For a firm to succeed, offering consumers the finest service possible is essential. Planning every action is implied, including manufacturing orders, deliveries, receptions, and so forth. You must appropriately configure lead time and coordinate scheduled dates in order to achieve this.

Odoo offers commitment dates, or end dates, for each process by employing lead times.

This is the day that your customers will receive the things he bought, as in a sales order. The commitment date is significant from the perspective of the customers since it provides an estimate of when they will get their orders. The dates account for all other lead periods, including those associated with manufacture, shipping, or suppliers.

There are different lead times, each is determined using different indicators.

Customer Lead Time: This is the time frame that you specify as the default. So, today plus the customer lead time is the anticipated date on the sales orders.

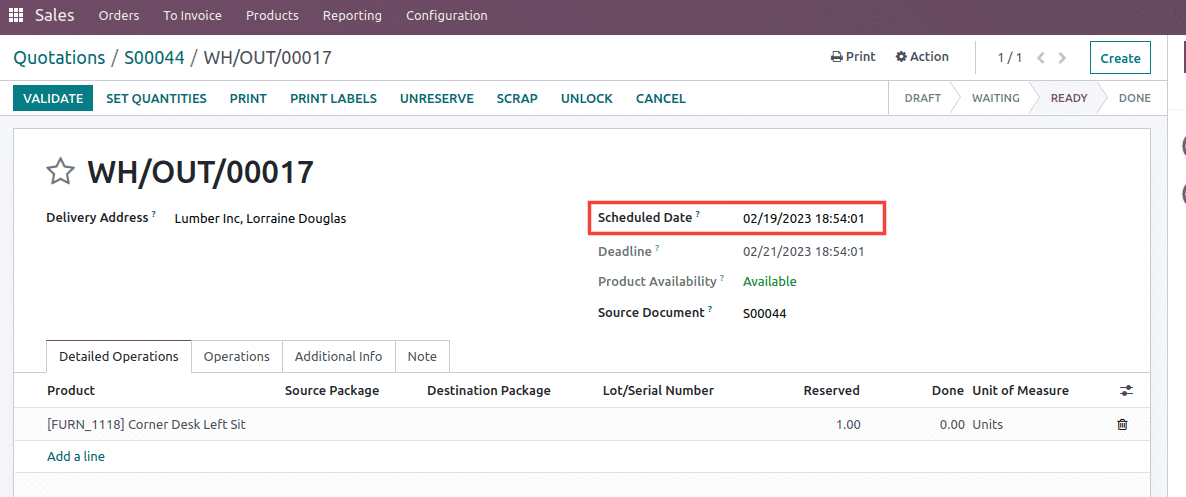

Sales Security Lead Time: The idea is to be prepared for shipment a few days before the customer’s genuine commitment is made. The delivery order’s default scheduled date is then the SO delivery date less the security lead time.

Purchase Security Lead Time: To account for unforeseen vendor delays, the system will produce Purchase Orders for product procurement that are many days earlier than intended.

Purchase Delivery Lead Time: This refers to the expected period of time between the confirmation of a PO and the delivery of the requested goods. The default PO Order By date is the Receipt planned date – Vendor delivery date.

Days to Purchase: The time it takes the purchasing department to verify a purchase order. Odoo adds the line to the existing RFQ rather than establishing a new one if a different RFQ to the same vendor has already been opened. The precise date is then written on the line.

Manufacturing Lead Time: This refers to the expected amount of time needed to create a product. This lead time does not account for the routing time and is independent of the quantity to be produced.

Manufacturing Security Lead Time: Extra time to reduce the possibility of a manufacturing delay.

