To optimize operations and boost productivity, businesses require production management software. Effective resource management is important for firms in today’s cutthroat economy. Software designed for manufacturing operations is frequently used to control revenue growth and profitability. ERP (enterprise resource planning) systems, which offer thorough control over all business activities, are created specifically for manufacturing. As a result of these systems, output and customer service are eventually increased along with company development, revenue growth, and quality improvement.

Reduced redundancy, automated procedures, better supply chain, warehouse, transportation, inventory management, risk reduction, enhanced customer service, departmental integration, real-time reporting, centralization of operational and financial data, and adaptability to business changes are just a few advantages that manufacturing management systems provide. An effective tool for handling manufacturing orders, bills of materials, and work centers is the Odoo 16 Manufacturing Module, an ERP system that simplifies scheduling and planning at every level. To provide effective monitoring of requests, quality alerts, and component approval procedures, it incorporates Maintenance, Product Lifecycle Management (PLM), and Quality modules. For industrial businesses, this connection guarantees ongoing communication and network development.

Master Production Scheduler In Odoo Manufacturing

In the Manufacturing module of Odoo 16’s enterprise edition, there is a production forecasting mechanism called Master Production Planning. It calculates product demand based on forecasts and allows users to adjust values if necessary. This feature is beneficial for manufacturers planning production in line with market demand, helping them estimate required product quantities to meet demand. It is essential for meeting market demands and ensuring efficient production.

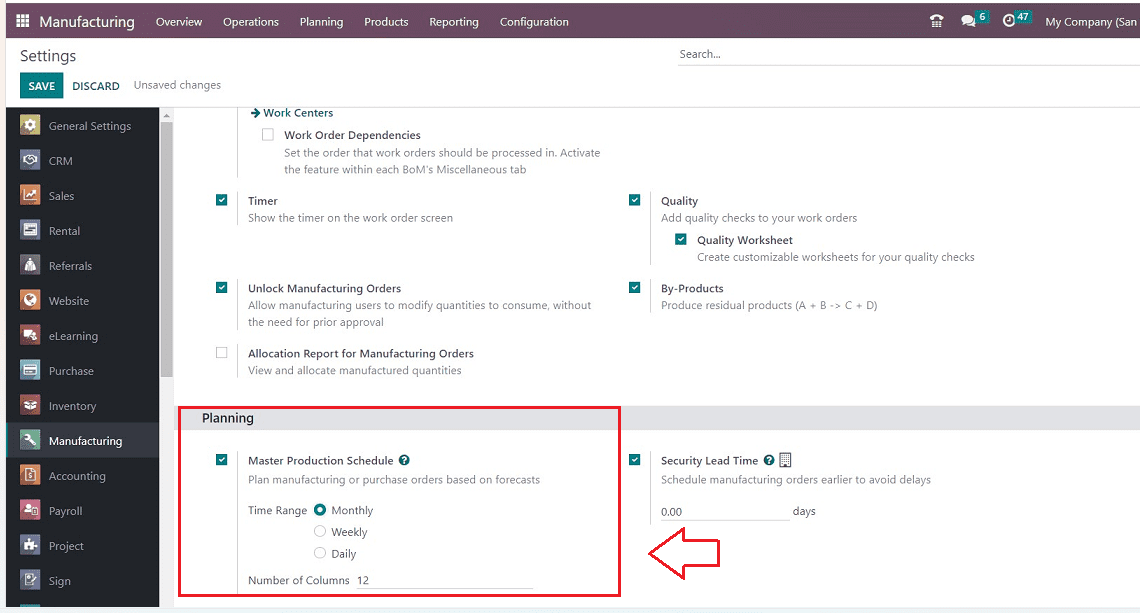

To configure the Master Production Scheduler functionality, you can activate the “Master Production Schedule” option from the “Settings” tab of the Odoo 16 Manufacturing Module.

The time range of your Master Production Scheduler (Month, Week, or Day) and the number of periods you wish to display constantly may both be specified in the Master Production Scheduler (MPS) options.

