Lots are a collection of identical products in a single pack or batch. This entire batch is identified and tracked by this Lot number. Managing and delivering a batch of a product under a single identity is much easier than managing by single products.

Odoo provides the concept of ‘Lots’, by which a group of products can be identified using Lot number. Lot numbers and serial numbers are used for the same purpose, ie identification of products. But a lot stands for a batch of similar products, while serial number stands for an individual product.

Lots are mainly used when you receive a bulk amount of product and this will also help in reporting, quality control, etc. But for some consumable products like kitchen rolls, toilet papers, pens, etc have a fewer chances to return if any production fault is identified. So this kind of product store with lots makes no sense.

[wpcc-iframe loading=”lazy” width=”100%” height=”315″ src=”https://www.youtube.com/embed/nxbThA0YmjY” frameborder=”0″ allow=”accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture” allowfullscreen=””]

Configuration

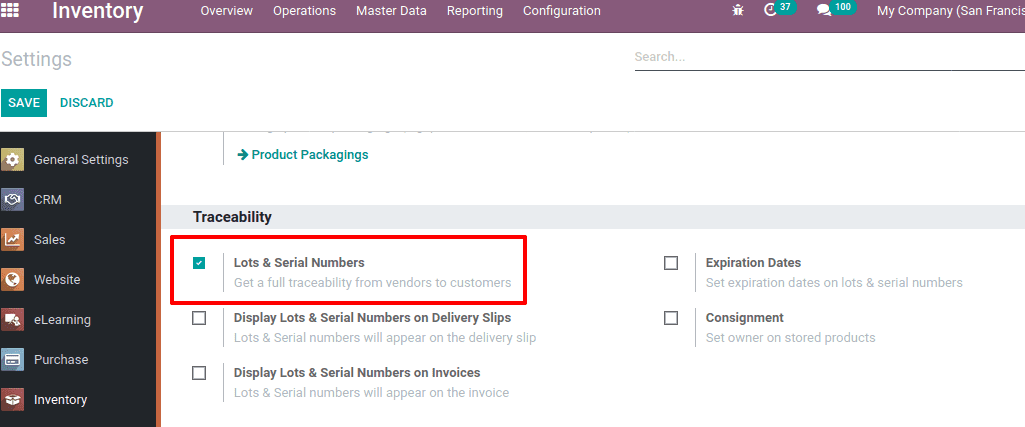

To manage and trace the product by Lot number, firstly enable ‘Lots & serial number’ under configuration settings of inventory.

Inventory > Configuration > Settings > Traceability > enable Lots & Serial Numbers and Save

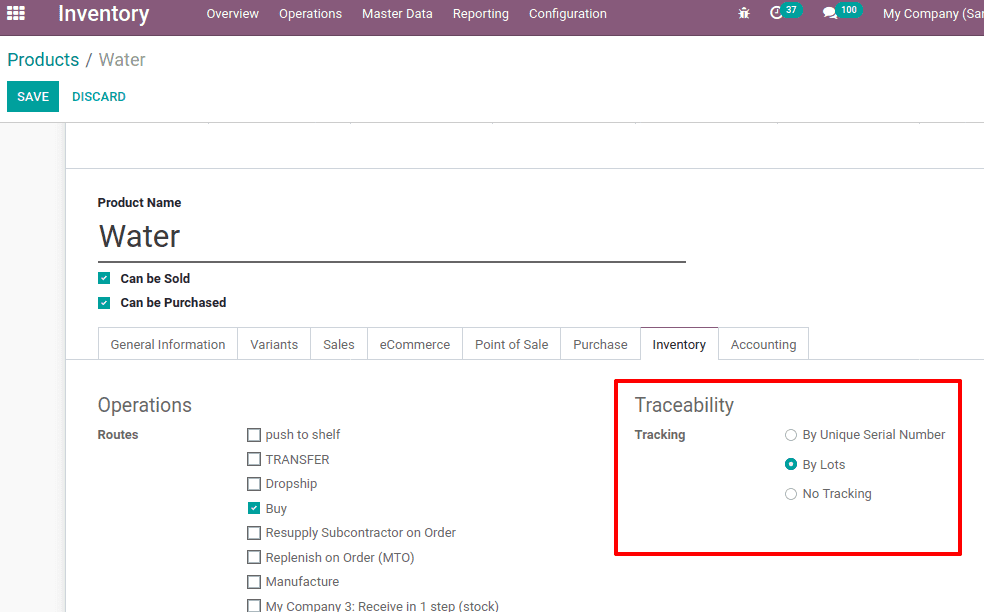

Product configuration

Once the traceability is enabled, one can find the traceability feature inside the product form. Configure any product with traceability lots.

