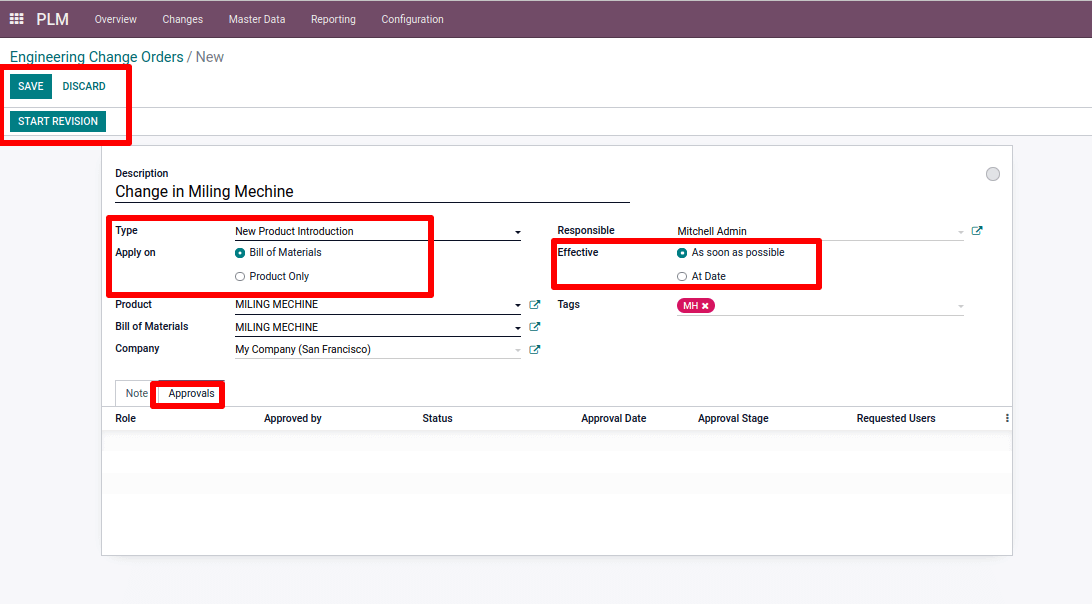

Click the Create button, enter a description, select the type of change, and click Apply.

It can be used on the bill of materials or in the product. Add the name of the product that will be affected by the change order. There are two effective methods: the change can be implemented as quickly as possible, or the change can be implemented on a specific date.

