In manufacturing, the Maintenance program plays an essential role in managing efficiency. It can definitely be considered as health care for manufacturing machines. Health care that reduces waste and runs appropriate continues manufacturing operations. As you know in such a busy economic schedule we don’t really want to waste money dealing with insignificant breakdowns acquiring a loss of revenue. Odoo v13 Maintenance Module provides great Calender and Kanban views you can easily track or organize the progress of the maintenance request and for planning and organizing activities. You can also use the maintenance calendar. It has a very effortless and spontaneous interface of easy drag and drops to assemble the maintenance request. With the effective Maintenance, it helps to boost the overall equipment efficiency. Through directly from the work center control panel the manufacturing department can enhance the maintenance requests.

[wpcc-iframe loading=”lazy” width=”100%” height=”409″ src=”https://www.youtube.com/embed/sl3AyKJ9a8o” frameborder=”0″ allow=”accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture” allowfullscreen=””]

The Blog discusses more on Odoo v13 Maintenance Management:

Product Maintenance in Odoo can be be done in two ways;

1. Preventive

2. Corrective

Preventive maintenance is a process mainly aimed to achieve the goal of expanding the lifetime of an asset by controlling or preventing excess devaluation or an unexpected breakdown. Basically preventive maintenance can be of two types, one is calendar-based maintenance and other is usage-based maintenance. Thus Preventive maintenance can be also said as equipment servicing done at regular intervals. So if you are thinking about how preventive maintenance helps you, here is the answer for you. It enhances the safety of equipment and helps in reducing the risk of injury, in the extension of asset lifetime optimizing the maintenance planning and resource allocation.

Corrective Maintenance, on the other hand, can be said as a supportive task carried out to differentiate, segregate and rectify an issue so that the malfunctioning equipment can be reconstituted to an operational stage.corrective maintenance is a simpler process and it is very easy to understand since one can only used to do is take spontaneous action when there comes any kind of problem for your equipment. And corrective maintenance needed very minimal complex planning.

So irrespective of what industry you are working in, whether your business is small scale or large scale, conducting or managing proper and effective maintenance of equipment is an inevitable factor for enhancing your business efficiency.

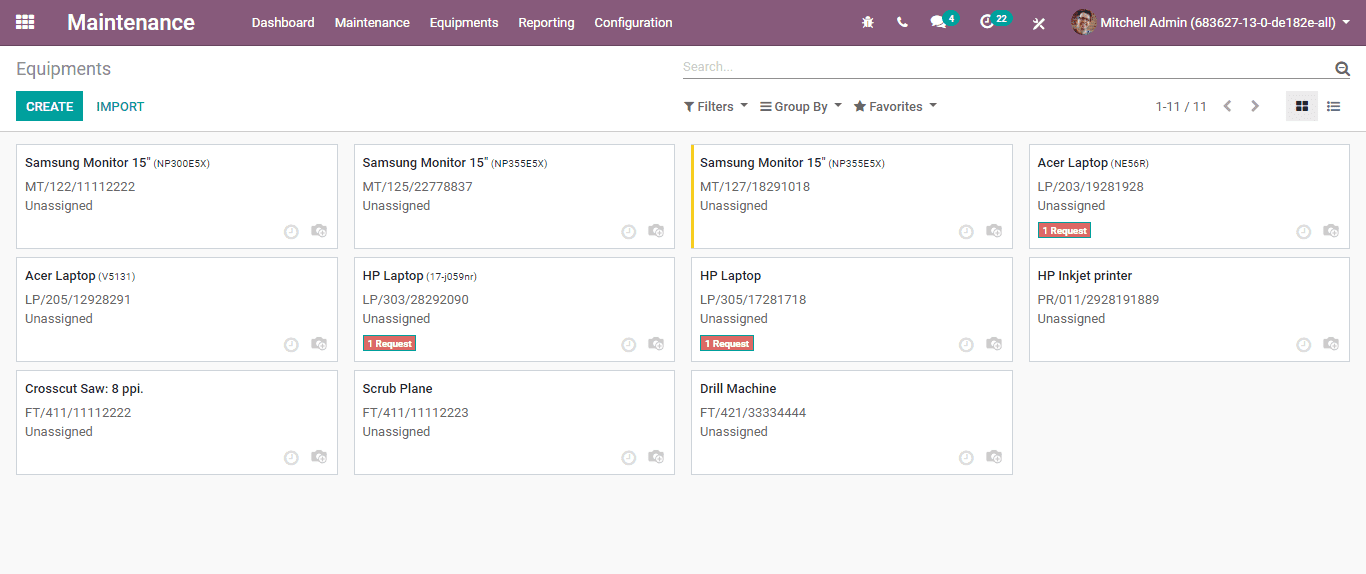

For maintenance management initially, you have to install the Maintenance module.

You can easily create equipment under this.

