Planning production and managing production are two important parts of any manufacturing business. These processes help a business to manage all activities in an efficient way and ensure the effective completion of all the works.

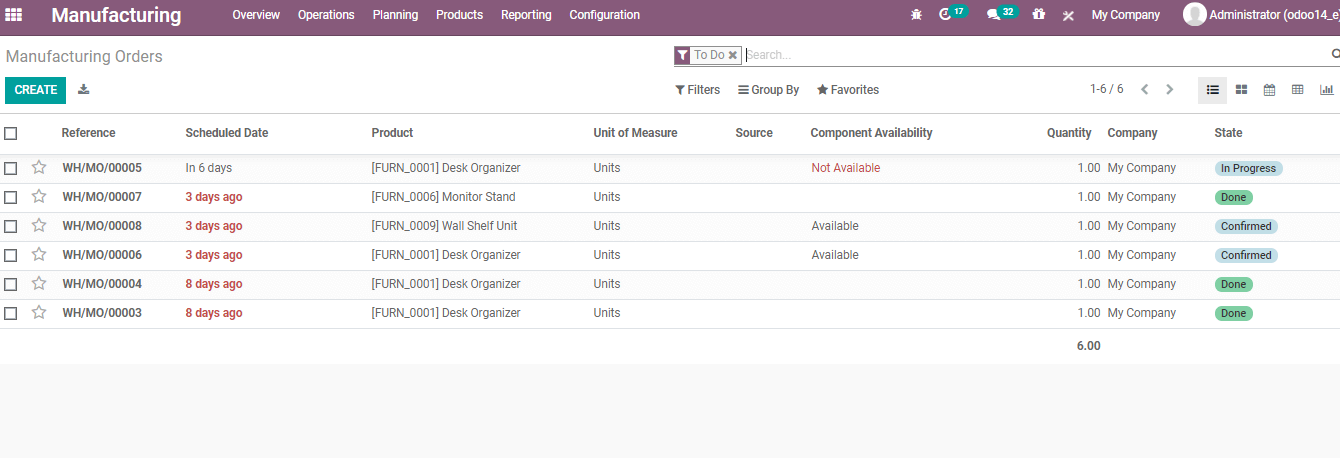

In a manufacturing unit, the works are mostly carried out based on manufacturing order. On receiving the manufacturing order, the user can plan the work order and production using Odoo. Odoo helps to list out all manufacturing orders based on deadline and priority.

For ensuring a systematic production, a user will have to plan a work order and work center. In this blog, we can take a look at how Odoo helps to manage production by planning production. This enables the user to locate and set work centers for the production activity. In this blog, we can take a look at how Odoo helps to manage production by planning production. As we can start production only after receiving a manufacturing order, we can start the planning process after confirming the manufacturing order.

A user can start production with the Odoo after seeing the manufacturing order which has to be considered for the process on a priority basis. To start production Go to Manufacturing> Operations> Manufacturing Orders> Work Orders. Work Orders helps the user to view all ongoing manufacturing orders.

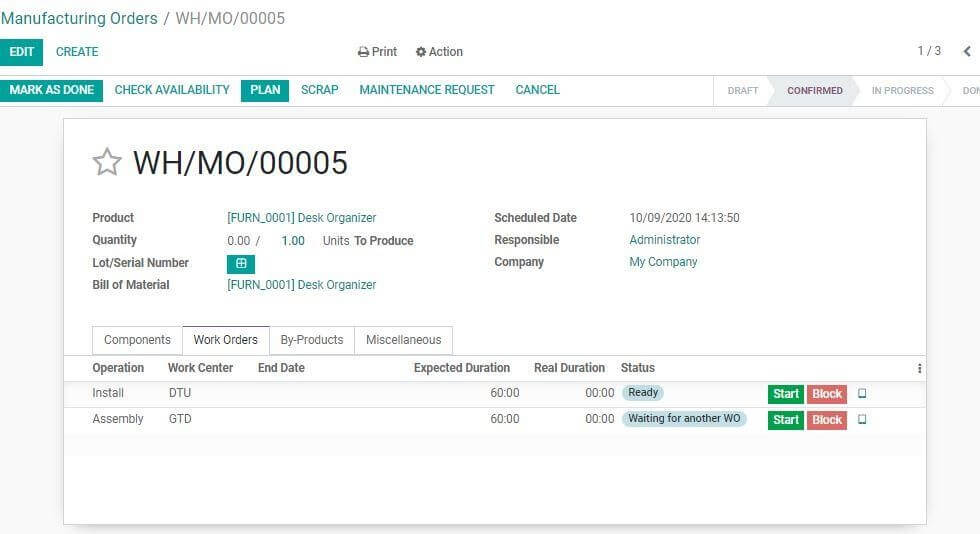

In the next phase, the user can select the manufacturing order which you want to select. The selection is easy and can be done by just clicking on the manufacturing order.