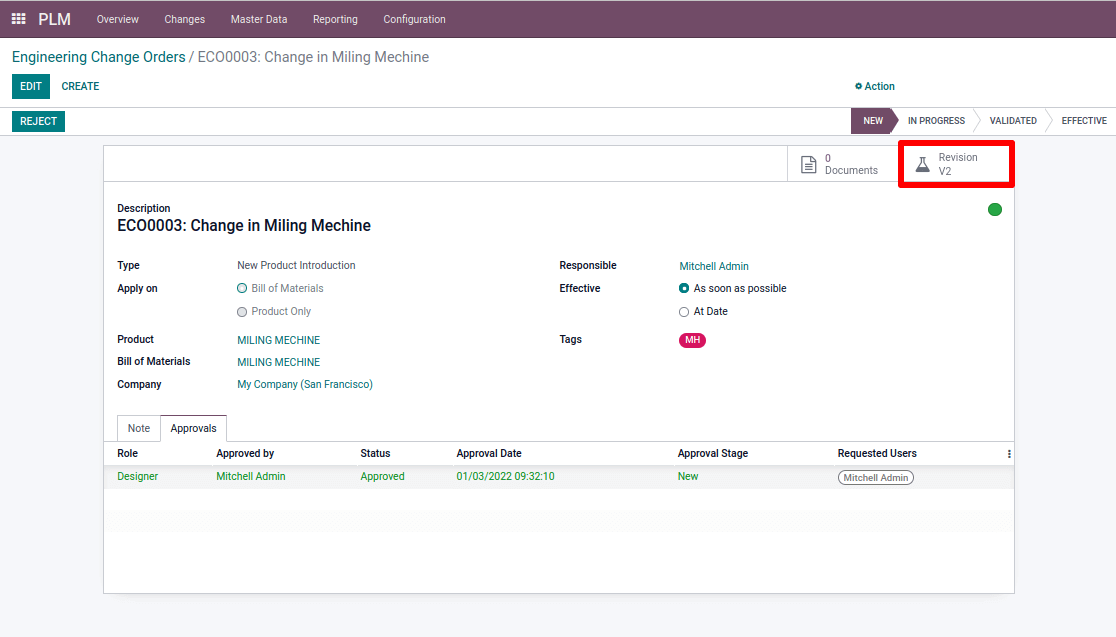

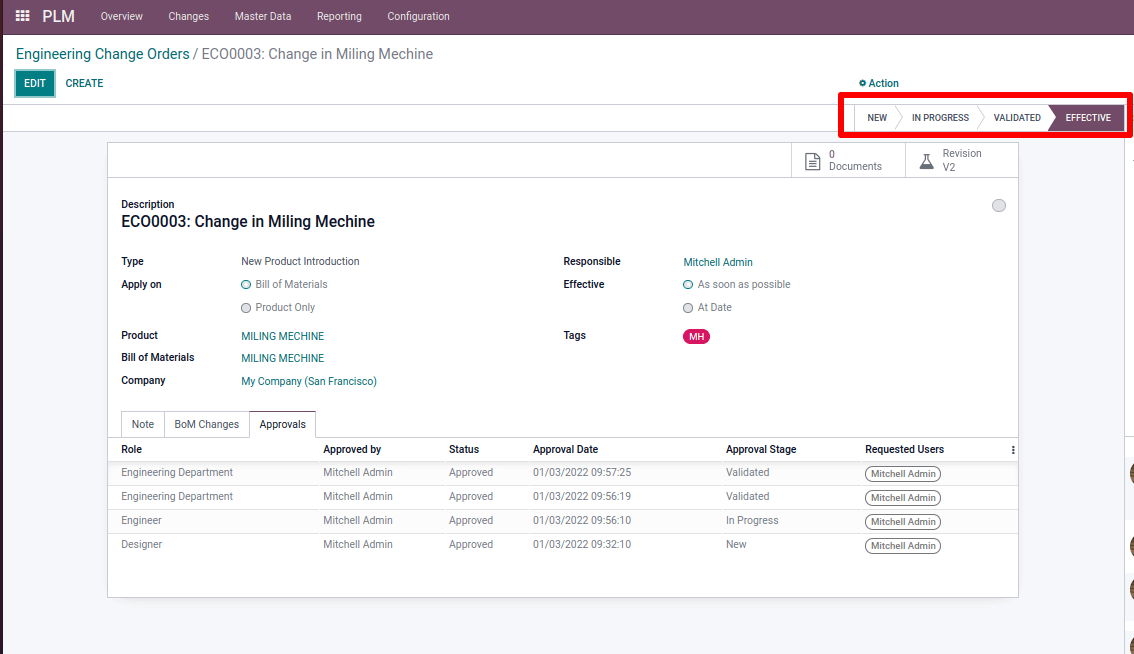

Save your work and start revision. We can see the approve or reject button. When we check the approval tab, as well as the approval made by the person in the given role. They have the option to approve or reject the change in these roles, which are assigned in stages. Revision V2 is an option in the smart tab.

