Odoo 10 Enterprise version has some new modules like ‘Helpdesk ’, ‘Odoo studio’, ‘PLM’, ‘Quality Management’ and so on. Through this blog, we will cover some details about the main features of MRP module of Odoo 10 enterprise compared to Odoo 10 community. The main features are MPS, PLM, Quality Management, Maintenance.

Highlights of Odoo v10

– Just a couple of months back Odoo has launched its new version 10 with its new features. It has covered modules with more improvements in manufacturing module.

– Odoo 10 is a software suite where you will find “All Application under One Roof”.

Enterprise Edition v/s Community Edition

– Odoo 10 Enterprise version has some exclusive new modules to name a few are ‘Helpdesk ’, ‘Odoo studio’, ‘PLM’, ‘Quality Management’ and so on. Through this blog, we will cover some details about new enterprise module in MRP i.e., PLM, Quality Management etc..

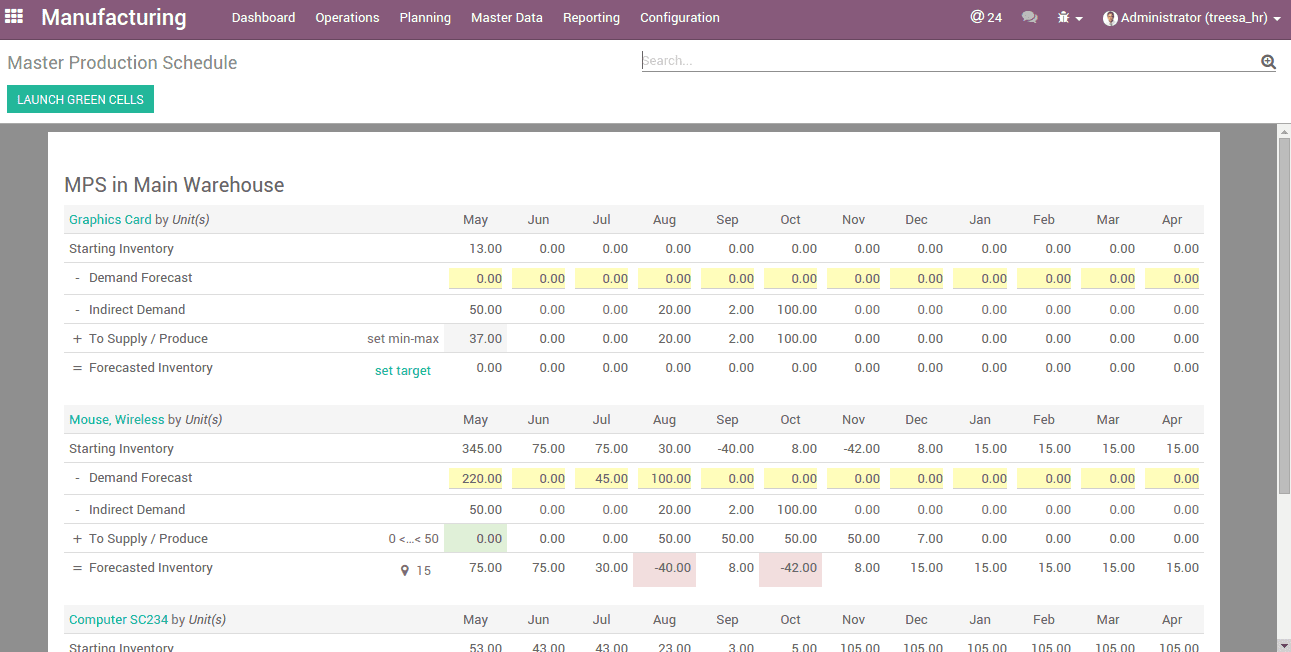

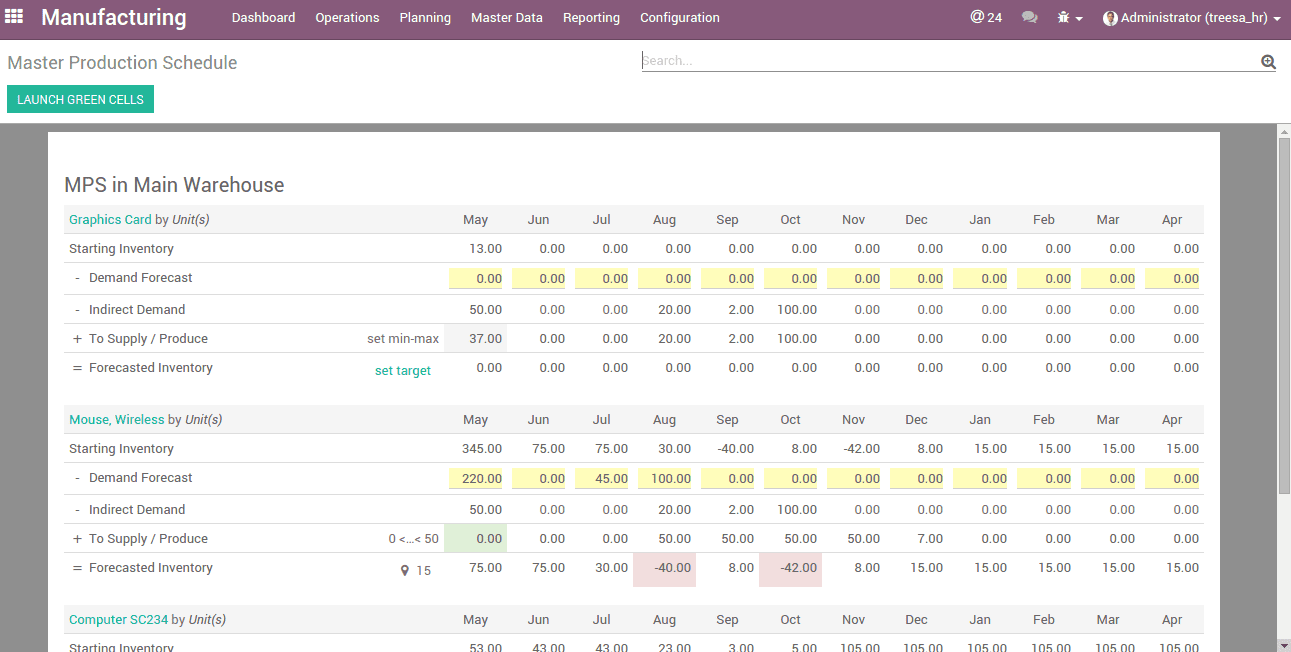

1.New Master Production Schedule to plan future manufacturing orders

Go to- Reporting > Master Production Schedule