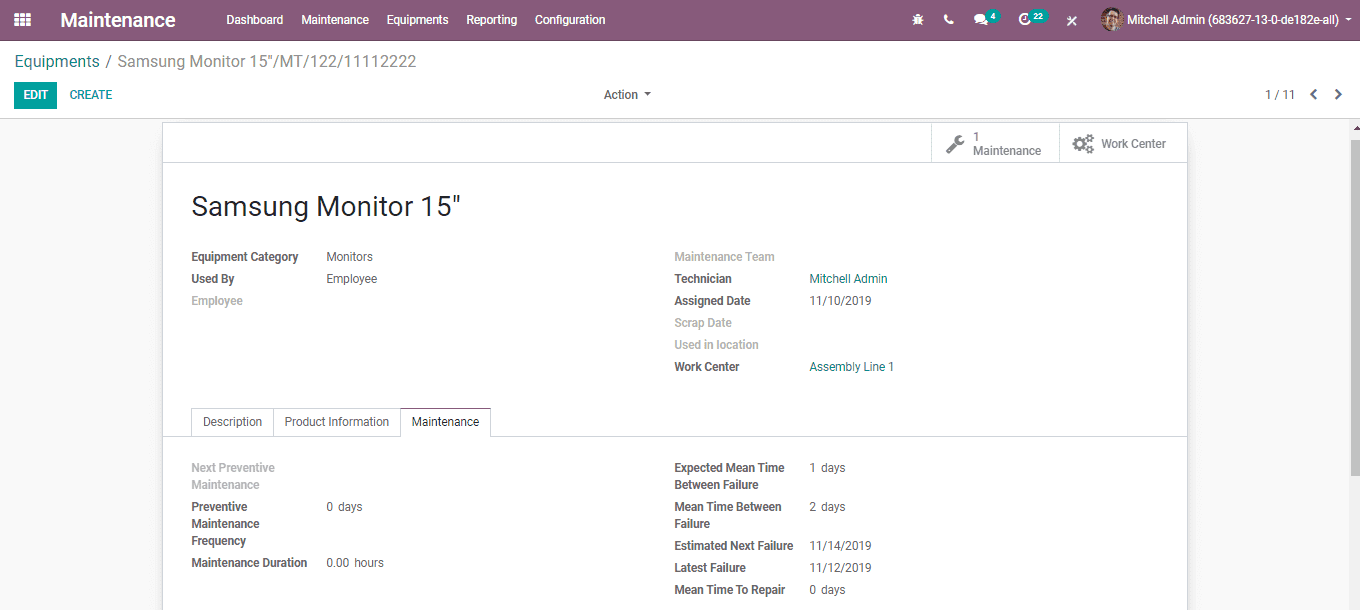

Creating the Equipment

For creating equipment, Select Equipment -> Machines and Tools -> Create.

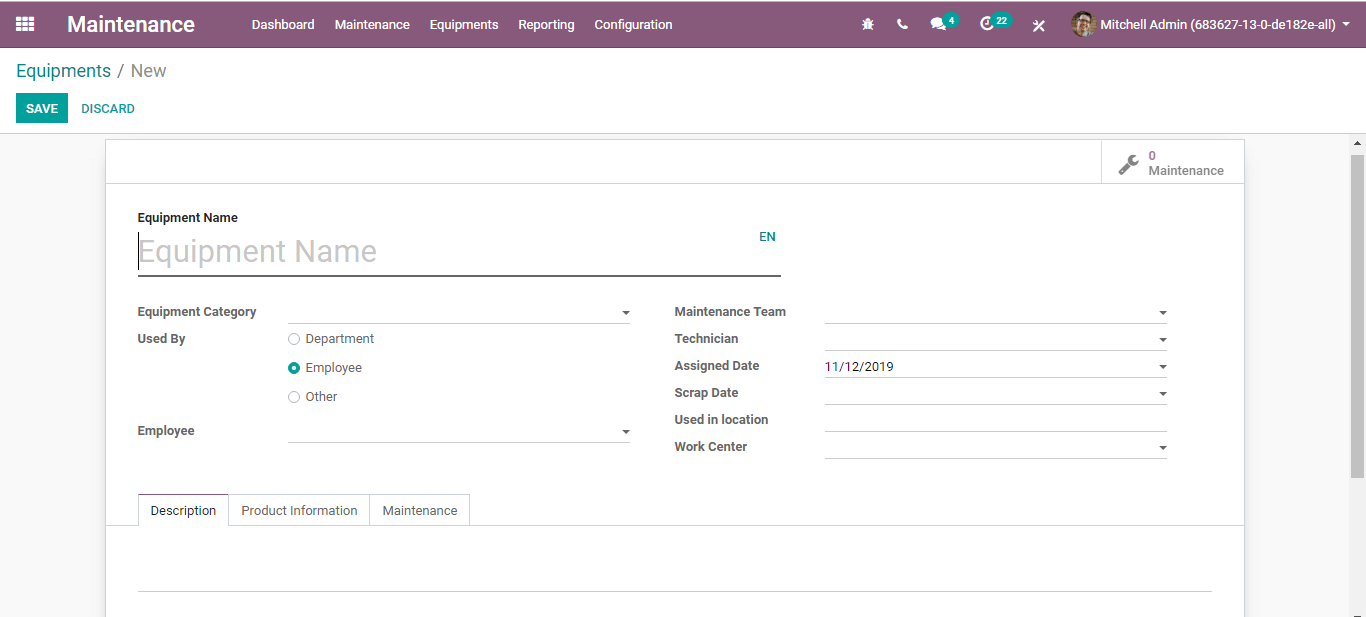

Click Create button so that you will get into a new window as shown below

Here is the time to complete the fields in the new window for form creation.

