Manufacturing a product involves multiple tasks, including listing the bill of materials, assigning work centers and routes, product assembly, quality check, maintenance, etc. All the various stages and processes should be planned and executed properly, or else, it may result in production errors and as a result, money loss to the company. Every single aspect of production should be planned, monitored, and evaluated properly to prevent any errors during production. Odoo’s manufacturing module helps you to set, track and analyze the various manufacturing process without any confusion. Its high customizability allows you to map all the specialized operations your company requires to manufacture a product.

Watch this video to learn more about Manufacturing Order Management in Odoo 13

Let’s see how a manufacturing order is created in Odoo 13.

To create a manufacturing order in Odoo firstly, one has to set up a Bill of Material for the product.

Go to Manufacturing > Master Data > Bills of Materials

In the newly appeared window, click on the create button present on the top left corner.

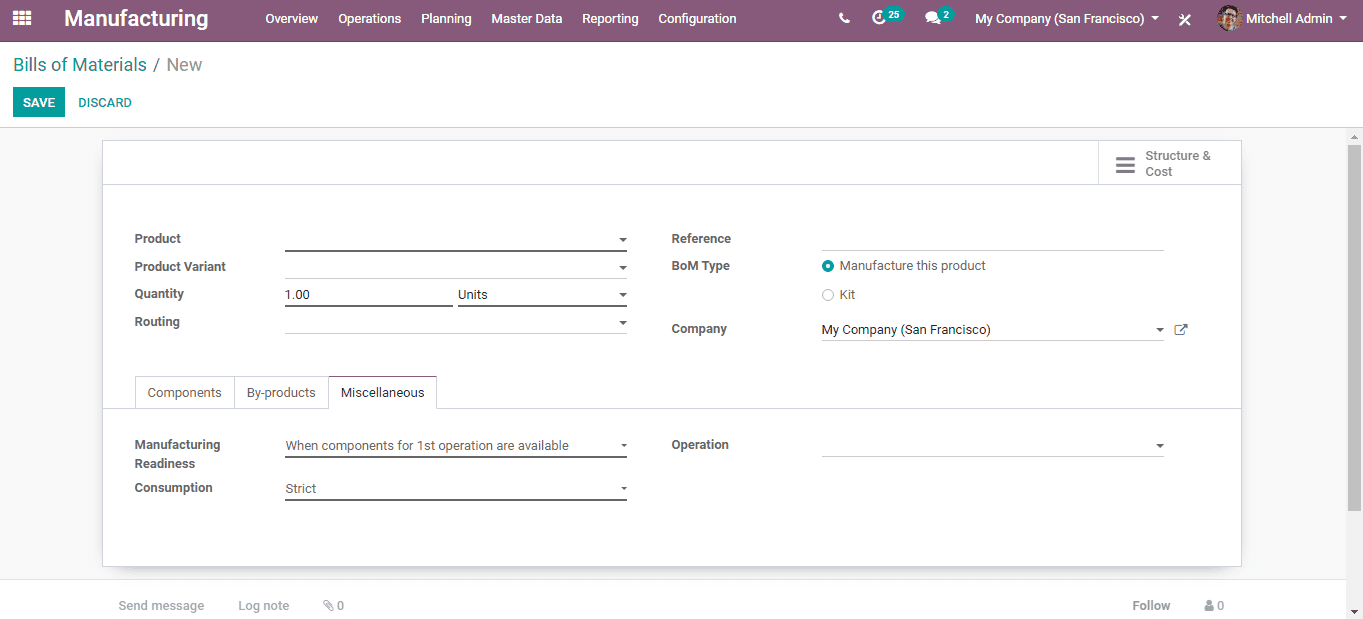

The picture depicted above is the form to create a bill of materials. There are various fields to be filled here;

Product: Select the product to which the bill of material is being created, from the product list.

Product variant: Select the specific variant of the product (if any) to which the bill of material is being created.

Quantity: The specific quantity of the product to which this bill of materials applies.

Routing: Select the routing of the manufacturing of the product.

Reference: Enter any reference note here if needed.

BoM Type: There are two options for the bill of materials;

Manufacture this product: The product with this bill of materials will only be manufactured.

Kit: The product with this bill of materials will not be produced. This option is for creating a product kit that is ready to be sold to the customer or for semi-finished products.

Company: Select the company if you have multiple companies.

Now, under the ‘Components’ tab, select all the components to be listed in this bill of materials.

Under the ‘Byproducts’ tab, enter the by-products details if any is produced during the manufacturing process.

Under the ‘Miscellaneous’ tab, there are 3 fields to be filled;

1. Manufacturing readiness: Here, you can either select ‘When components for the first operation are available’ or when ‘All components are available’

2. Consumption: You can select this as either ‘Strict’ or ‘Flexible’ With strict you cannot add eliminate a component while manufacturing and flexible allows this.

3. Operation: Select the nature of operation with this bill of material.

Now, click ‘Save’ and now you have successfully created a Bill of Material

In order to create a Manufacturing order;

Go to Manufacturing > Operations > Manufacturing orders

Click the ‘Create’ button on the newly appeared window. And a form like the one above appears. Select the Product and Quantity to Produce. Also, select the Bill of Materials from the list and all the tabs below will automatically be filled with the details from the BoM.

Select the Deadline, Planned Date, Responsible (Preferable authority), and Company.

Click ‘Save’ and a new Manufacturing order is created.

Once created, you can proceed with work orders to manufacturing the product. Also, there are options to ‘Plan’ and to send a ‘Maintenance Request’ during production requests in it.