Master Production Schedule (MPS)

– Master production scheduling plays an important role in the balancing of demand with supply.

– Satisfying customers according to the limits of the factory and the supplier’s base.

– MPS is used to know the number of the items that are to be produced, the planned inventories of raw materials, finished products, and parts, etc.

An effective MPS ultimately offers:

– Give production, planning, purchasing, and management the information to plan and control manufacturing

– Tie overall business planning and forecasting to detail operations

– Enable marketing to make legitimate delivery commitments to warehouses and customers

– Increase the efficiency and accuracy of a company’s manufacturing

– Rough cut capacity planning

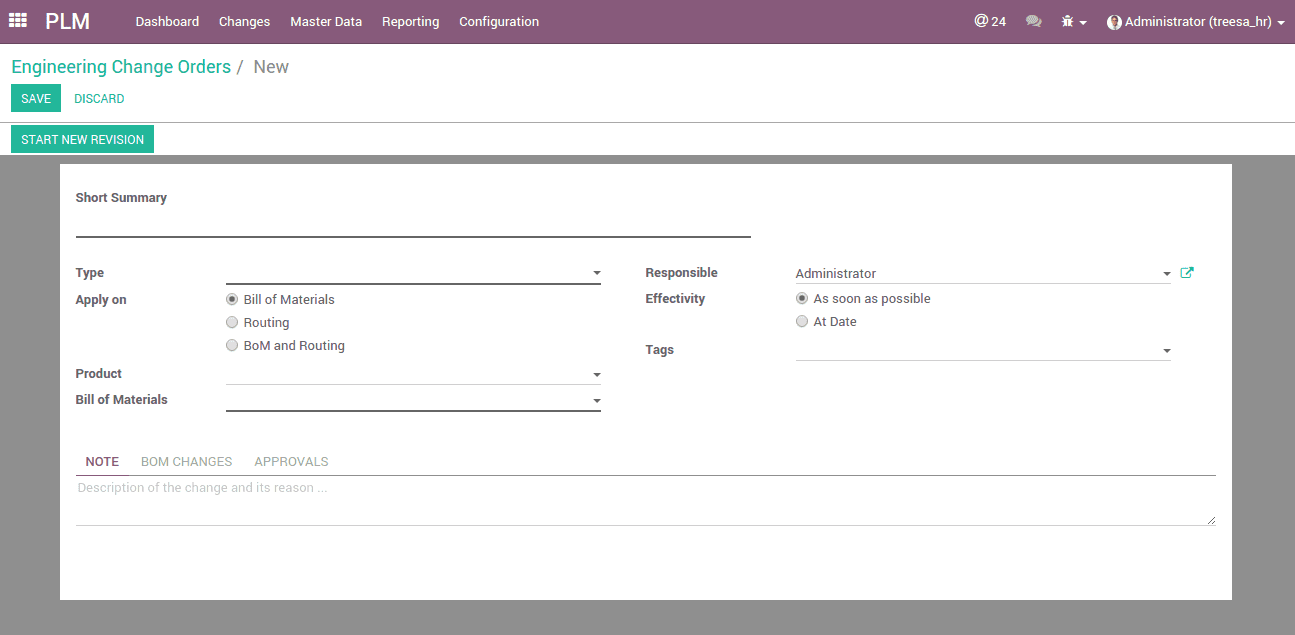

– The versioning of nomenclatures and routines s now supported and orchestrated by the new “Product Lifecycle Management” (PLM) module

– Here you can define the types of changes that can be applied, such as the replacement of a component or the changing a process.