Planning a new Master Production Schedule

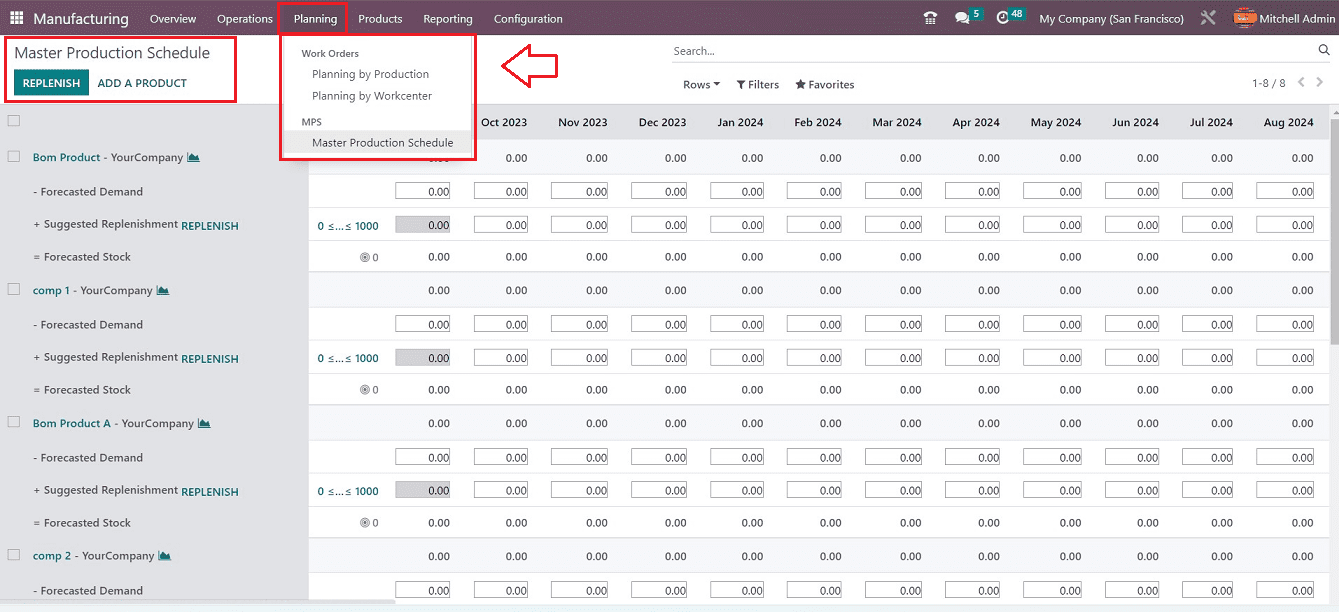

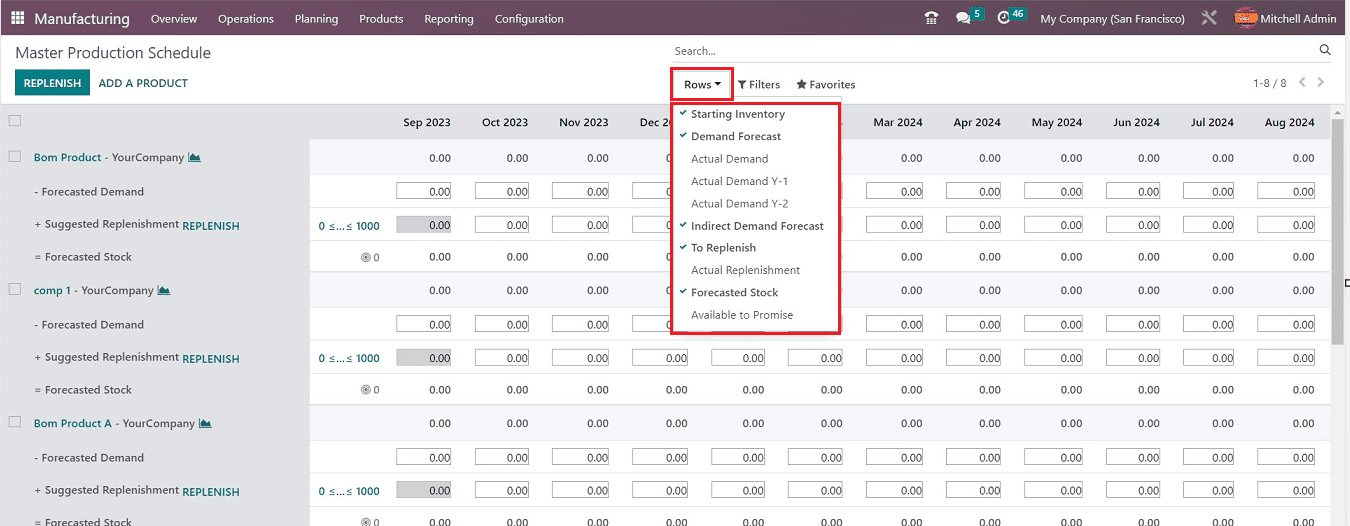

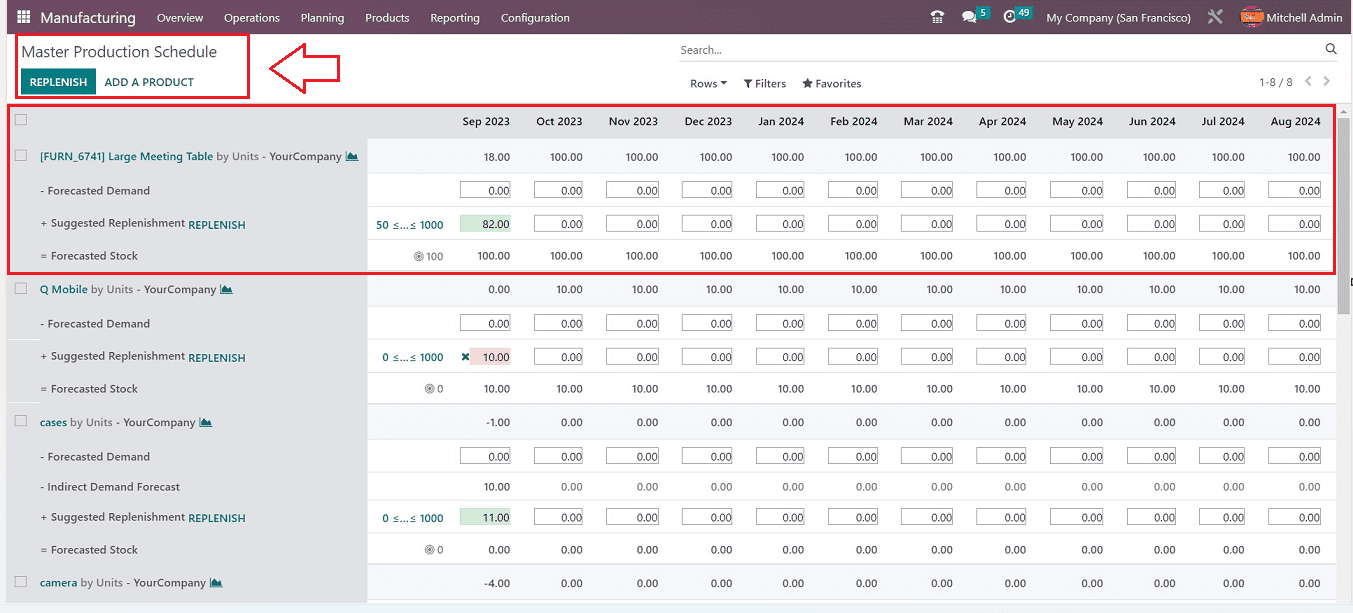

To plan a new MPS for your Manufacturing Unit, go to the “Master Production Schedule” option available in the “Planning” menu, as illustrated in the screenshot below.

By clicking on the “Rows” option available in the MPS view, you can choose which information is displayed. This includes the following variables: Starting Inventory, Actual Demand, Indirect Demand Forecast, To Replenish, Actual Replenishment, Forecasted Stock, and Available to Promise.