Go to Inventory > Master data > Products, choose any of the products upon your requirement.

The tracking method is set as ‘By Lots’ for the product Water. So they can sell as a batch like bottles of 50 units under a single lot number.

Now let’s look at how Lots can be managed.

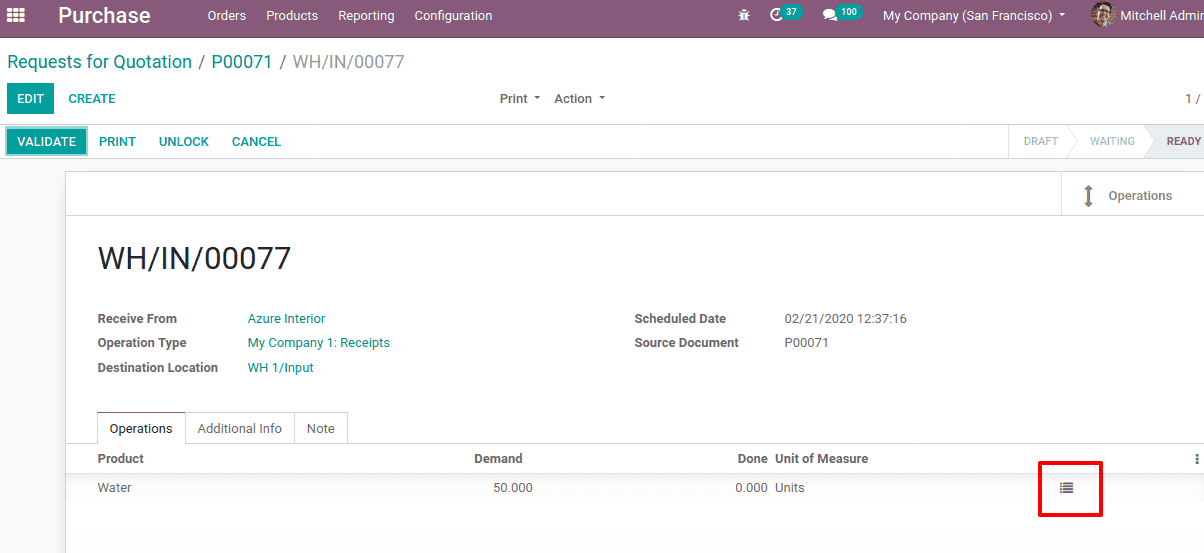

Now create a purchase order for the configured product, so that you will get an option to enter the Lot number for the product while receiving it.