Sales Lead Time

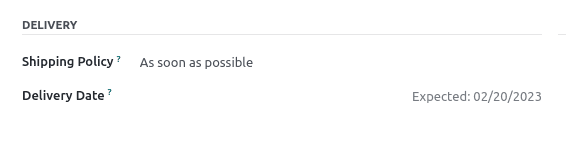

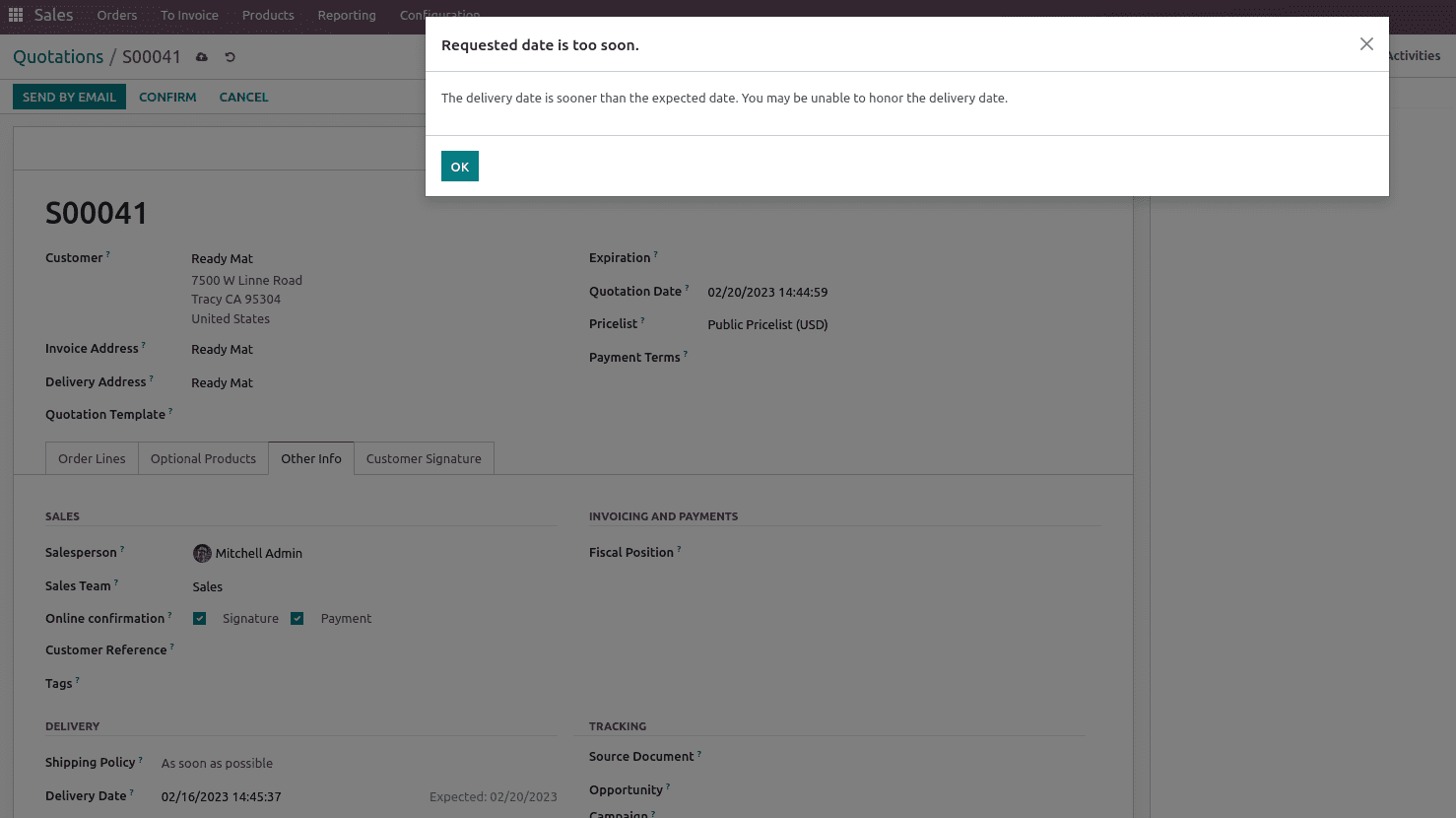

The sales module has the option to mention the Delivery Date which permits viewing the Expected Date field, an additional field on the sales orders. This one is automatically calculated using the various lead times that were previously defined as shown in the below screenshot.

Here if the delivery date is scheduled before the expected date then a warning message comes which tells that the delivery date is sooner than the expected date. You may be unable to honor the delivery date.

Customer Lead Time

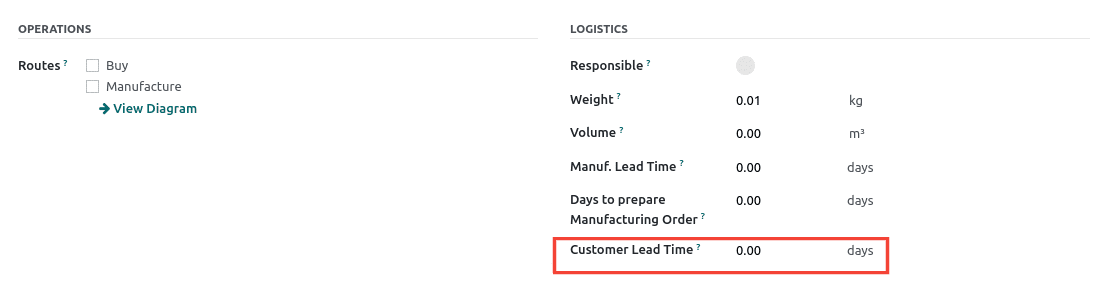

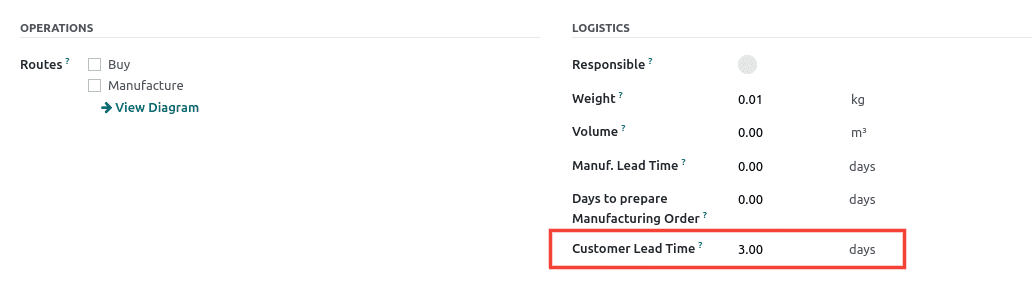

The Customer Lead Time is the minimal amount of time from the time a sales order is entered until the product is prepared for shipping. It is configured separately for each product by going to Sales ? Products and under inventory page one can set the customer lead time.