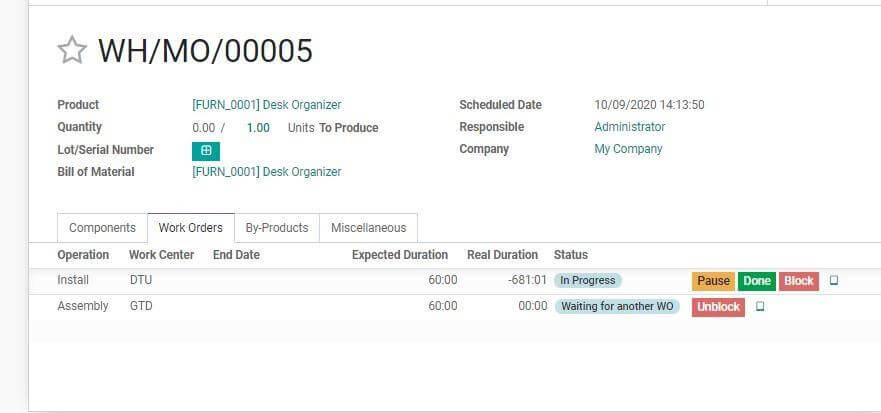

On opening the MO, you will find details like the name of the product, quantity to be produced, bill of materials, the person responsible, scheduled date, etc.Besides, four tabs can also be viewed here. IT helps to view the components, work order, by-products, and miscellaneous.

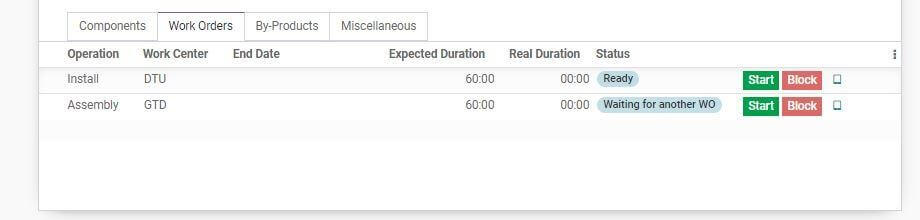

To start production the user will have to choose the Work Order tab.

On clicking it, the user will get the activities involved in the production process and the work center details. The expected duration to complete the work and the end date can be viewed here. The user can also find the status of the work order. If the work can be completed at one work center itself only one work center will be listed here. In the above-given case, we have two work centers to complete the production process. As the status of the work order is ready we can start the production process just by clicking the start button.

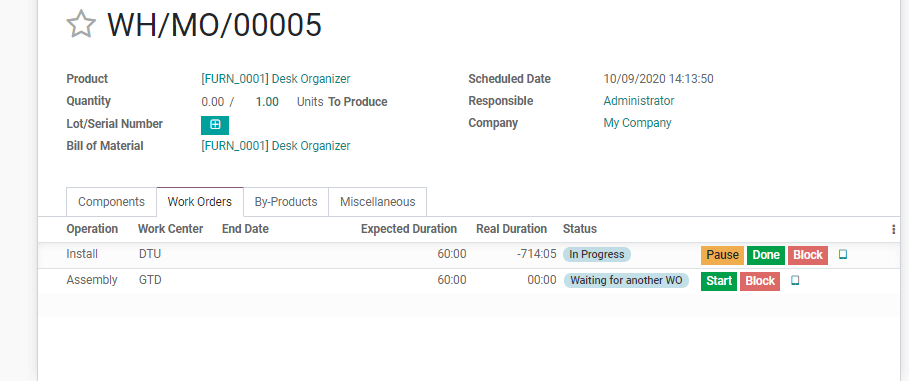

On clicking the Start button the status of the Work order changes to In Progress. The user can either click the Done button to mark the process as completed or use the Block button to stop the production.

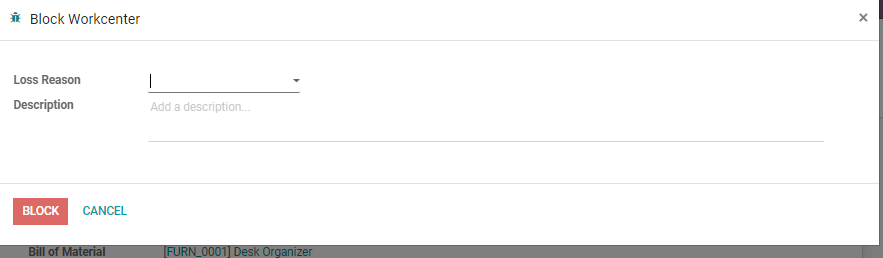

What happens if you choose the Block Button? You will get a pop-up window. This window gives you an option to give the detail for blocking the production. In this window, the reason will be named as LOSS Reason. The user can also give details here.