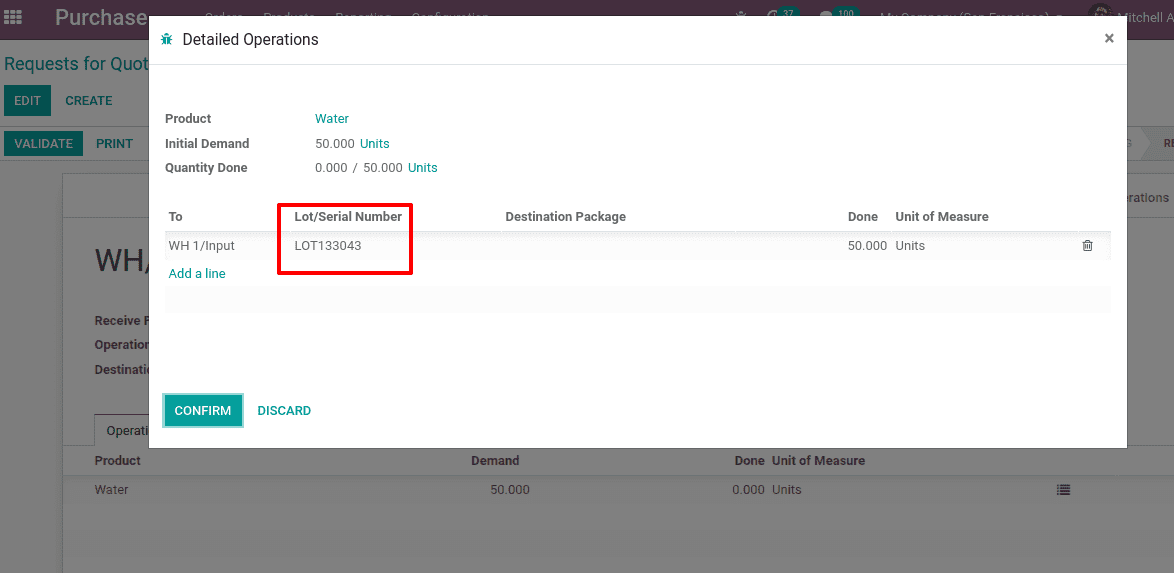

Click on the Lot split button shown in the above image, it will redirect to another window to enter the Lot number.

One can assign a Lot number and Done Quantity and click on CONFIRM. Now validate and receive the product.

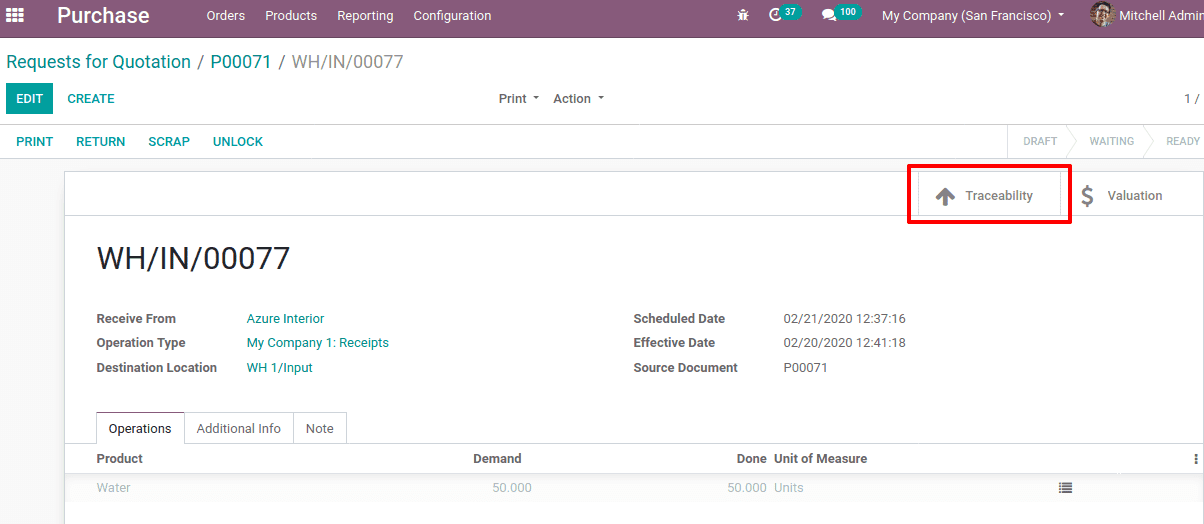

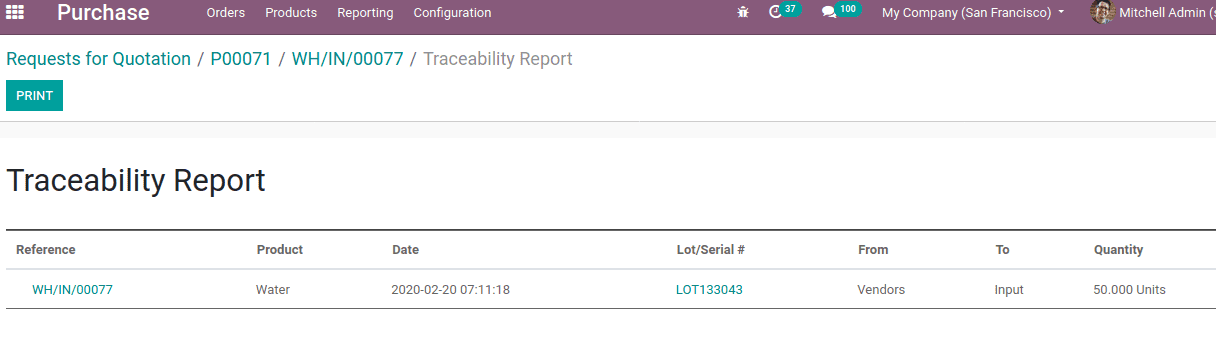

Now you can find a smart tab ‘Traceability’. The traceability report of the product with Lot is shown below.