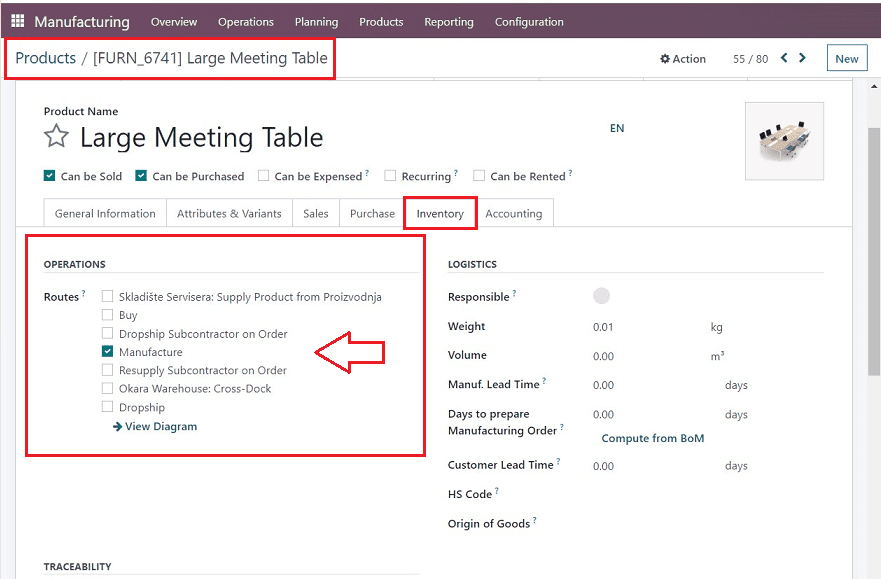

Odoo can only produce a manufacturing order upon replenishment if the route of operation of the relevant product is set to “Manufacturing” when it is added to the MPS. You can change the product route by opening the particular form view from the “Products” menu, as depicted in the screenshot below.

Adding a New Product

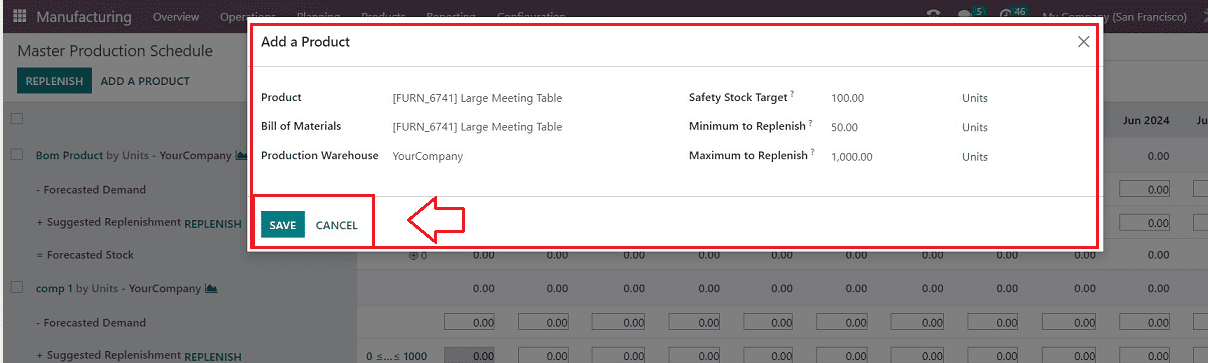

You can add a new product to the Master Product Schedule using the “ADD A PRODUCT” button. This button will trigger a Pop-up form window, as displayed below.

The product details can be provided inside the form view, including the Name of the “Product,” “Bill of Materials,” and “Production Warehouse.”

Mention the minimal free stock you wish to keep on hand at all times for the product listed in the “Safety Stock Target” field. If you provide the “Minimum to Replenish,” Odoo will always replenish at least that amount until the demand is zero. The amount shown in the “Maximum to Replenish” denotes the most amount of replenishment you wish to deploy for each MPS product. The remainder will automatically be carried over to the following period if the demand exceeds this amount. After completion, press the “SAVE” button.

There are currently 18 units of the product in stock. It is possible to obtain information on the stock for the upcoming year, and it will be published on a monthly basis. The projected demand can be manually entered in the “Forecasted Demand” column. The “Suggested Replenishment” section shows the recommended refill quantity. The quantity of stock available at the end of the period will be indicated within the “Forecasted Stock” field.

Odoo will create a manufacture or purchase order depending on the product’s operating path when the “REPLENISH” button is selected. The orders created with MPS as the source will be shown inside the Manufacturing Orders portal.

To read more about overview of workcenters & operations in Odoo 16 manufacturing, refer to our blog An Overview of Workcenters & Operations in Odoo 16 Manufacturing