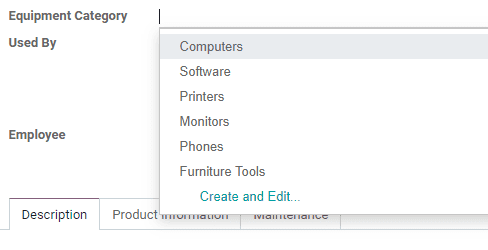

Equipment Category

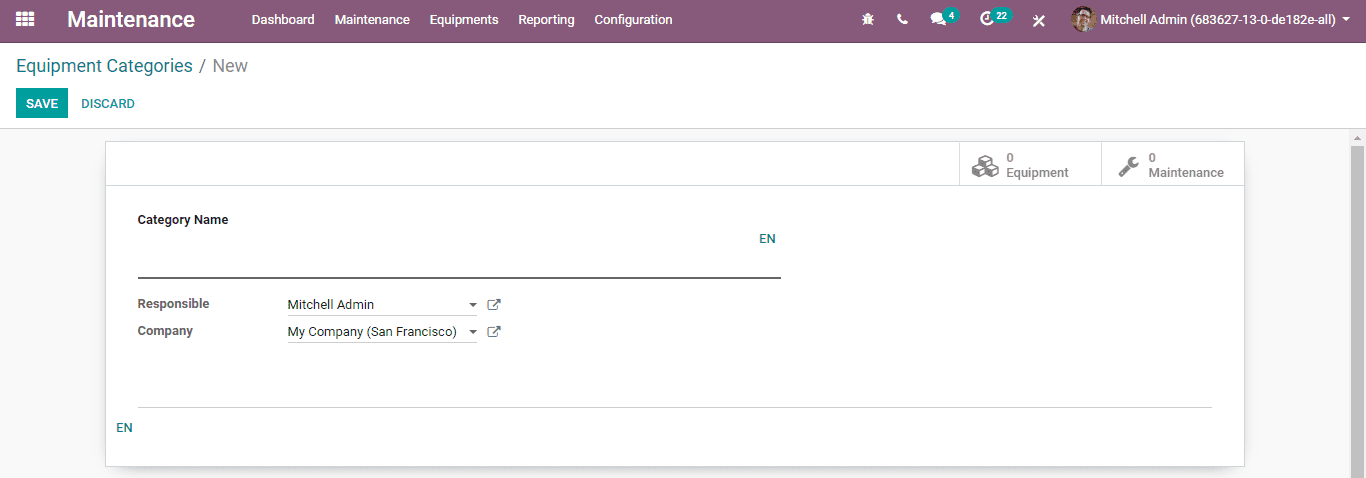

For choosing equipment category go to, Maintenance -> Configuration -> Equipment Category

So one can create a new Equipment category by clicking the Create Button.

You are allowed to define the Category name, responsible company/person and equipment category under this creation form.