The lot number given for the product will allow you to track the product in the inventory. Hence the purchased product is entered into the inventory along with a Lot number.

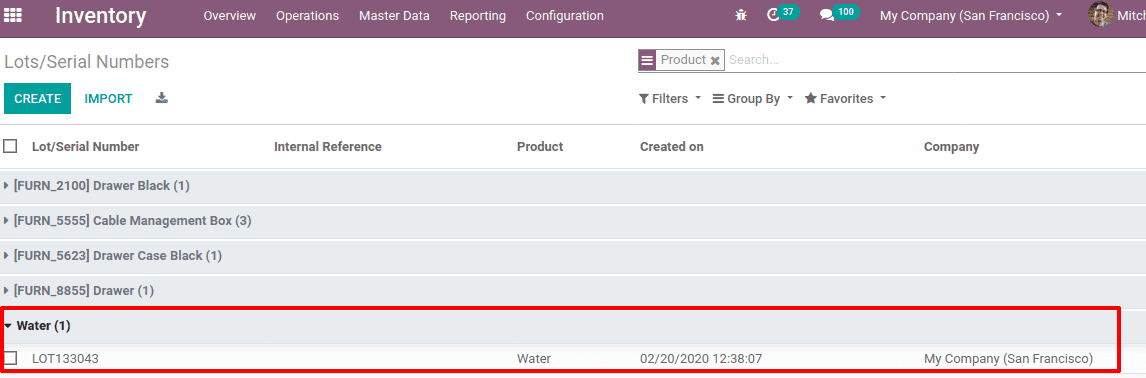

Move to the Inventory module, all products with Lots are available under:

Inventory – >Master Data -> Lots/Serial Numbers.

The inventory of the product tracked by the product name is shown below.

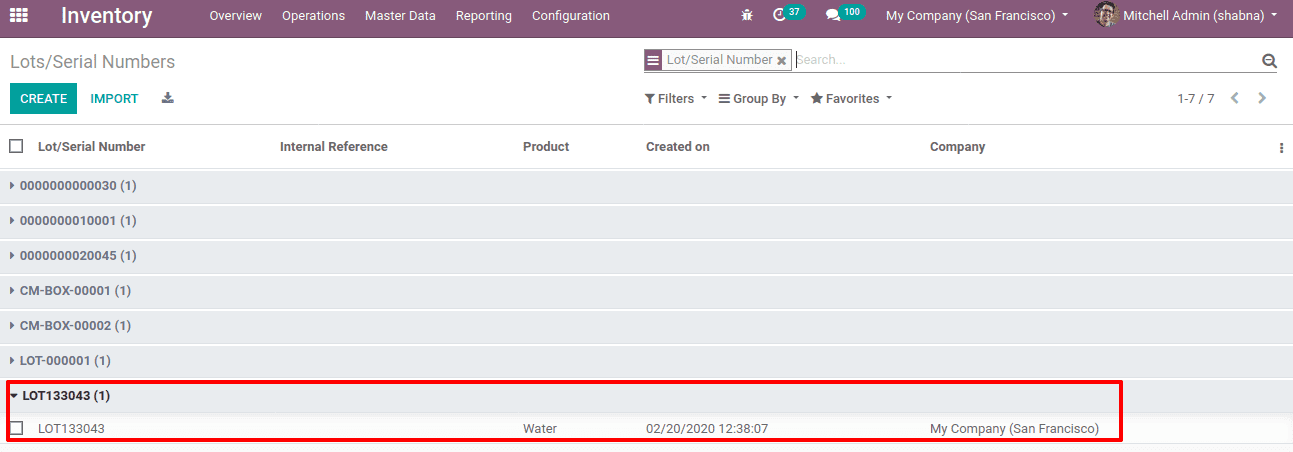

One can track the inventory of a product by Lots as well. Using the group by’ option, add a custom group Lot Number, so you can track the inventory of the product using Lot as below.