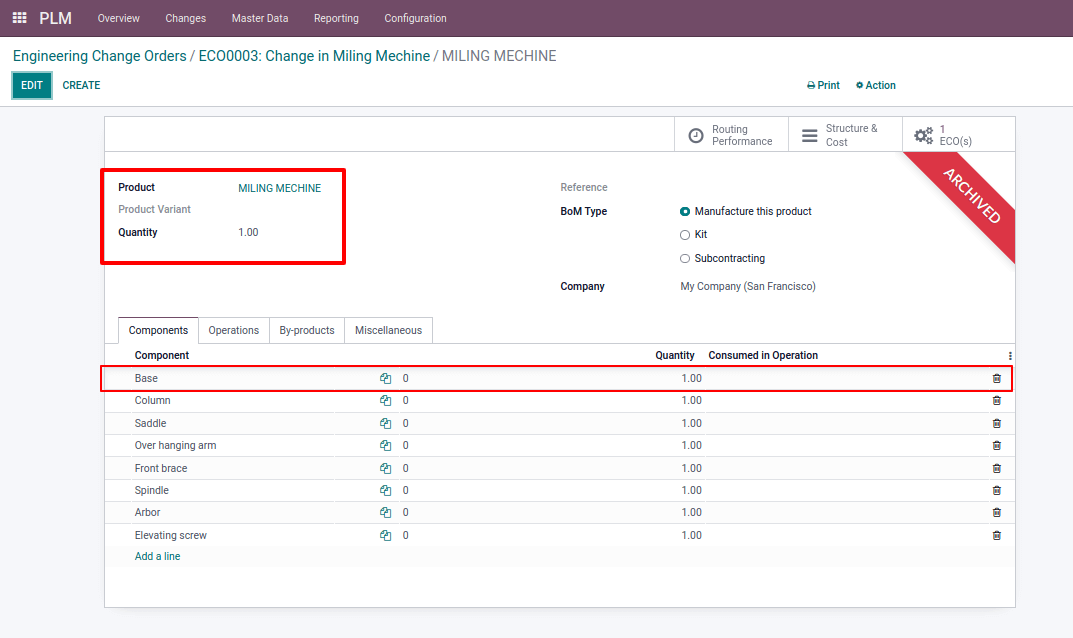

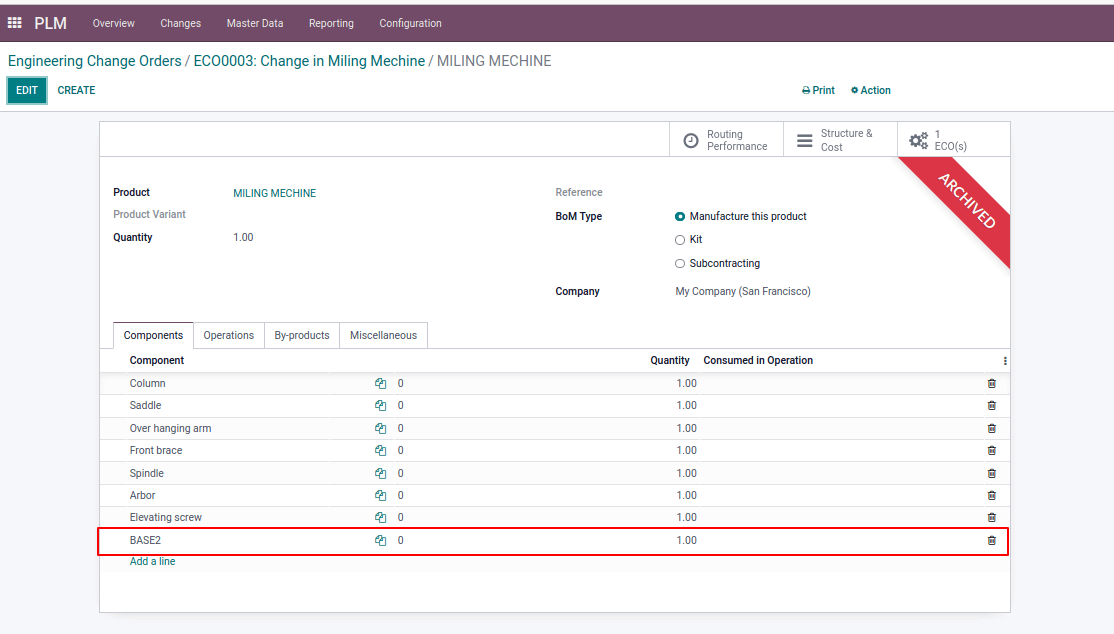

Because we picked apply on a bill of material in ECO, we can see the product’s bill of material while picking this. We can alter components from here.

To improve our product, we are removing the component Base and replacing it with BASE 2.