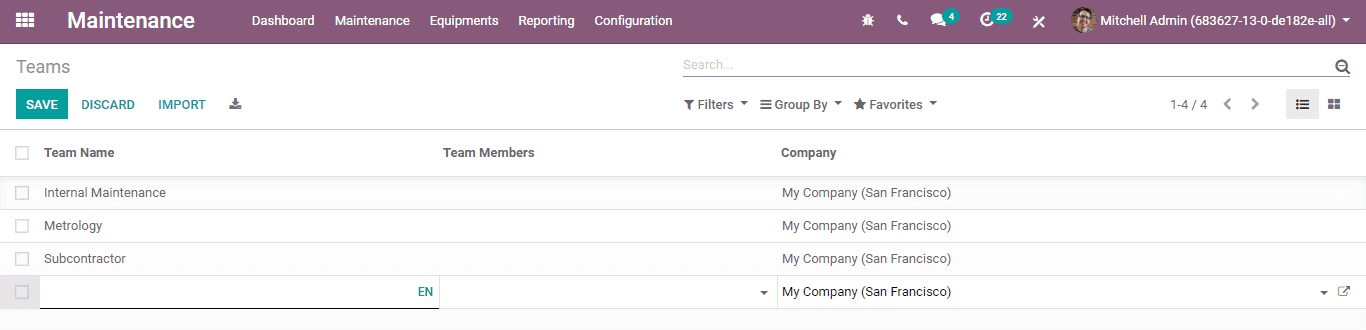

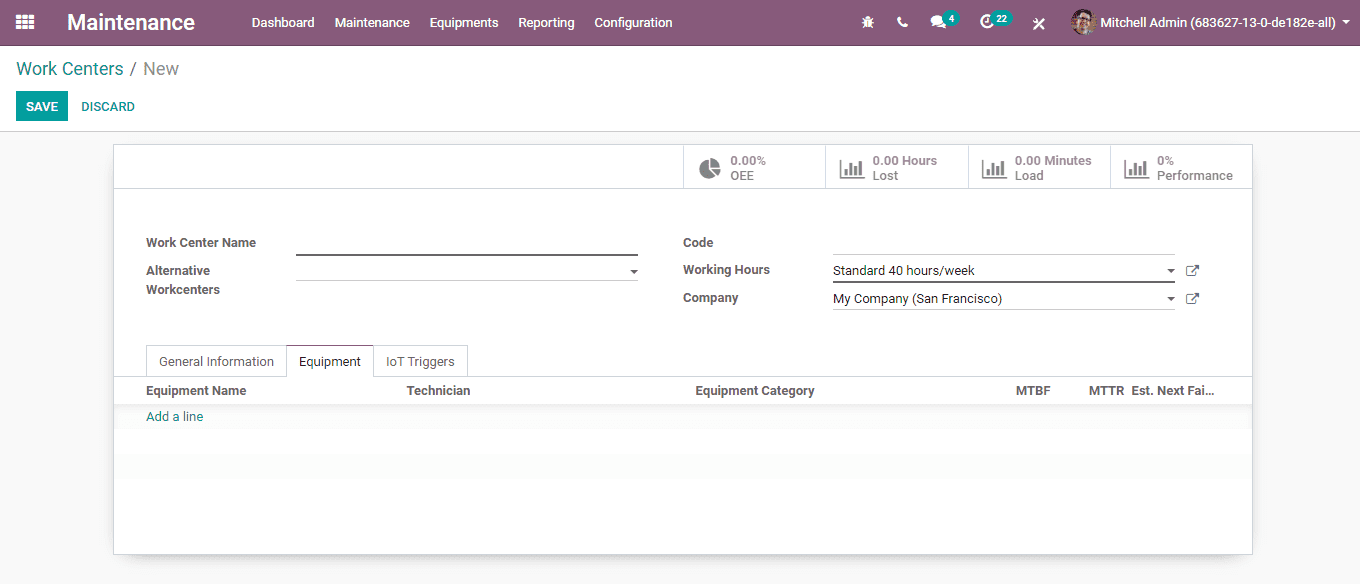

Creating a Maintenance Team

The main function of all Maintenance Management Systems is to observe the entire production and analyze the best practices in the particular field itself. For this, every company needed a specific maintenance team for it. Now let us look at how to create this maintenance team.

For this select, Maintenance -> Configuration -> Maintenance Teams -> Create

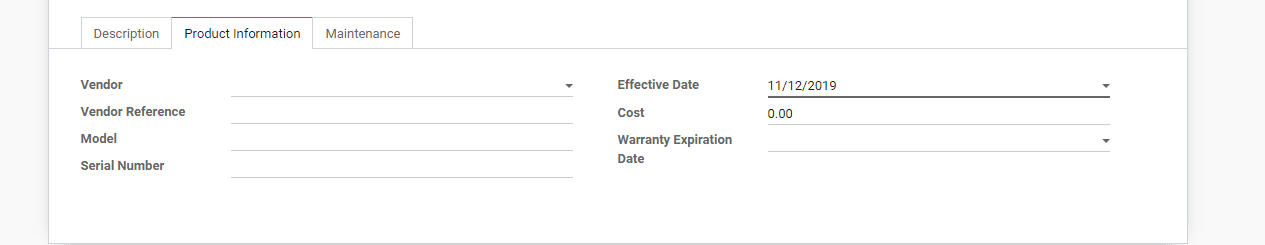