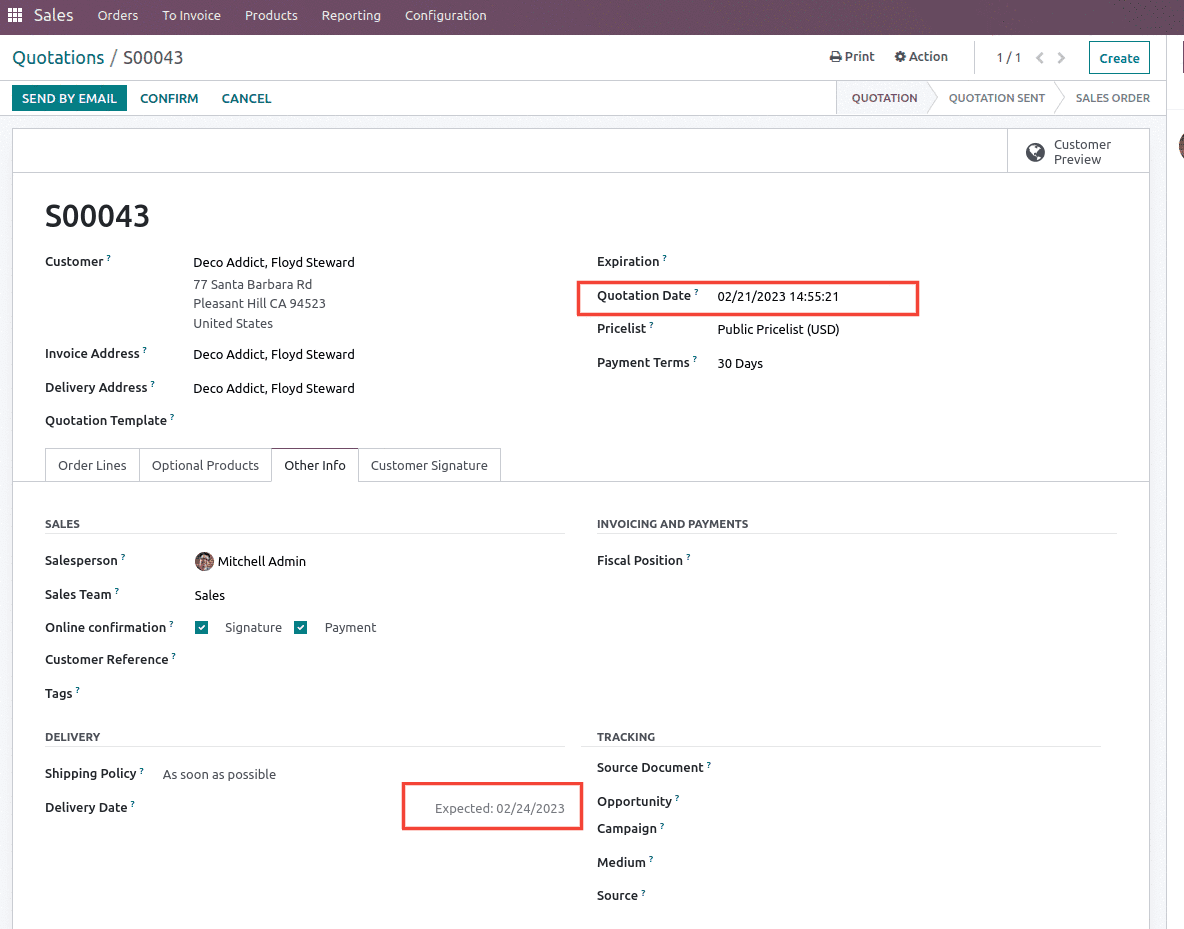

For instance, a customer orders product Acoustic Bloc Screens on Feb 21st, but the customer lead time is three days. In such a situation, the order is expected to leave the building on Feb 24th as shown below.

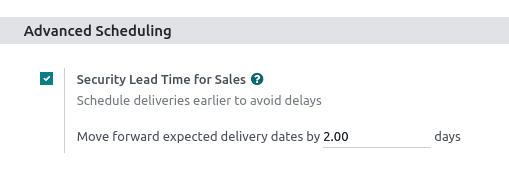

Security Lead Time for Sales

Security Lead Time for Sales is a parameter in the Sales module that adds extra days to the expected delivery date to account for potential delays and ensure that the customer receives their item on time. To enable the feature go to Inventory > Configuration > Settings and, at the bottom, turn on the Security Lead Time for Sales function under Advanced Scheduling.

As an example, if an order is expected on Feb 21th, but the security lead time is two days.

In that instance, the delivery order is expected to arrive on Feb 19th as shown in the below screenshot.

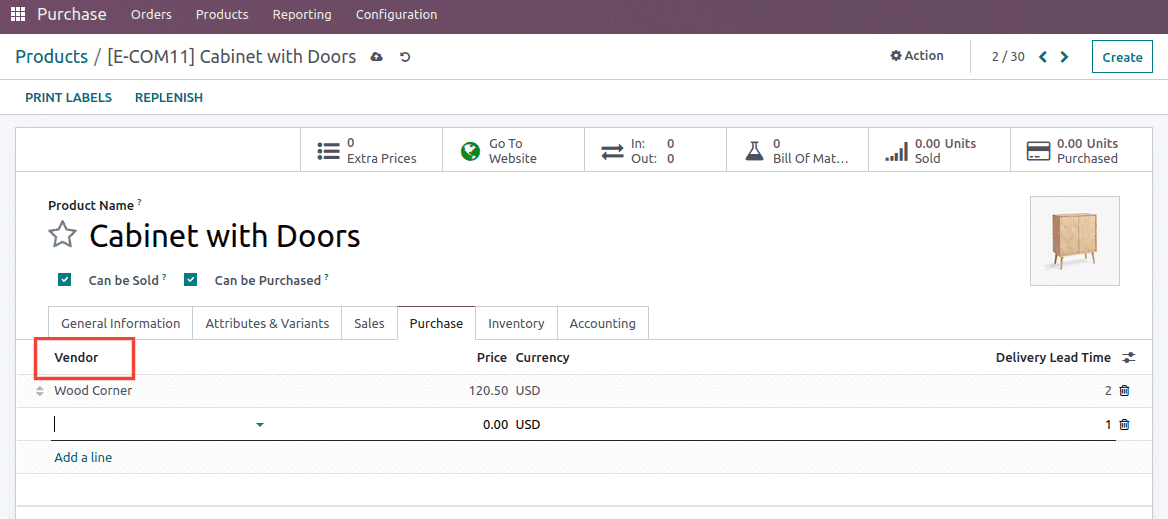

Vendor Lead time

Vendor lead time is the same as the purchase lead time and it refers to the amount of time required for a product you ordered to be delivered to you is known as the vendor lead time. It is configured at the product level where one can set the vendors under the purchase page of the product.