After completing the process, the user can click the block button for blocking. Once you block the process, you get a new option for work order- unblock. This helps the user to unblock the production process and resume the activity.

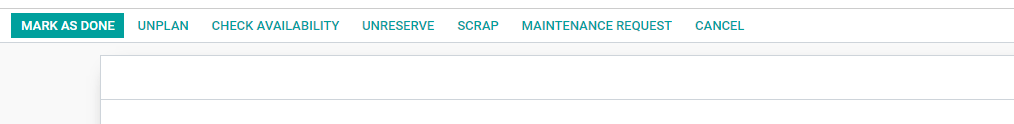

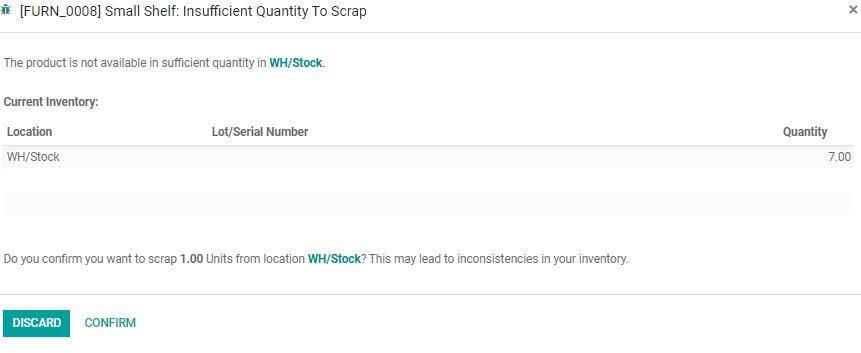

You can also mark a blocked product as scrap. This can be done by clicking the Scrap button.

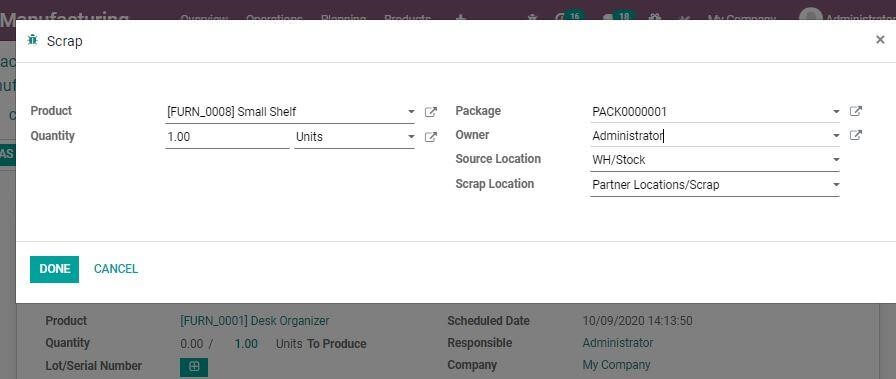

On doing this the user will get a pop-up window

In the pop-up window, the user can add the details of the product, quantity, details of the owner, source location, and the scrap location. After filling in the details click Done.