Under the option product information tab, you can add on the information concerning the equipment, for occurrence when was it bought. And under the maintenance tab information concerning those about the maintenance is displayed.

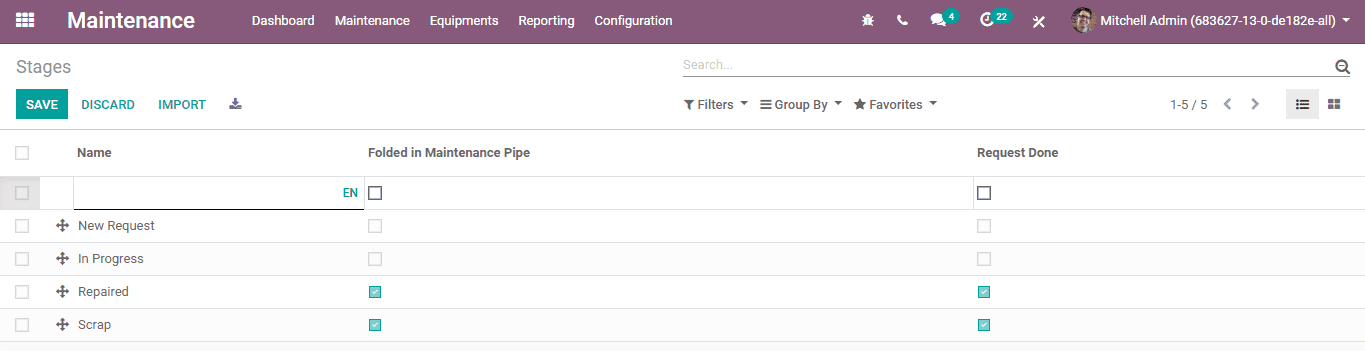

Creating Maintenance Stages

As your Maintenance is progressing you needed to create stages for the maintenance management, for this, Maintenance -> Configuration -> Maintenance Stages

So one can create a new Maintenance stage by clicking the Create Button.