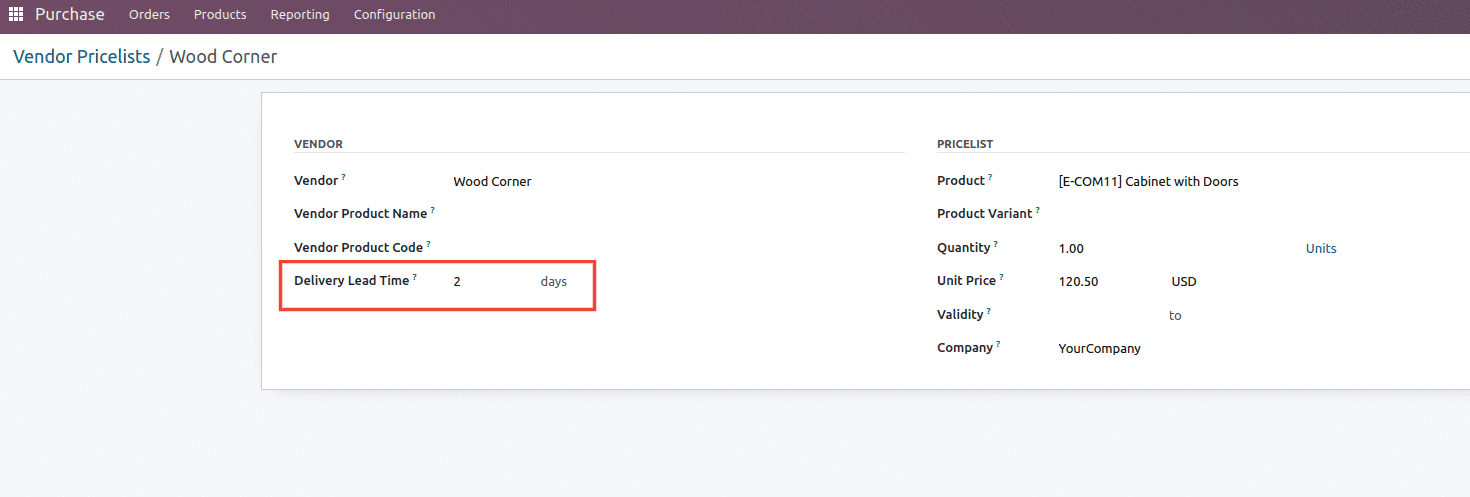

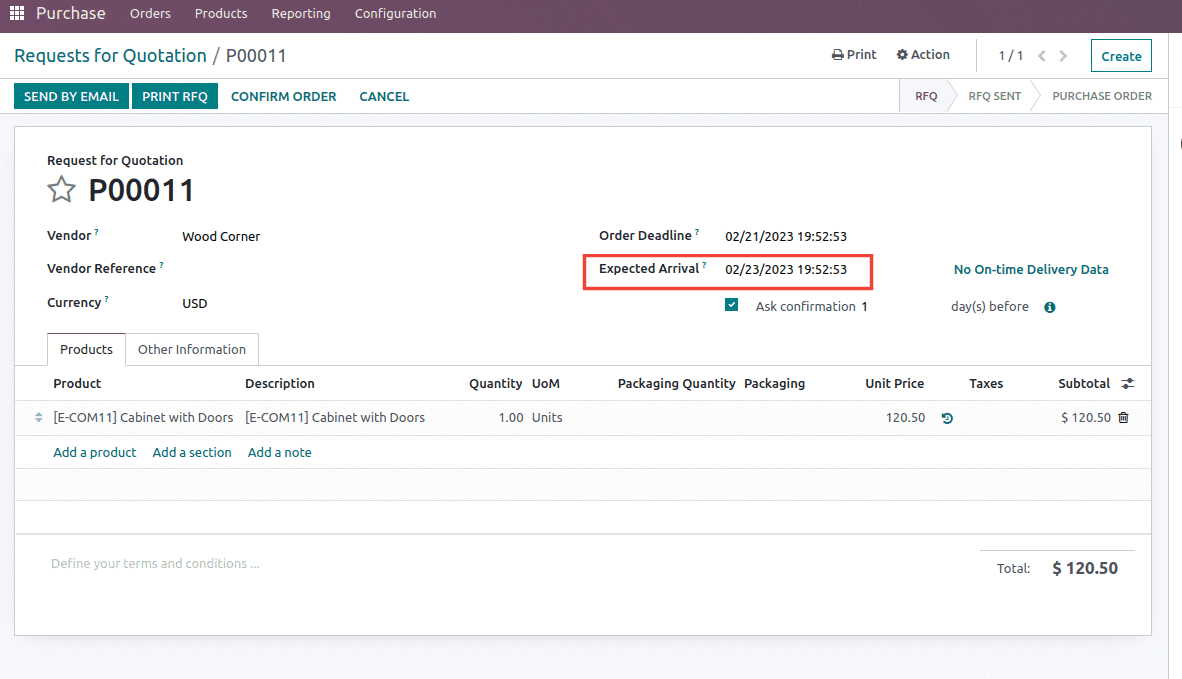

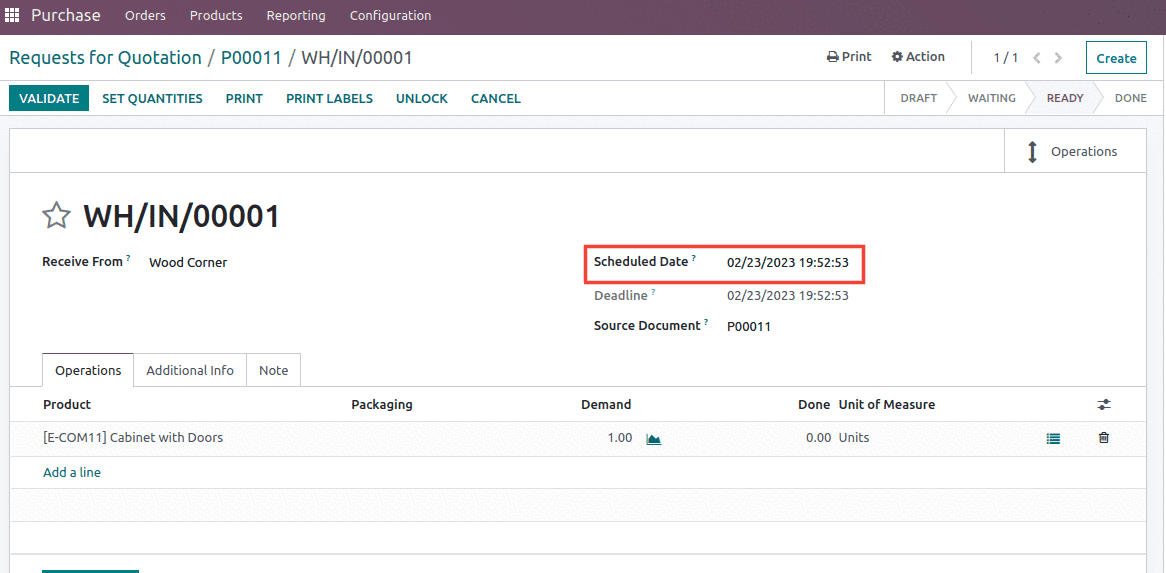

There is a field in the vendor pricelist page where you can enter the Delivery Lead Time. If specified, the order date of the purchase order plus the delivery lead time will now determine the delivery day for each order of that product. If you wish to take delivery speed into consideration when making orders, keep this information handy as different vendors may have varied lead periods.

As shown in the below image the vendor lead time is set as two days.