-The related approval workflow can be also customized to see which users/departments are allowed to validate (or just comment) the change request.

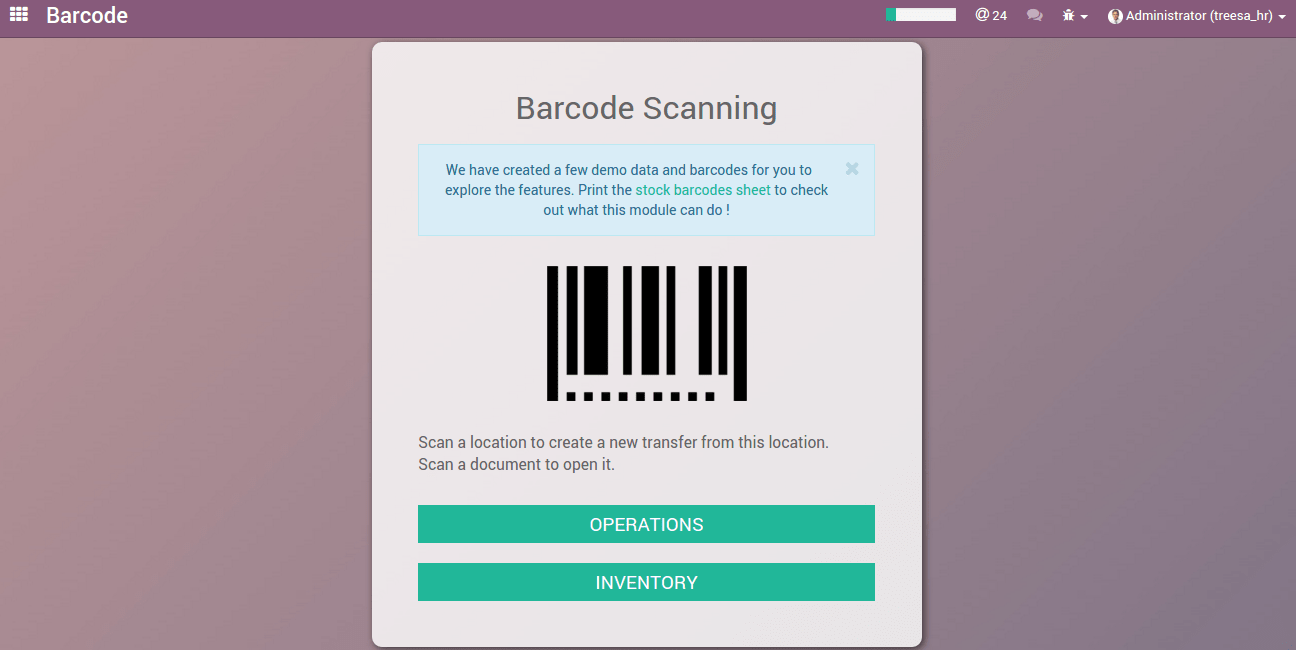

3. Barcodes and work centers

– The support of barcode scanners is extended beyond the simple scan of EAN13 products and lot numbers/series.

– The management of work orders is also facilitated.

– It is indeed expected to flash a barcode to start a work order, pause it and finish it.