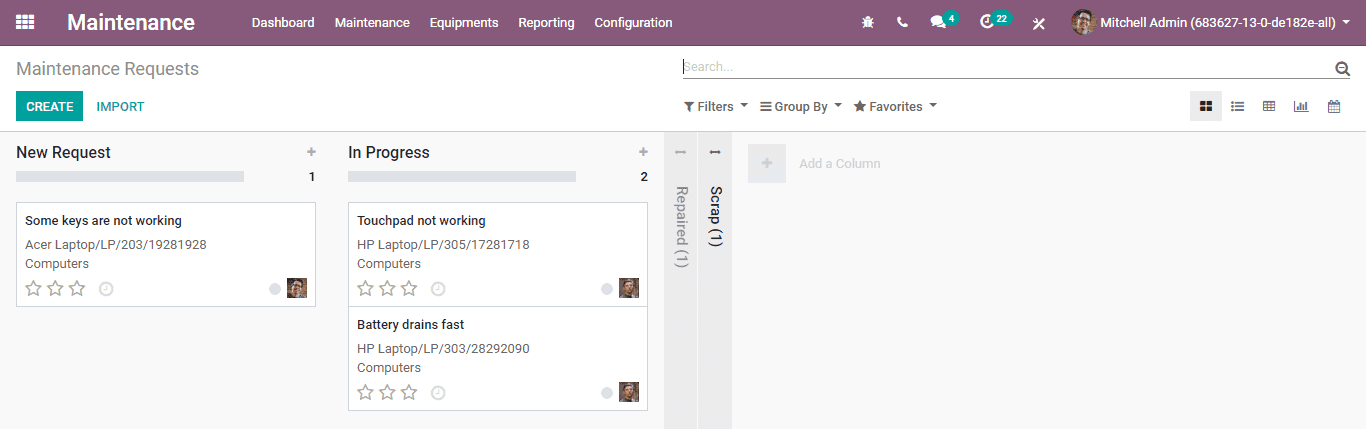

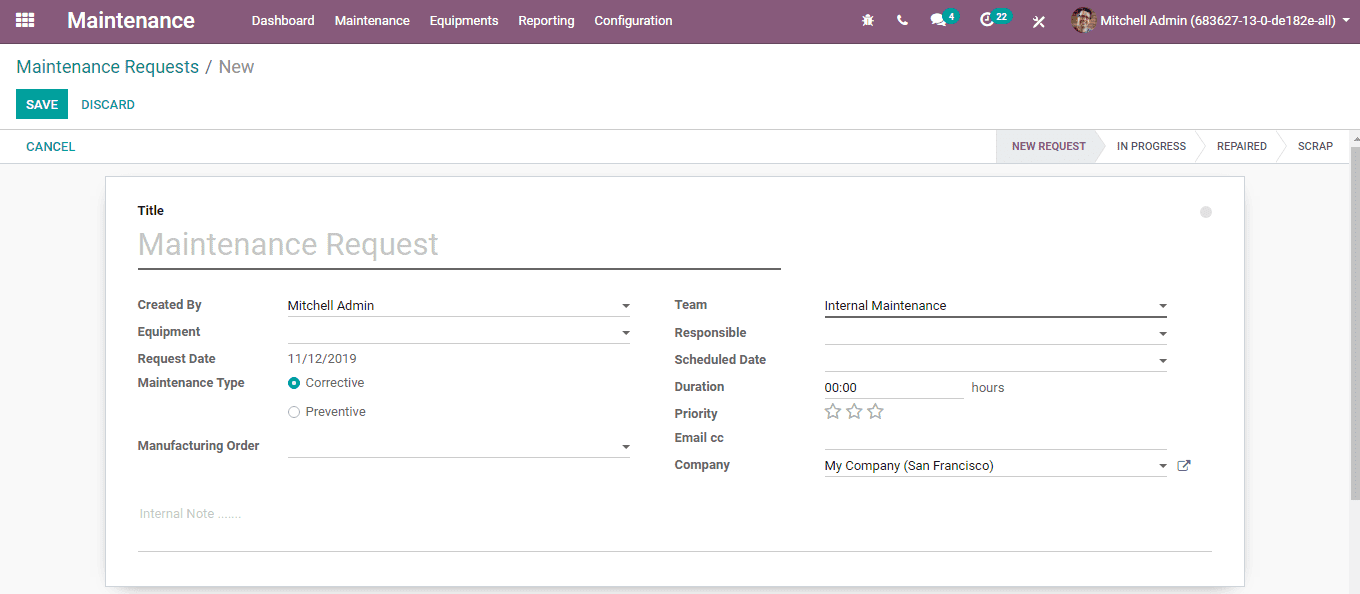

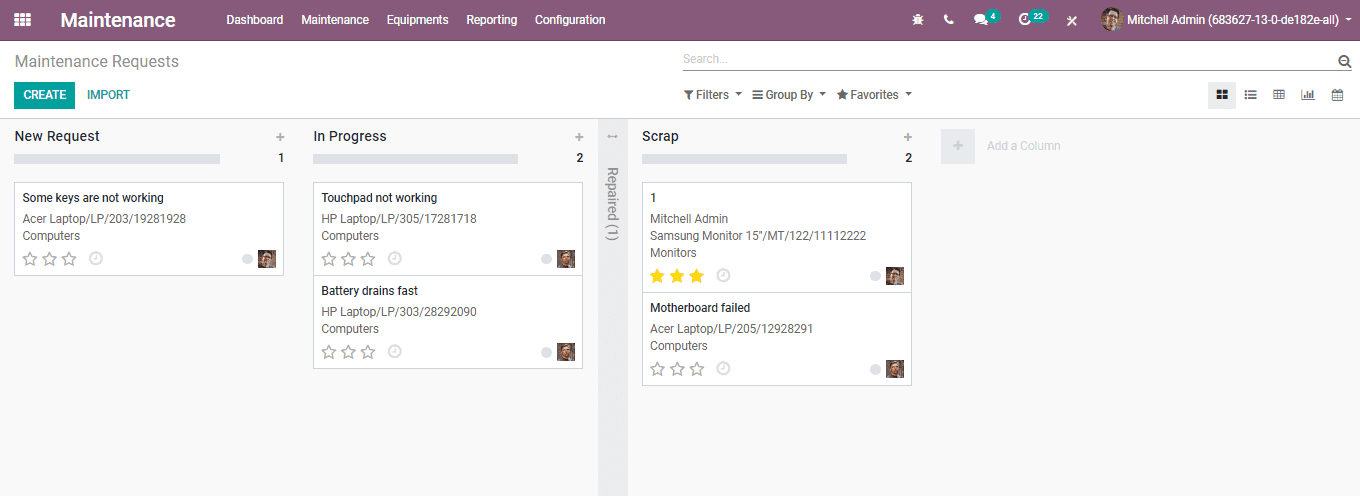

Creating Maintenance Request

Here you can see the ongoing maintenance request along with their status select, Maintenance -> Maintenance Request -> Create