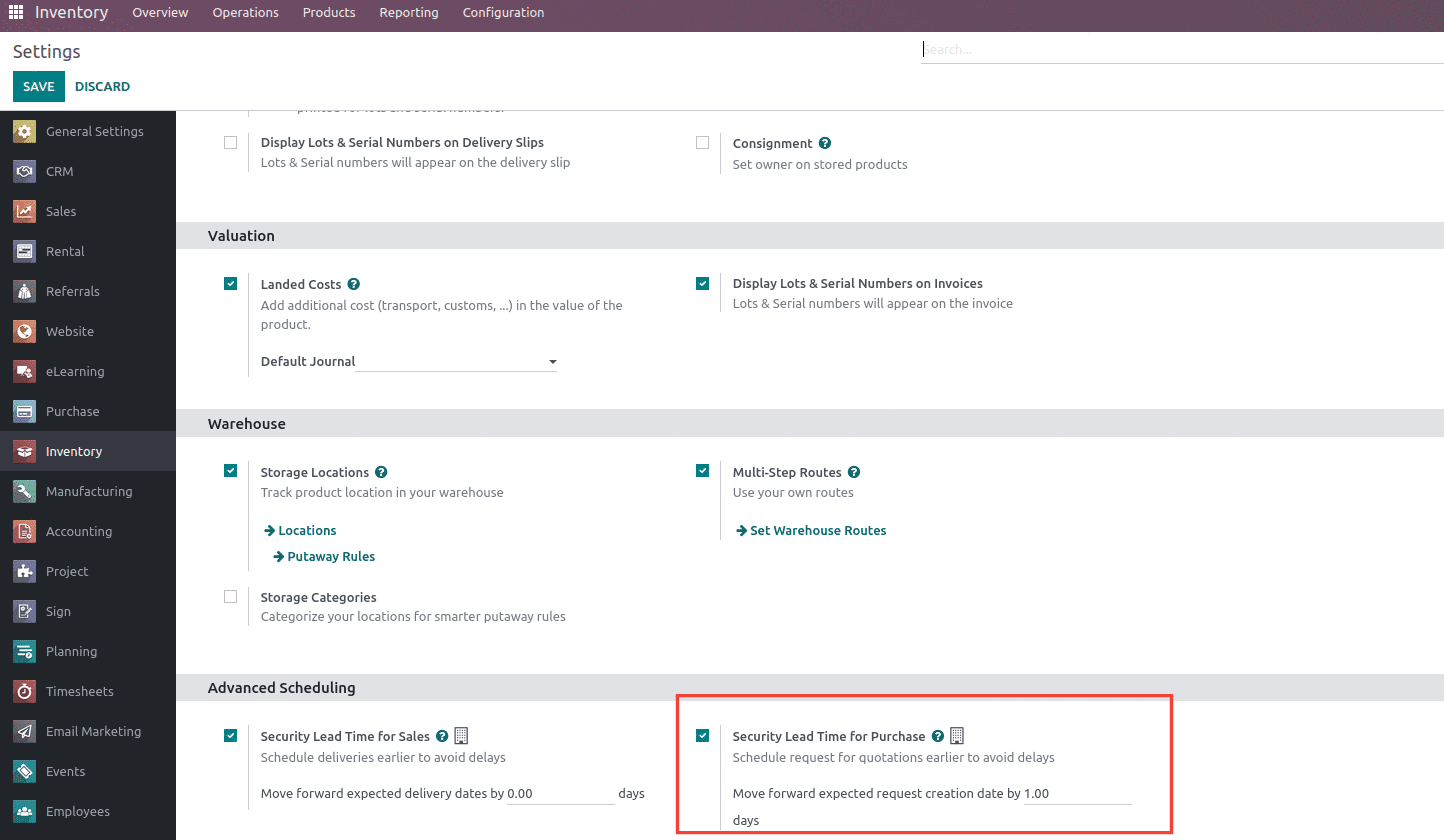

Security Lead Time for Purchase

The idea behind Security Lead Time for Purchasing is the same as that of Security Lead Time for Sales, with the exception that you are the customer, who monitors the padded time your supplier has to fulfill your item. By setting this date, you should be able to account for any vendor delays. Go to Inventory Configuration Settings and turn on Security Lead Time for Purchase to set it up.

Manufacturing Lead Time

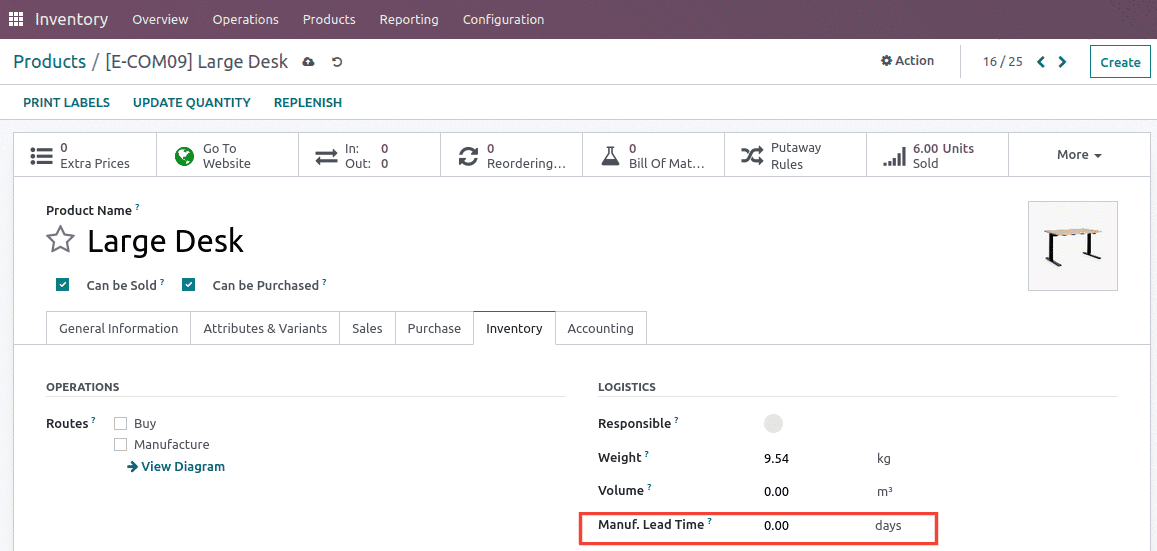

The time required to manufacture the goods is known as the manufacturing lead time. By selecting the Inventory tab of your product form and entering the number of days required for manufacture, you can set this parameter at the product level. In addition to helping you prioritize daily chores, this enables you to plan a start date for the order’s manufacturing.

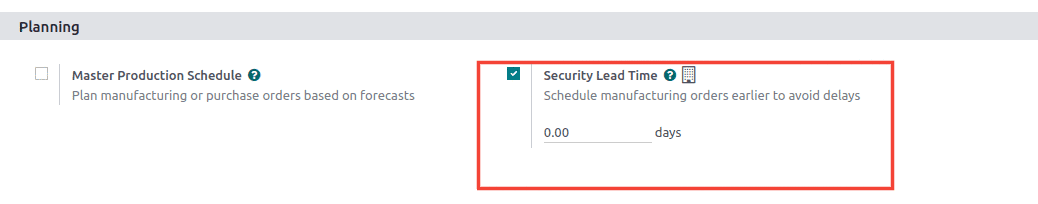

Security Lead Time for Manufacturing

Security lead time for manufacturing is an extra time to reduce the chance of a manufacturing delay. This is beneficial in circumstances of high order volume, as well as to account for maintenance or administrative delays.

It’s crucial for business that clients receive the best service available. It entails scheduling all actions, including manufacturing orders, deliveries, receptions, and so on. To do this, you must appropriately configure lead time and arrange scheduled dates. Lead time can be used to manage the operation in the easiest way in different business operations.