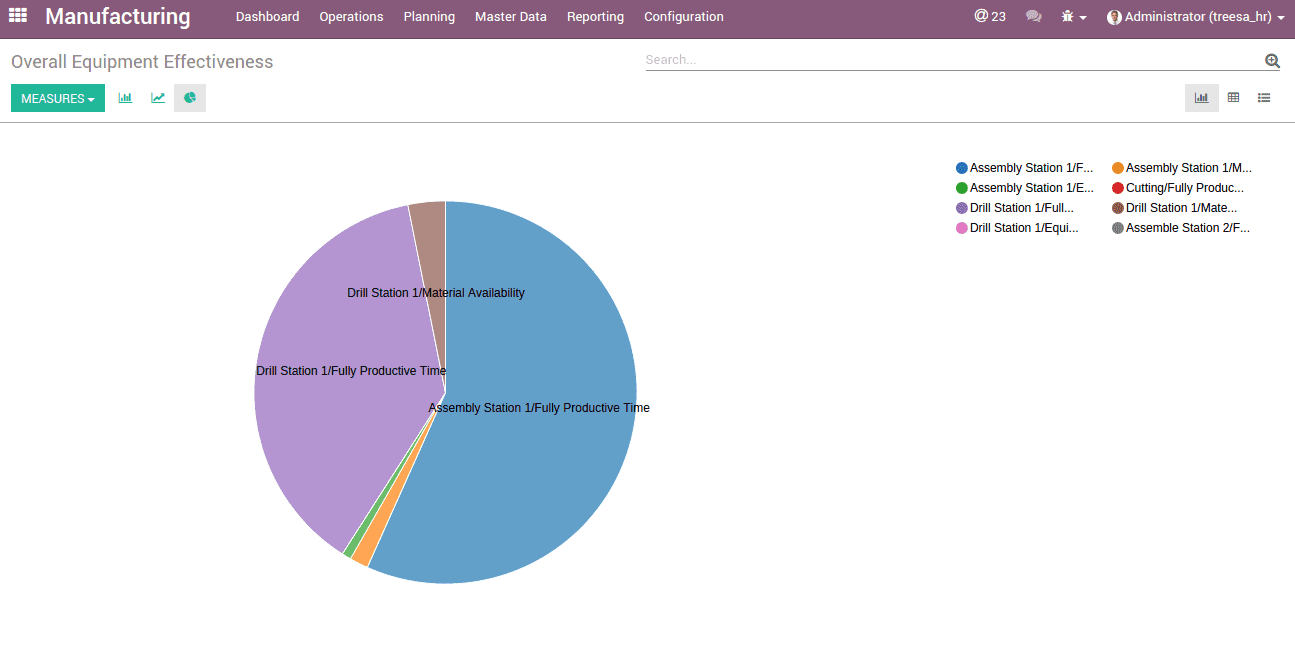

– Regarding work centers, you can track the percentage of efficiency and identify productivity losses (failure, decreased performance, lack of part).

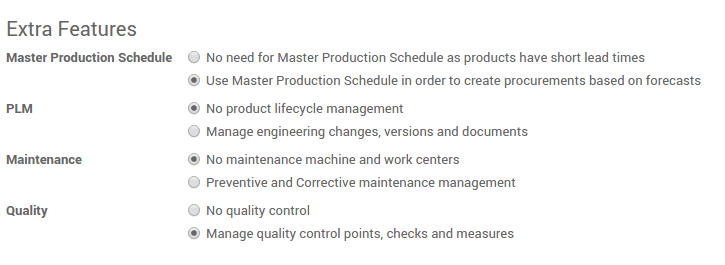

4. Manage quality control points, checks, and measures

You can go to Manufacturing > Configuration > Settings >Extra Features>Quality

– You can go to Apps>Quality and directly install it.