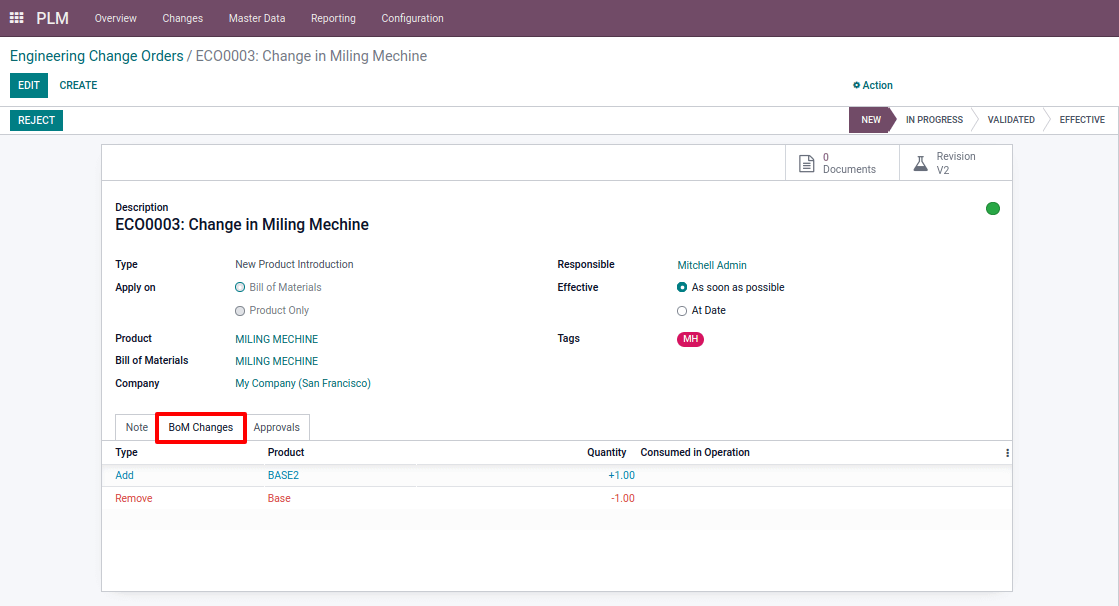

Returning to ECO after saving this, we can see an additional tab named BoM Changes has been created with the specifics of the changes we made.

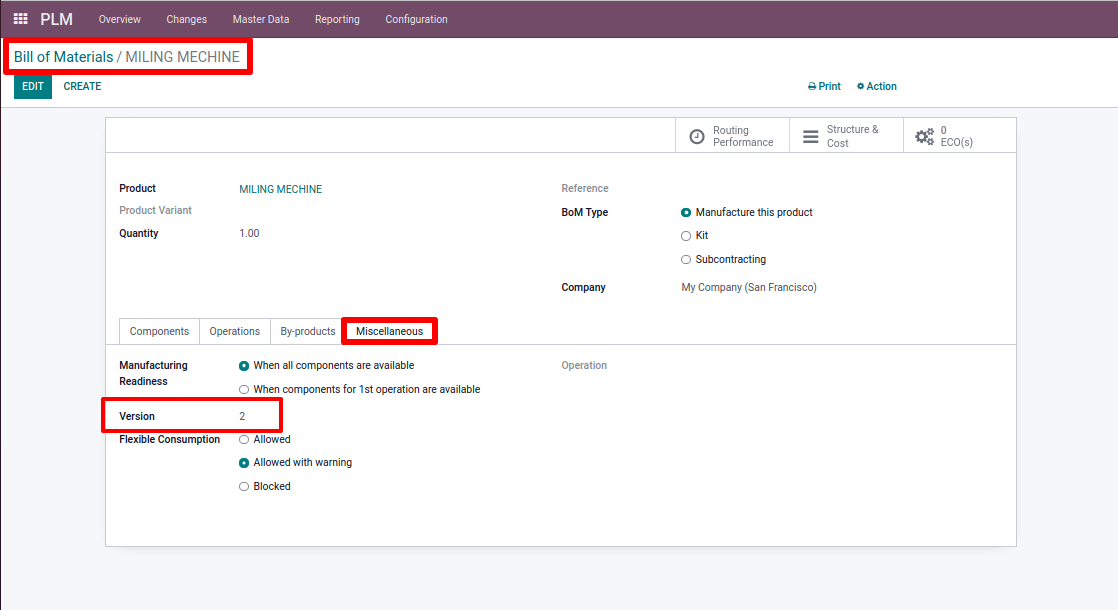

The stage shifts to effective after all changes have been made and all approvals have been received. After that, the version of the bill of materials was modified to version 2.