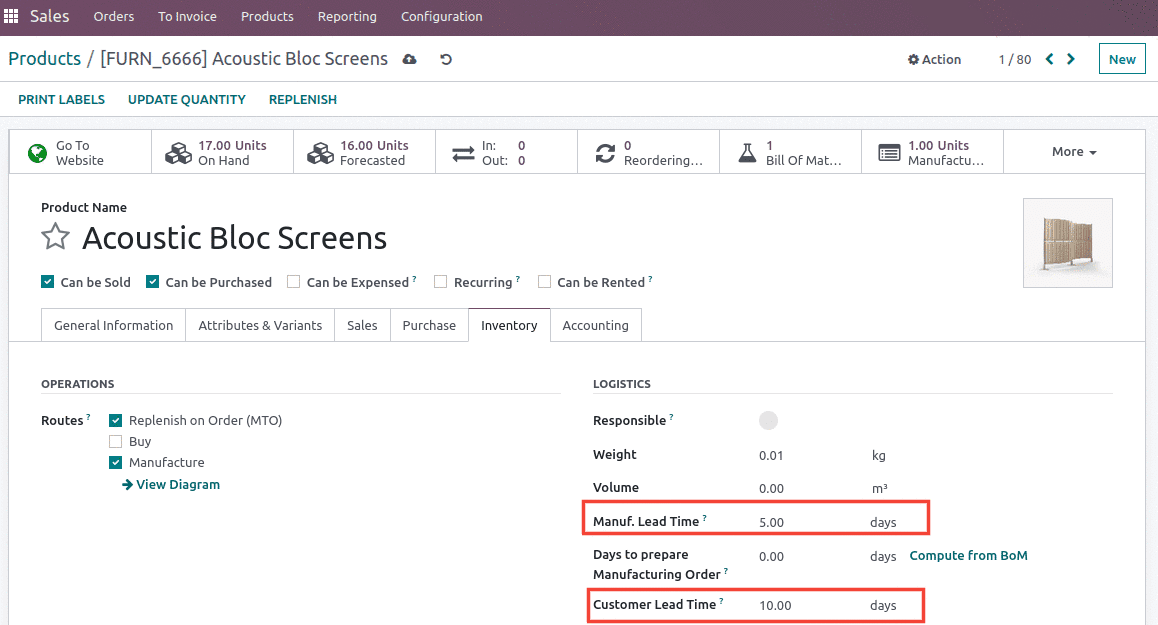

In general if we consider a case where the customers orders a product and if the product is out of stock and needs to be manufactured for which we need to purchase the components of the products from the vendor so this scenario can be effectively managed and delivered to the customers on time with the help of lead time, Now lets see it with an example where the customers orders a product which is unavailable and needed to be manufactured so lets create a Sale Order for a customer before that to deliver the product on time to the customer let’s set the Customer lead time and along with that if the product is not available and need to be manufactured and in order to avoid the delay from vendors in receiving the product and to manufacture lets assign vendor lead time to the components of the product and manufacturing lead time to the product as shown below.