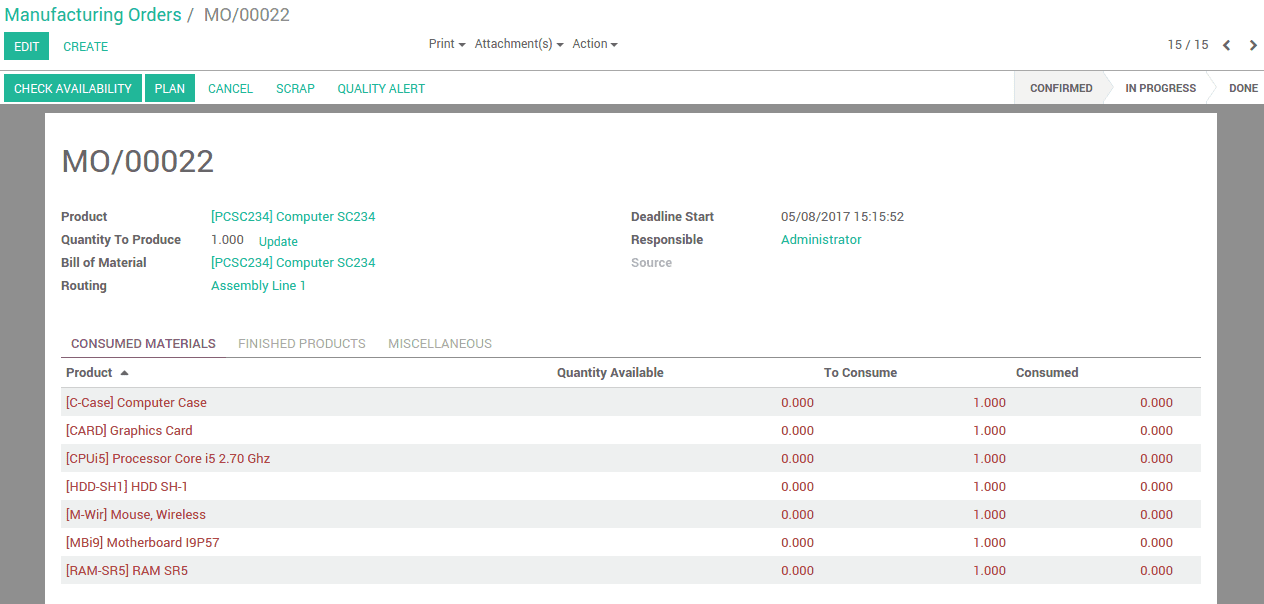

– Create a Manufacturing order for a product

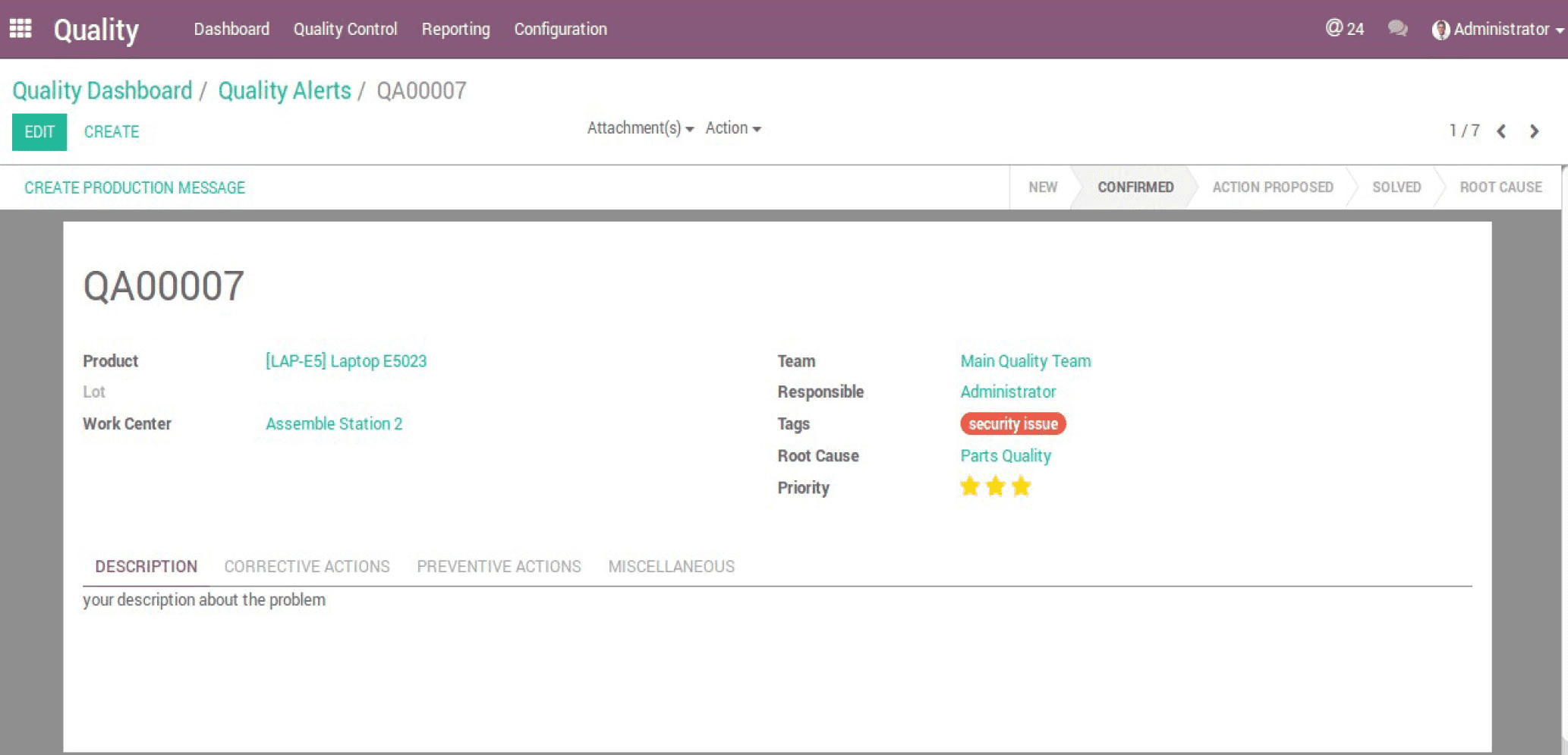