Your new request will be created by clicking the Create Button

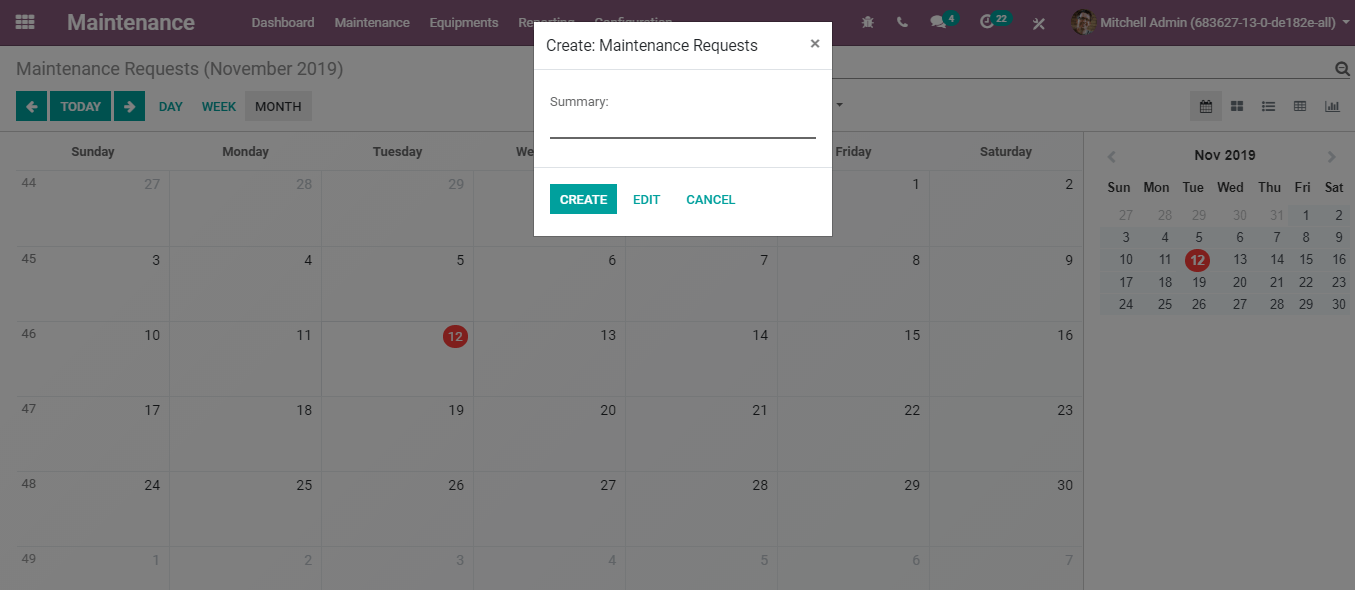

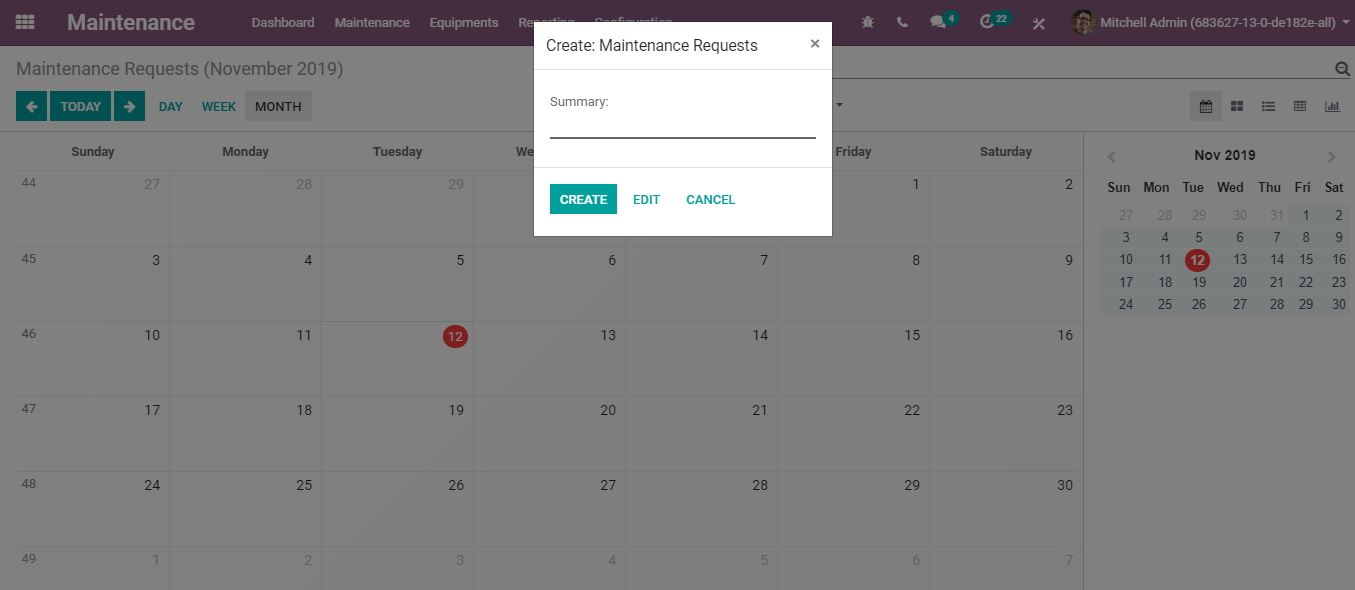

From the Calendar option also you can View or Create the Maintenance Request. For that, Go to Maintenance -> Maintenance Calendar

If you want to create a new maintenance request form you can click on to the edit button.

CORRECTIVE MAINTENANCE REQUEST

If the Maintenance is in the stage of progress, the state will move to Inprogress. Alongside if the equipment is said to be repaired the present state will automatically move to Repaired. Even if it is scrapped the state will be Scrap.

PREVENTIVE MAINTENANCE REQUEST

After the preventive maintenance request is saved, In the equipment, the very next preventive date will automatically set as the maintenance date. You can type preventive for creating a maintenance request.