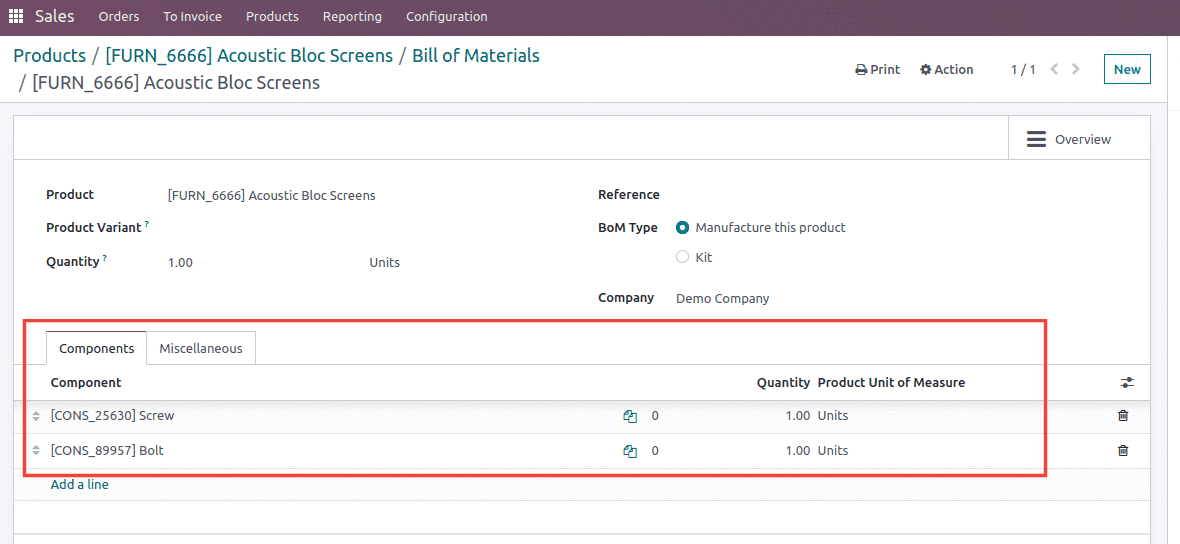

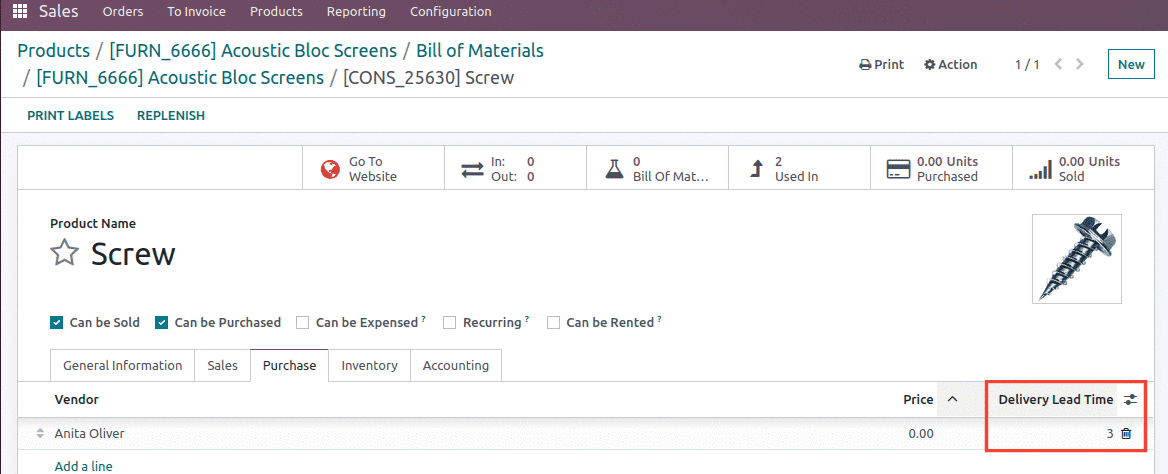

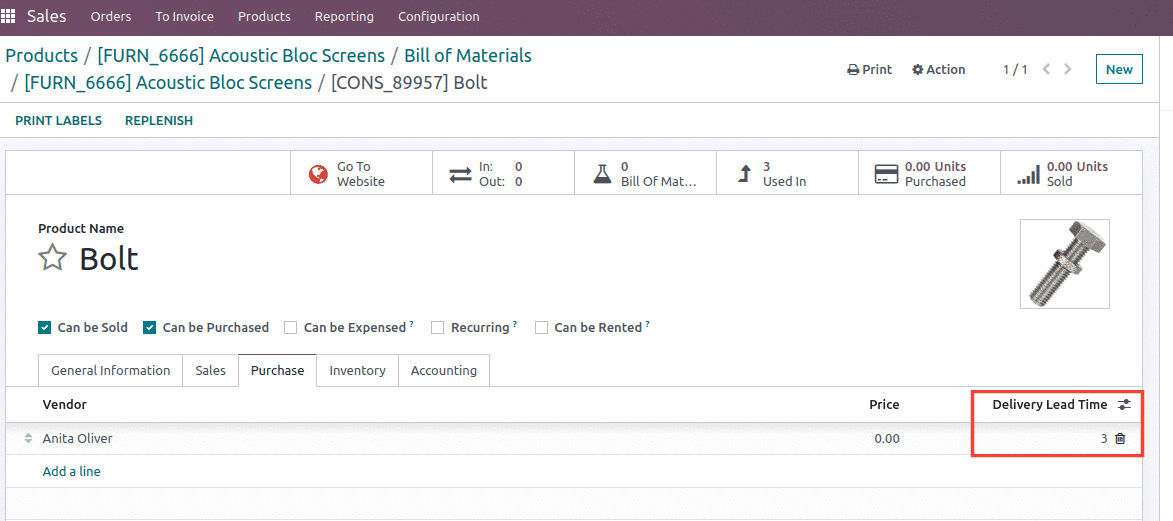

Since there is the need to manufacture the main product and there is no sufficient inventory of the components of the main product and that need to be purchased from the vendor, so for those components also we can set the lead time.

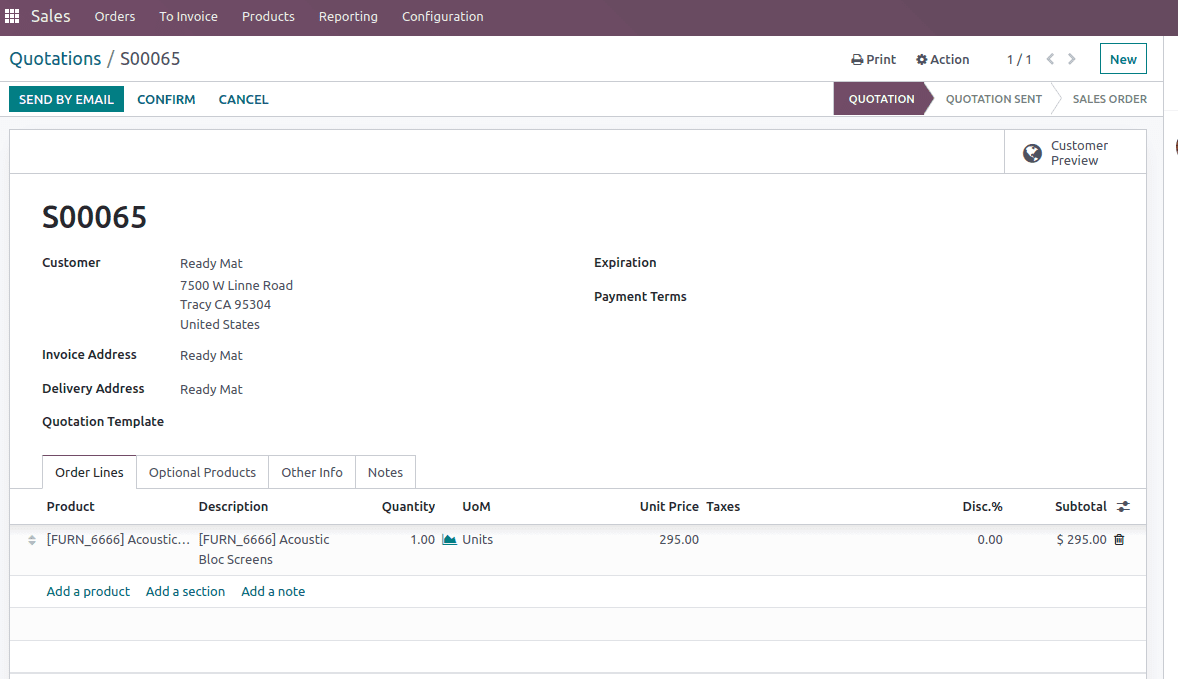

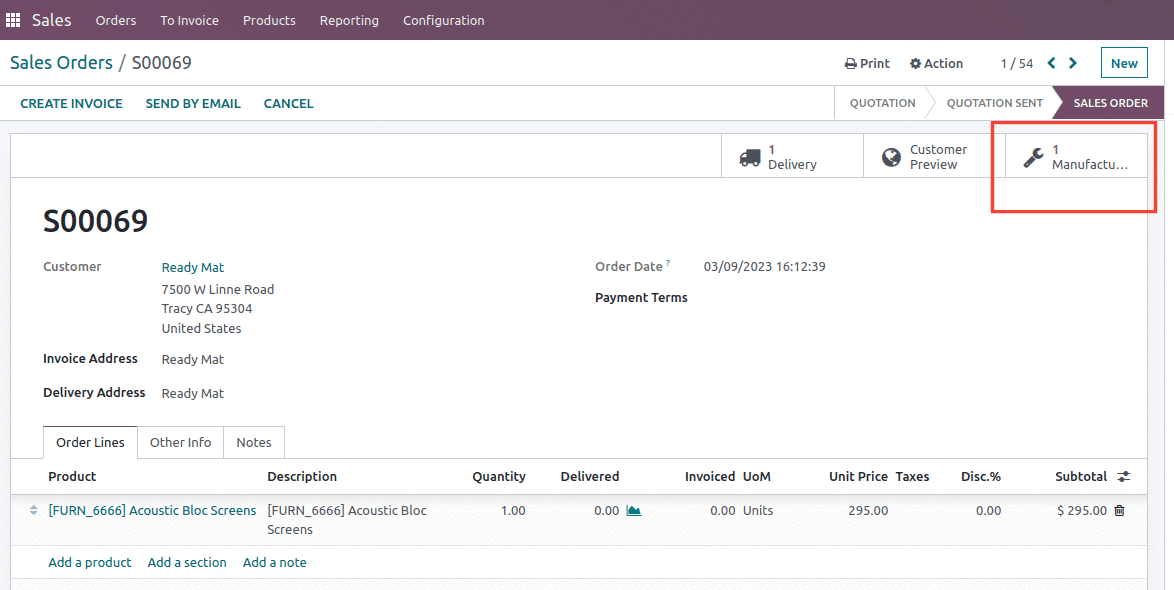

Now lets create a sale order with order date 09/03/2023 to the above products in the order line as shown below;