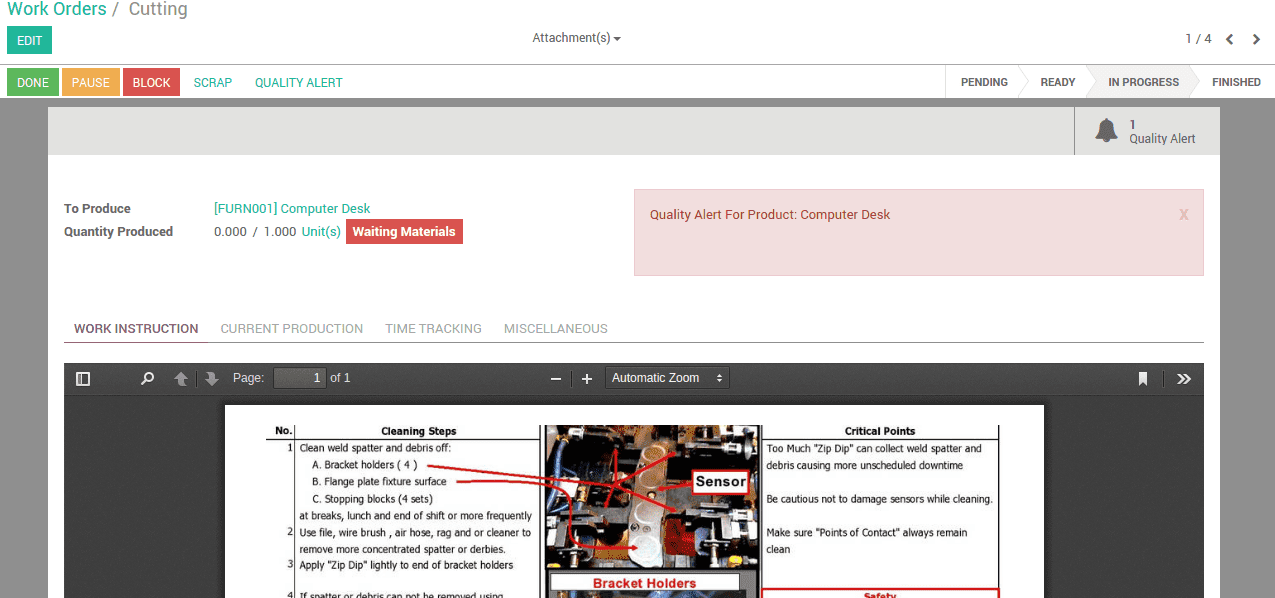

Click Quality Alert to create a quality alert

– You can also create quality alerts on work orders.