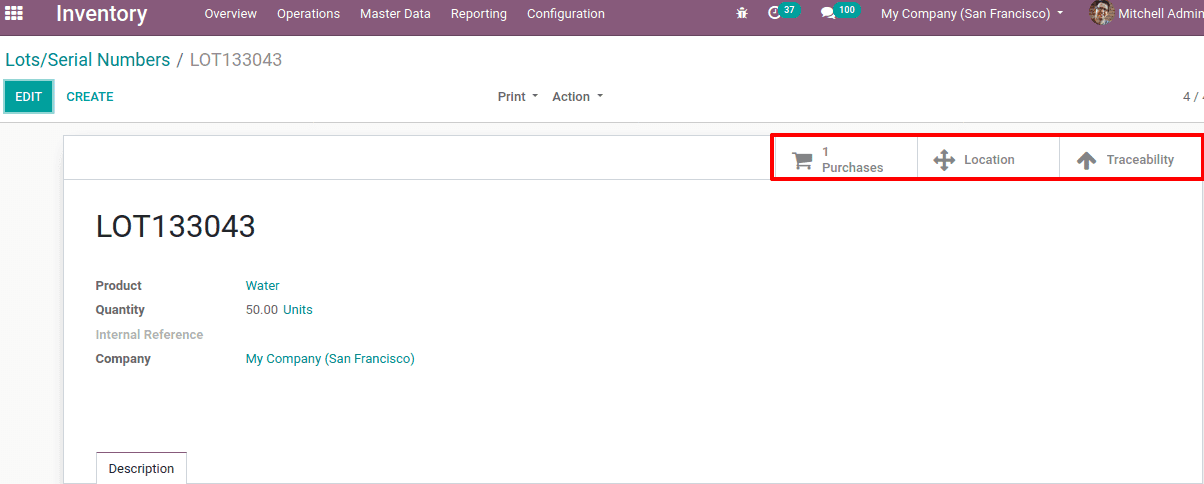

When you click on the lot number it redirects you to another window, where you can find the details of the lot.

Three smart buttons regarding this lot can be seen there. User location, Product locations can be tracked.

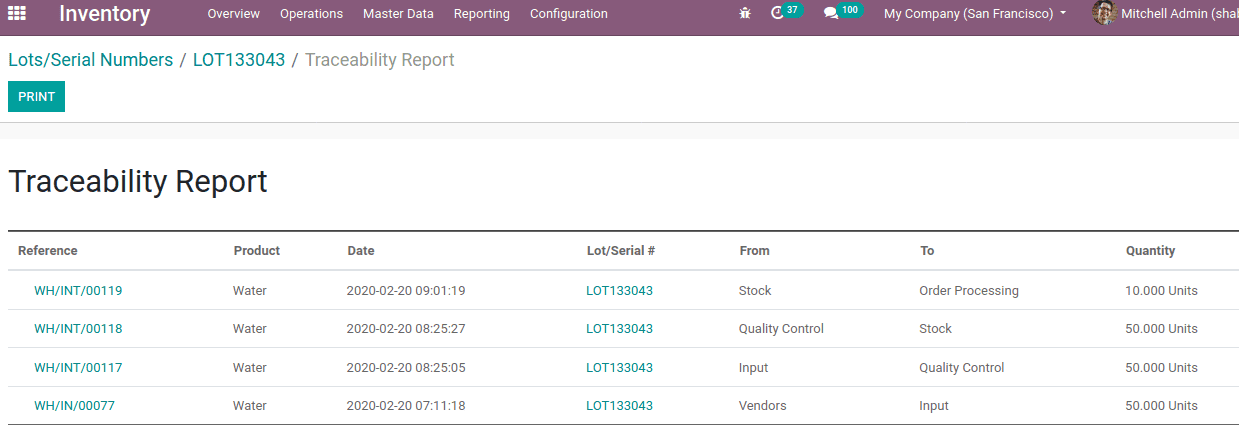

The traceability will record the product moves from the purchaser to the inventory location.