Confirm the process and then return to MO

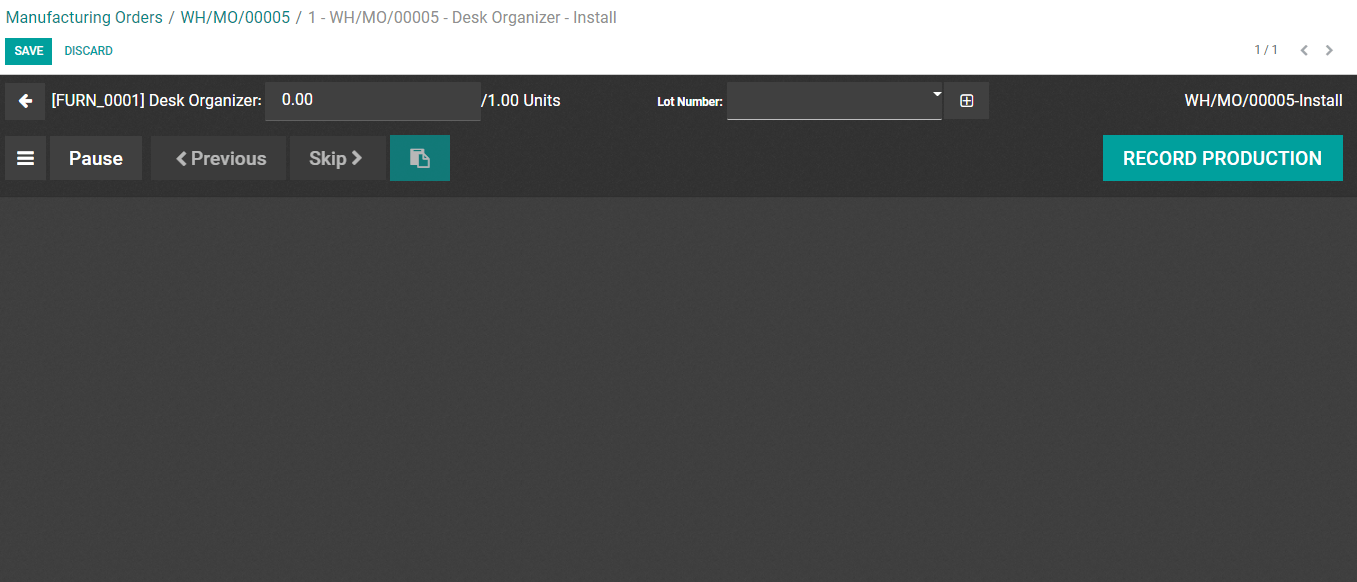

While managing production, you can find one more option on the right-hand side of the Start button. On clicking on the icon the user will be taken to an external link. This link can be used to access the instructions for production if we have set any such instructions already.

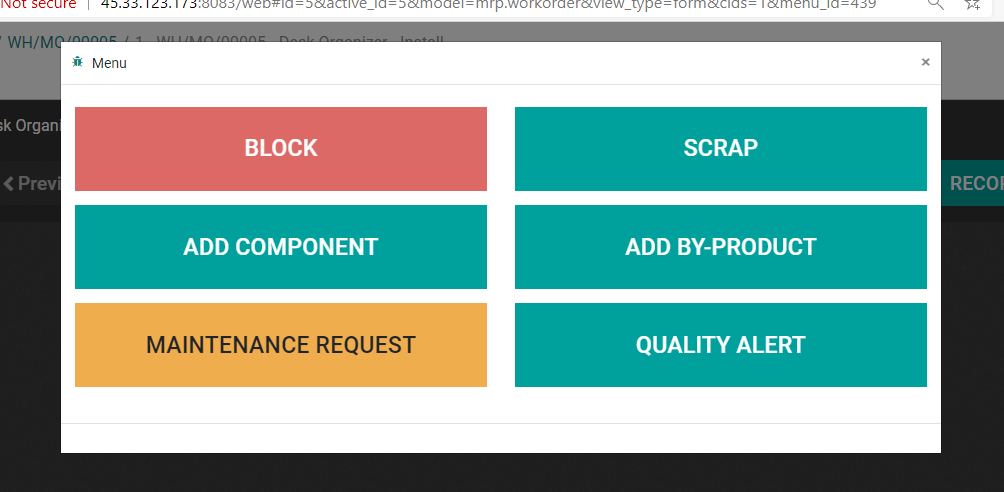

The user can easily add production instructions here. Besides, adding components, blocking, scrapping and other activities can also be completed here. The user can click on the menu tab if you want to access the options listed here.

After completing the process the user can click the Done button. This is used to stop the production process. This way, Odoo 14 can help a user to manage products using manufacturing orders.

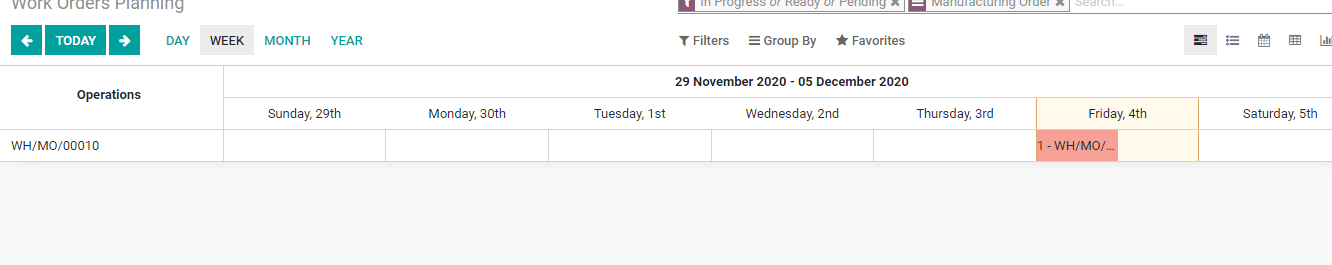

Plan Production using the calendar

Under Planning Tab, the user can manage production activities. This can be done by clicking Plan by work order by going to Manufacturing> Planning> Work Order> Planning by Production

The user can view all work orders for a day, week, month, or year here. This helps to efficiently plan the work order and manage the workforce and time.