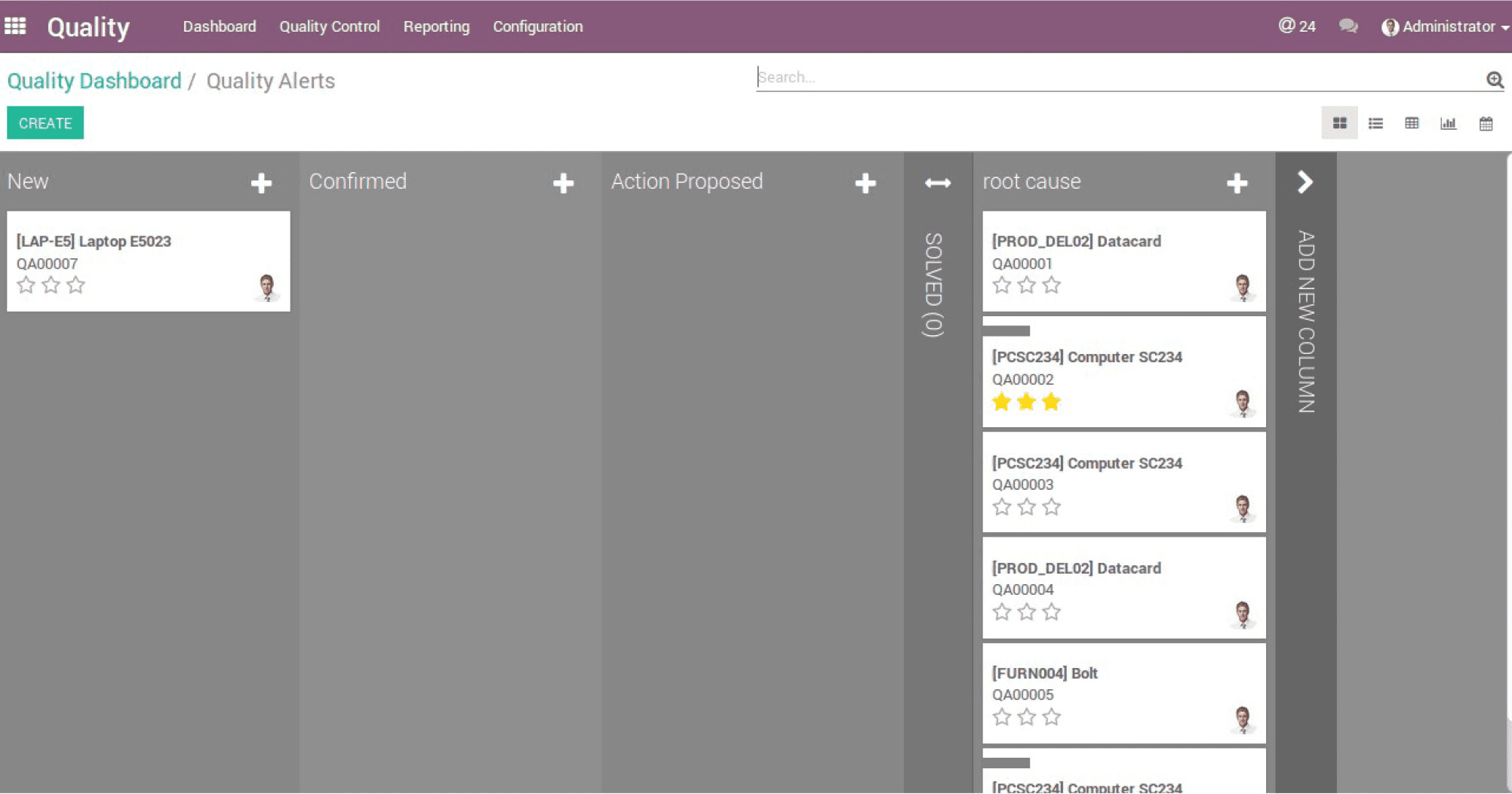

Go to Quality>Quality Dashboard>Quality Alerts.

– You can see all the alerts related to that Quality team.

– You can manage your own workflow on the quality dashboard.

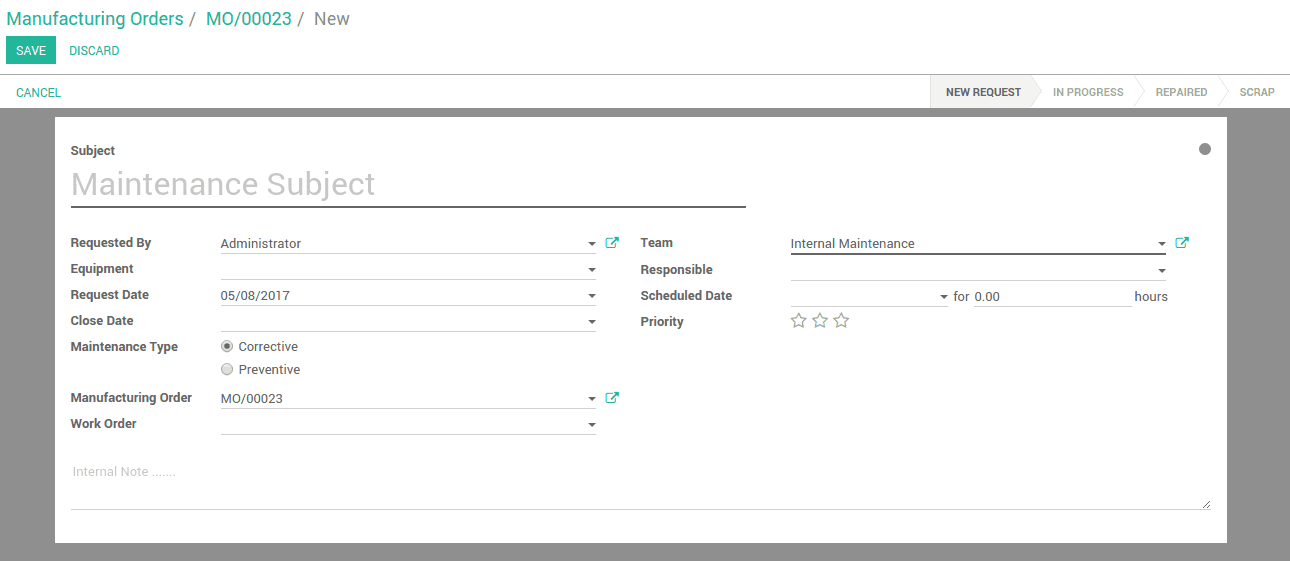

5. Preventive and Corrective maintenance management

– Discover the new machines maintenance application for the manufacturing sector.

– Show how to manage preventive and real-time maintenance of your material.

– Help you plan preventive maintenance, including mean time between failure (MTBF), mean time to repair (MTTR), and expected next failure date

– Track maintenance requests using the kanban view.

– Use the maintenance calendar to organize and plan activities.

Corrective maintenance

– Defined as a maintenance task performed to identify, isolate, and rectify a fault so that the failed equipment, machine, or asset can be restored to an operational condition within the tolerances or limits established for in-service operations.

– Corrective maintenance is maintenance that is carried out after failure detection and

– Aimed at restoring an asset to a condition in which it can perform its intended function.

Preventive maintenance(PM)

– Maintenance, including tests, measurements, adjustments, and parts replacement, performed specifically to prevent faults from occurring.