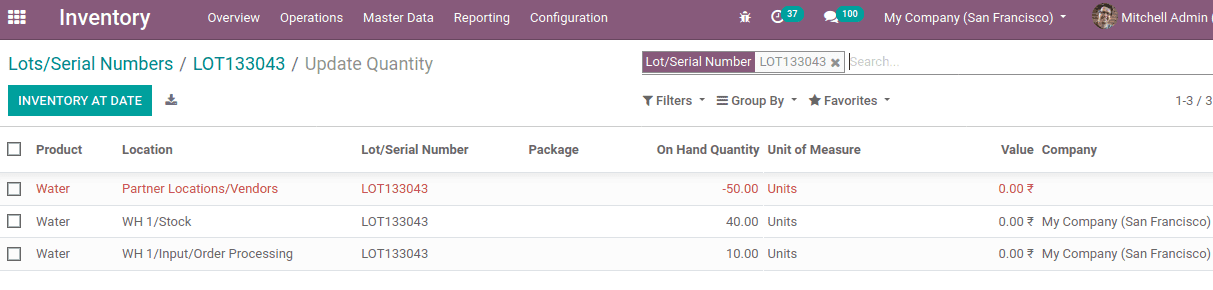

Here you can find the movement of the product from the vendor to stock and stock to order processing. Upon receiving a product of 50 quantities under a batch, it is moved from the vendor to the stock. Then 10 quantities of product with the same lot is transferred to order processing from the stock.

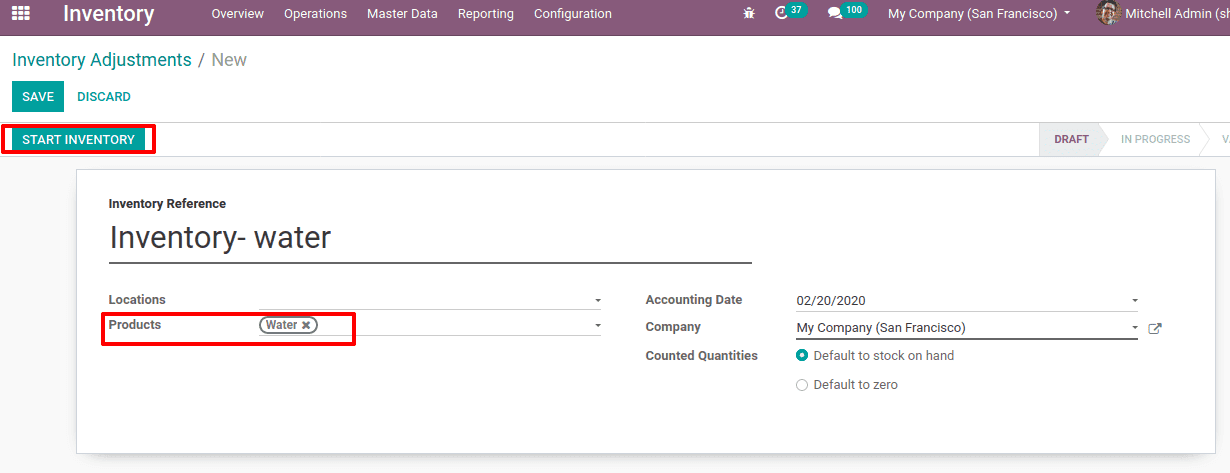

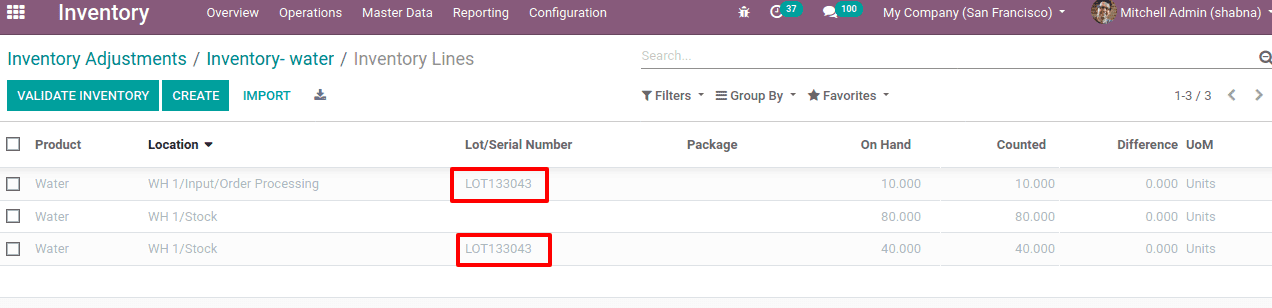

Now go inventory adjustments for this product, Inventory > Operation > Inventory adjustments.

Add product at the product field and click on START INVENTORY.

Now the inventory lines show the current locations of the product. We can identify it with the help of a lot.

In the above case, 50 quantities of products are totally purchased with lot number LOT133043. Then, 10 products from 50 units are transferred to order processing. Now, these products under the same lot can be traced as 40 units are in the stock itself and the remaining 10 units in order processing.