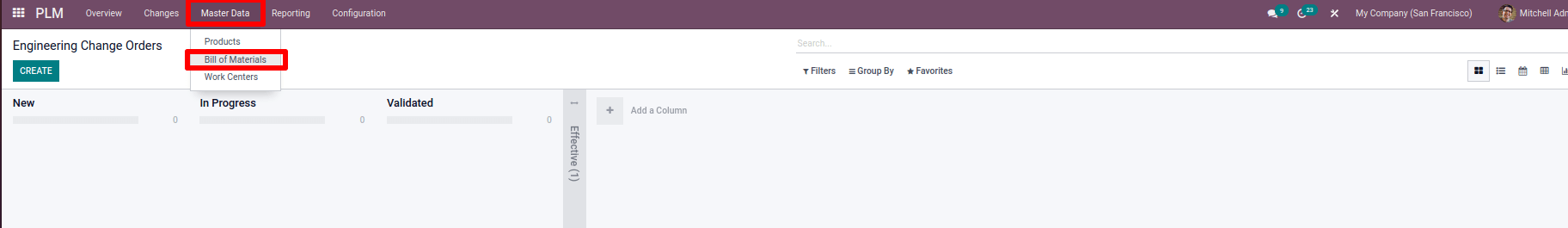

To double-check this Bill of Materials from Master DataT.hen look at the product’s bill of materials.

: Master Data > Bill of Material

The version number has been updated in the Miscellaneous tab.

Using ECO in PLM, it is also possible to make modifications to the product.