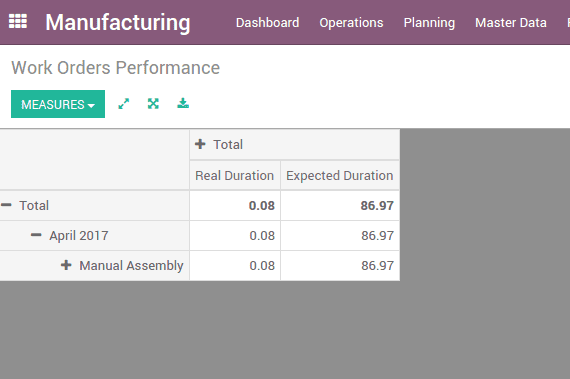

6.Reports

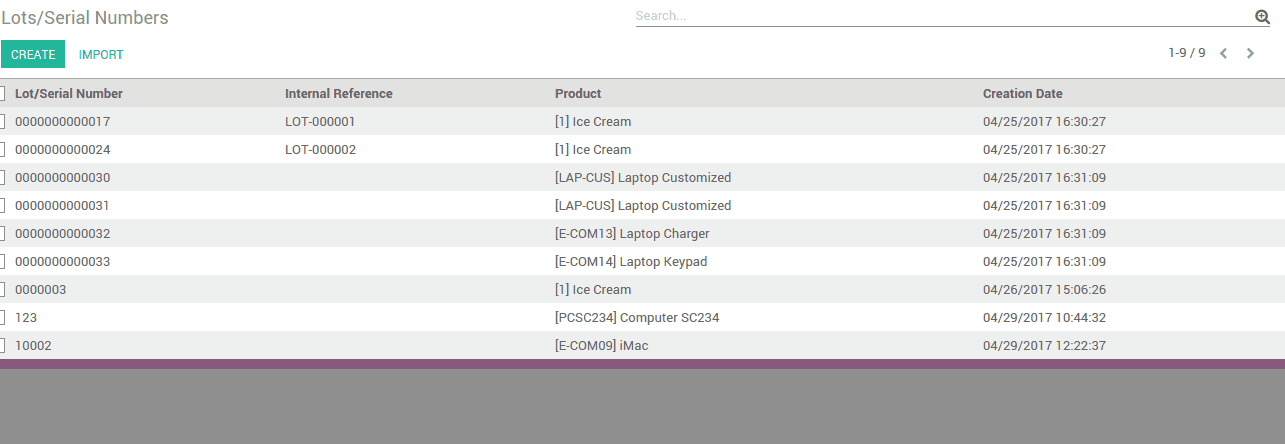

Lots/Serial Numbers

Master Production Schedule

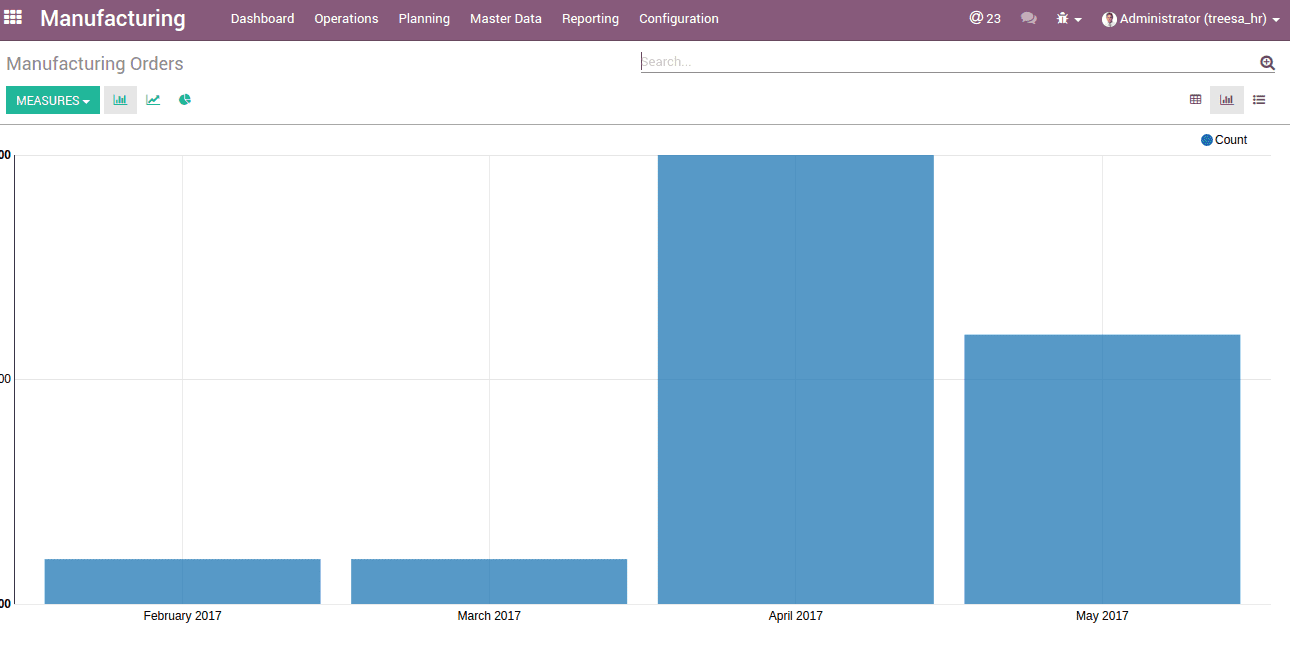

Manufacturing Orders