Odoo, an Open Source ERP has flourished with a lot of tools for a complex business management platform to fulfill it’s business needs. Unlike other ERP, Odoo covers wide range modules like Sales, Purchase, Manufacturing, Inventory, Accounting, Project management, etc. Every module is related to one another and hence provides an integrated platform.

Odoo Manufacturing module helps the end-user to manage with the details of production, deal Bill of Materials, handle work center and routes plan to purchase orders, track work orders and so on. To take advantage of this feature, one needs to install the ‘Manufacturing’ module from Odoo Apps.

The manufacturing of the product may not take a single stage. Thus working methodology can be defined in two ways. Either one can simply follow the default stages and complete production or their available options to assign work centers and routes for the production of the product.

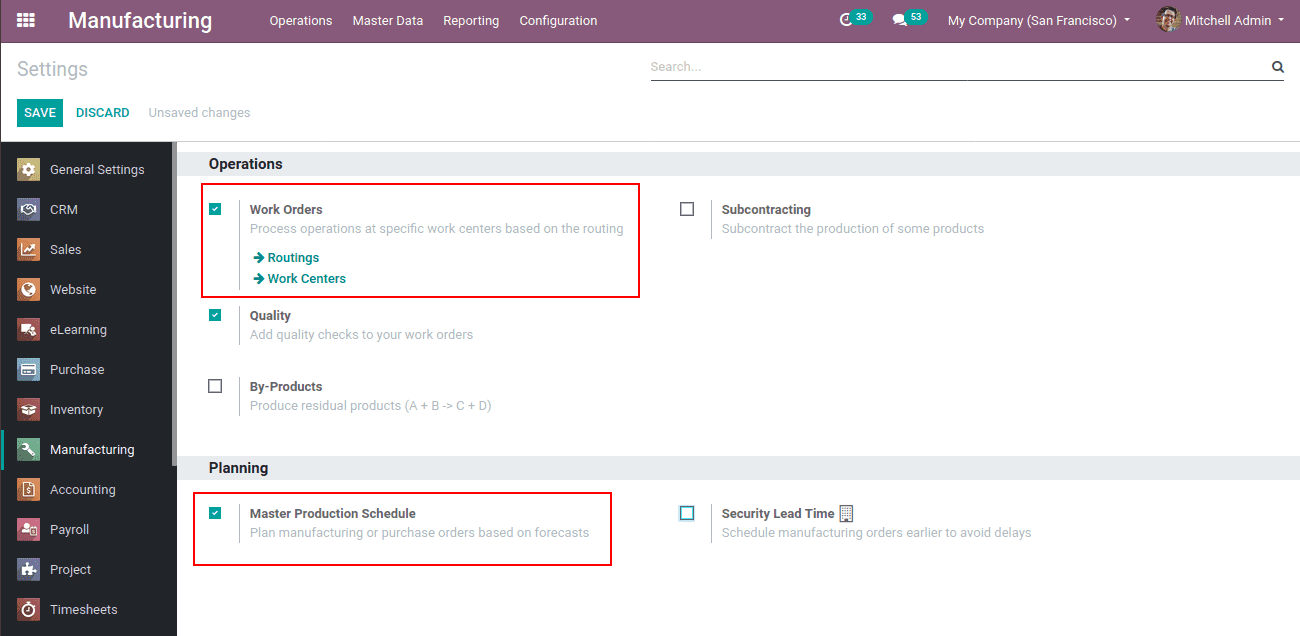

To avail, this feature should enable routing and planning features that come under settings of the manufacturing module.

Configuration > Setting > Operations > Work Orders

There you can create and use Routes and work Centers.