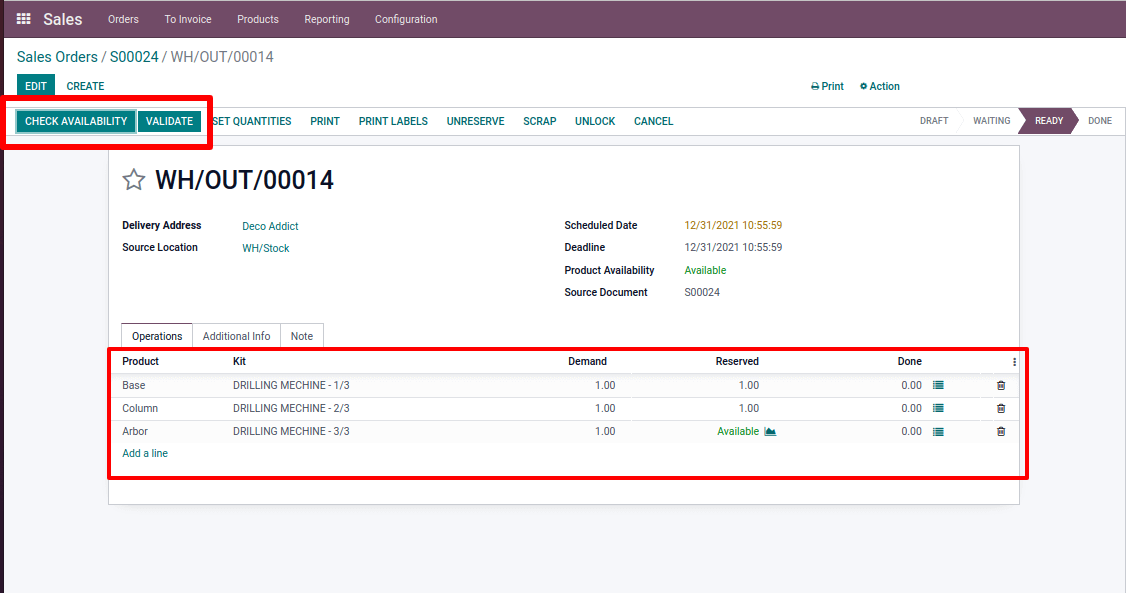

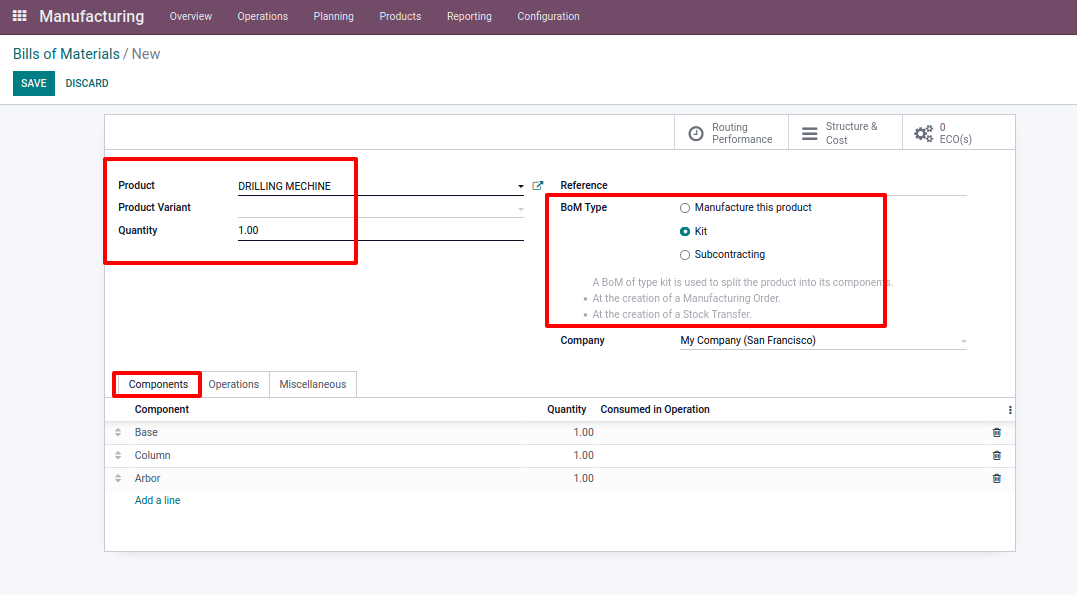

Bill of type: Kit

Bill Type Kit, allows you to sell multiple products at once while still being treated like one. When we sell a computer, for example, we must also sell the mouse, keyboard, and other accessories. In this situation, all of these products are treated as a single unit.

In various manufacturers, including machines, there may be an opportunity to set up the machine at the customer’s location. In such cases, we must transport all components to that specific site, yet it is treated as a single unit. The third bill of material type kit can be used here.

Create a bill of materials for the kit type of product. components must be added. The bill will then be saved and confirmed.

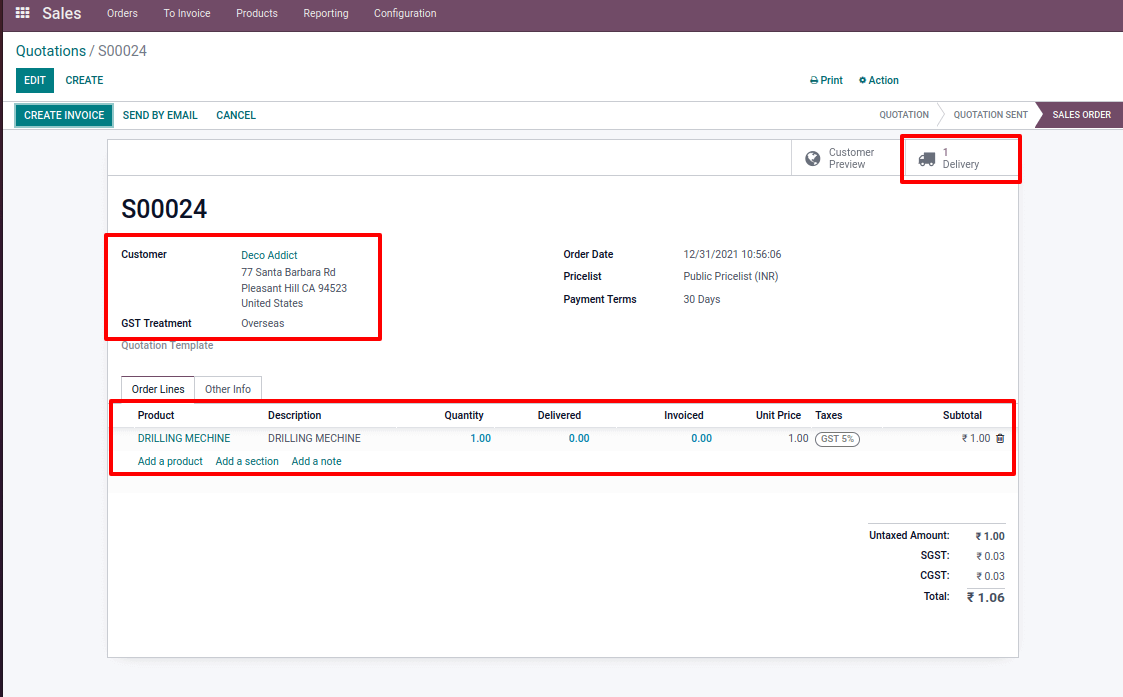

We can then sell the product and establish a sales order. In the order line, add the same product. The order should be saved and confirmed. Then, on the smart tab, a delivery is created.

We can observe that the product components are added to it automatically. We can keep track of the delivery and confirm it. In regards all of the components and the finished product to be one product, but it has different inventory movements.