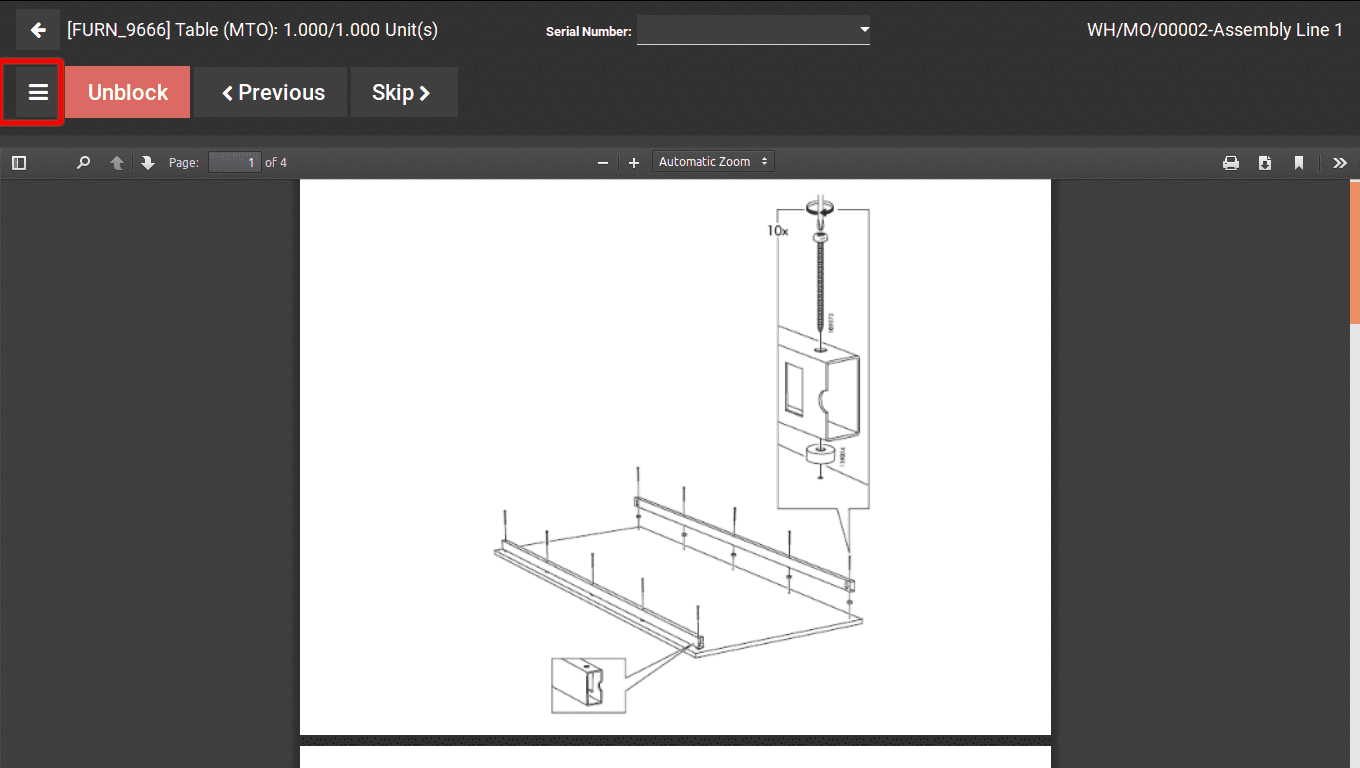

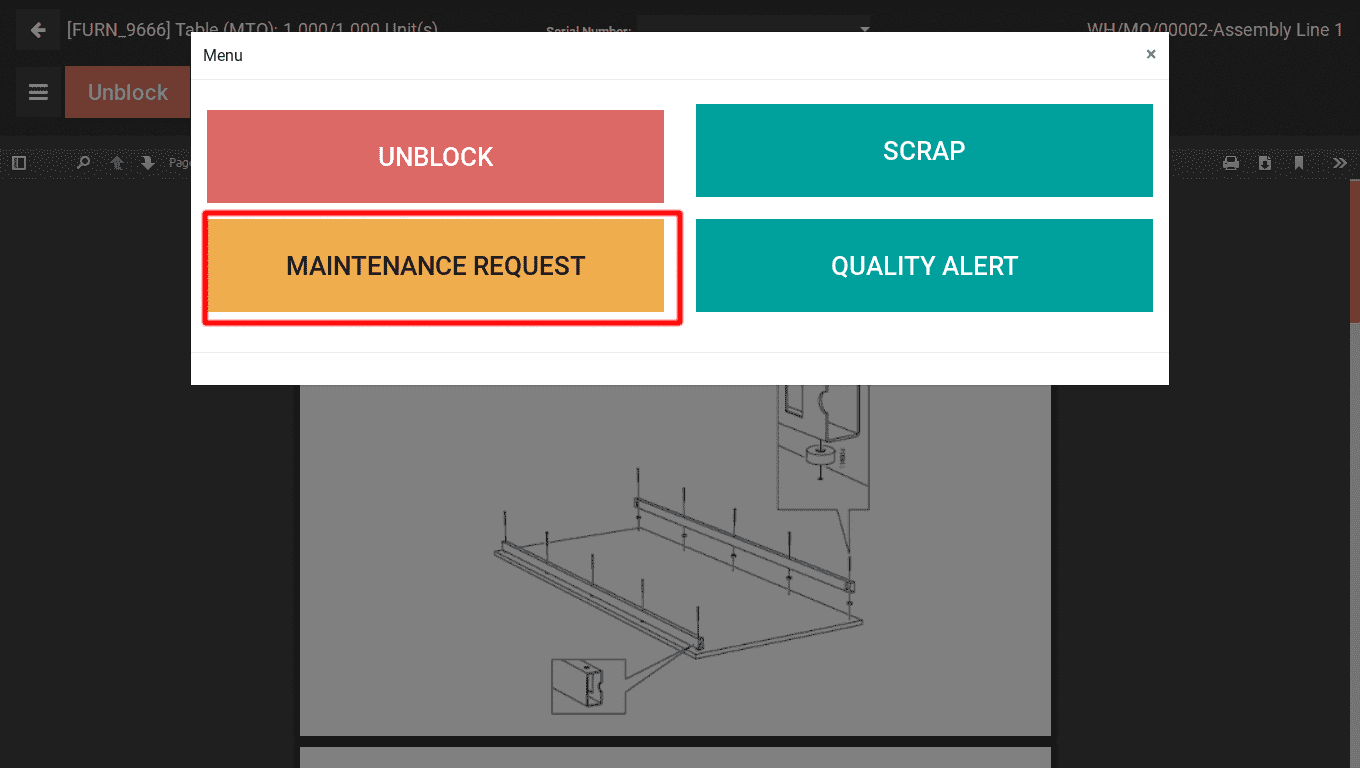

From work order and manufacturing order you can also make the maintenance request.

For this Go to Manufacturing Module. One can see the Maintenance Request button can be seen under the manufacturing order.

Click the menu bar as shown below to create maintenance requests from the wok orders even if the equipment used to fail while it is on run.

Thus to create a maintenance request this option helps.

For further details, you can also refer our odoo v13 book