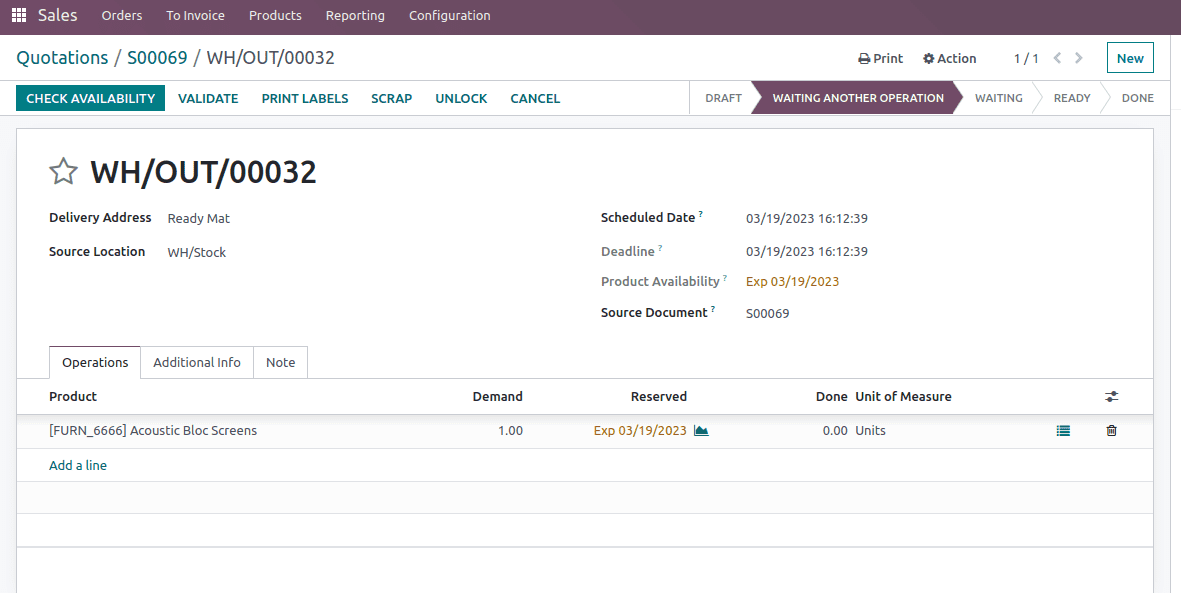

Once the sale order is confirmed we can see that the scheduled date is updated to 19/03/2023, because the Customer lead time was set as 10 days as shown below in the screenshot.

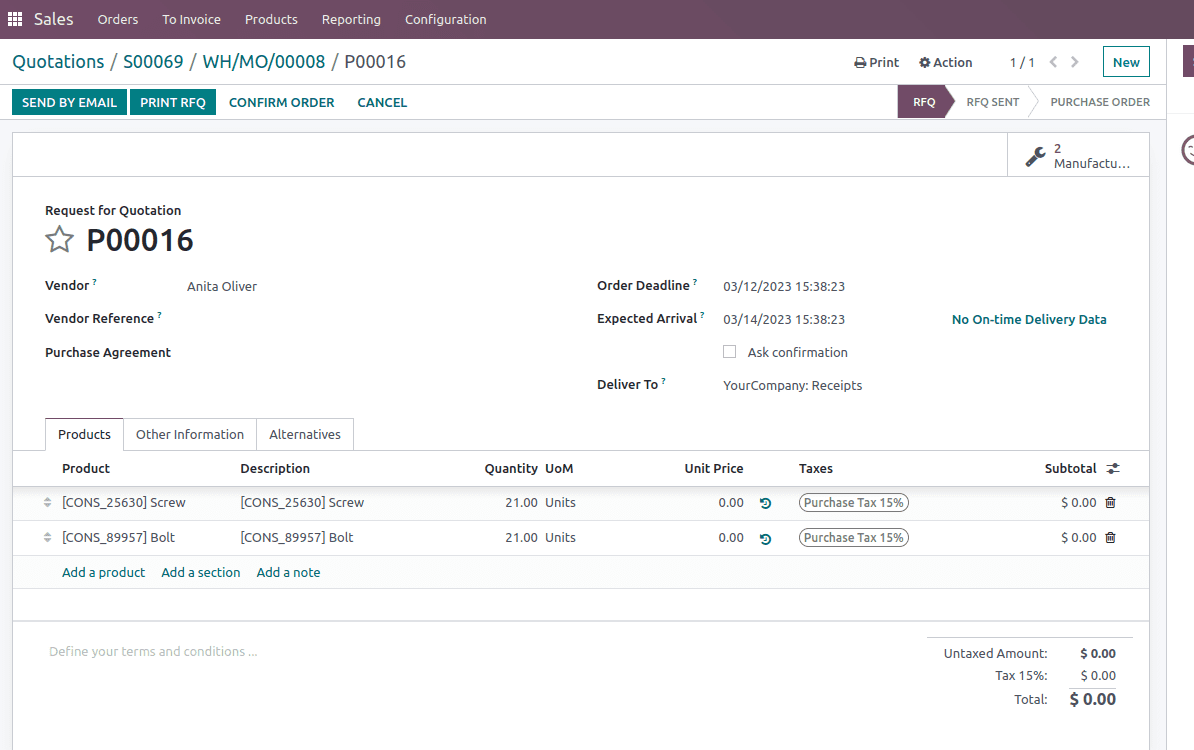

Now when the sale order is confirmed we can also see that along with the confirmation of sale order additional smart button of Manufacture is added on because for the product, we have set the route as Manufacture and Replenish on Order (MTO) and inside the manufacturer smart button the purchase order smart button is created which contain the components to manufacture the product as despite in below screenshot.

Here in the above screenshot it shows that the manufacturing order WH/MO/00008 is scheduled for 14/03/2023 this is because for this product we have added the manufacturing lead time as 5 days.

Similarly inside the Purchase tab one can see that the Order deadline for the purchase order is set as 12/30/2023 this is because for the components Screw and Bolt the vendor lead time is set as 3 days.

So here one can see how the operations are managed very effectively with the lead time option which helps to make the business operation flow easy without any conflicts.