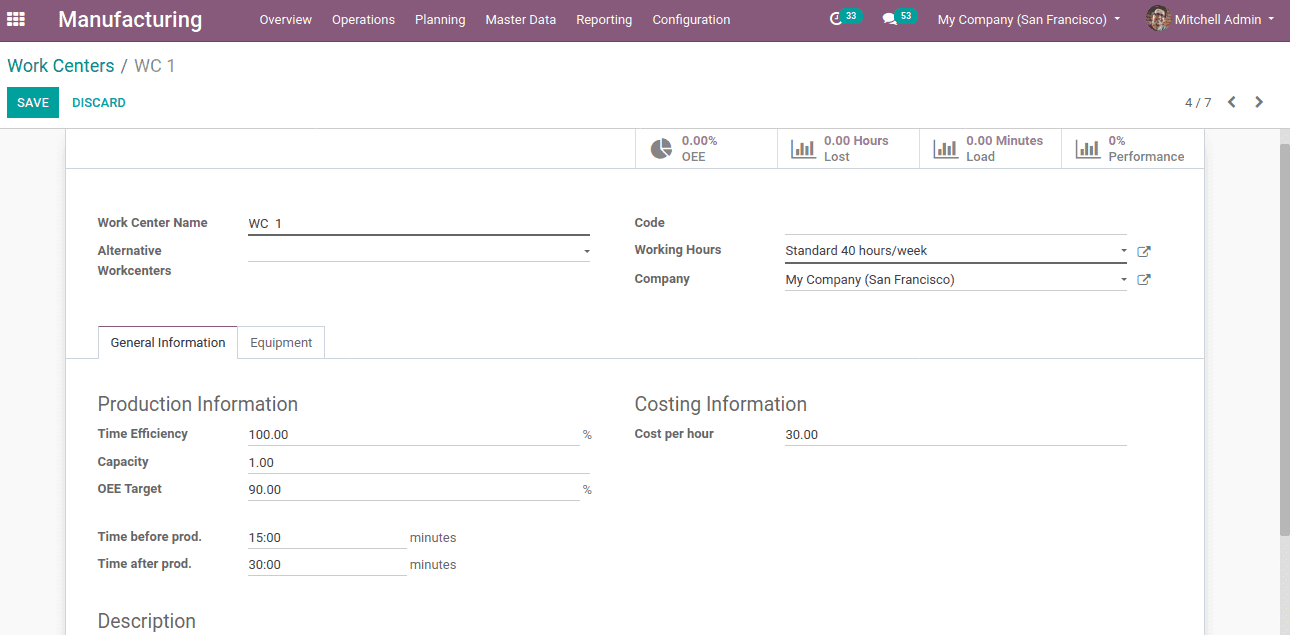

Work centers are the physical space in the manufacturing company where different kinds of manufacturing procedures take place. To create required work centers

Manufacturing > Master Data > Work centers > Create

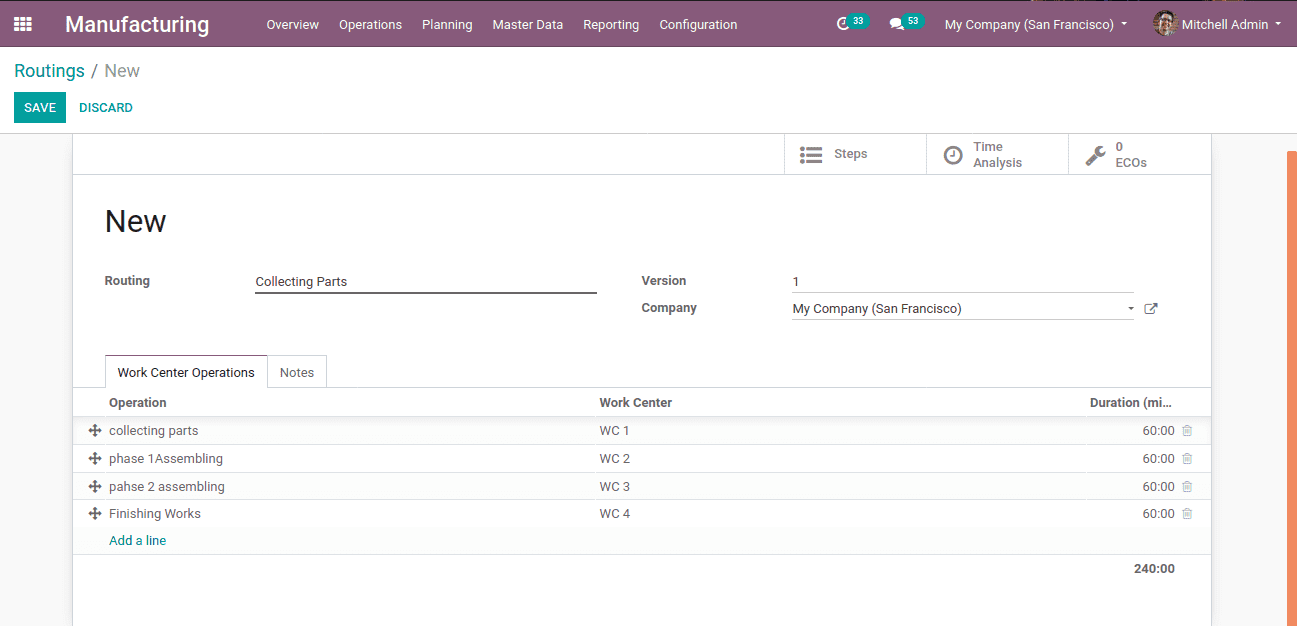

Routes refer to the path to be followed by each component to transform in raw input to the desired final product. When a route is specified the production orders will be executed through work orders, else everything executed in the production order. To create routes,

Manufacturing > Master Data > Routing> Create

Thus work centers and routes are configured. Now let’s see how it works with the Bill of Materials.

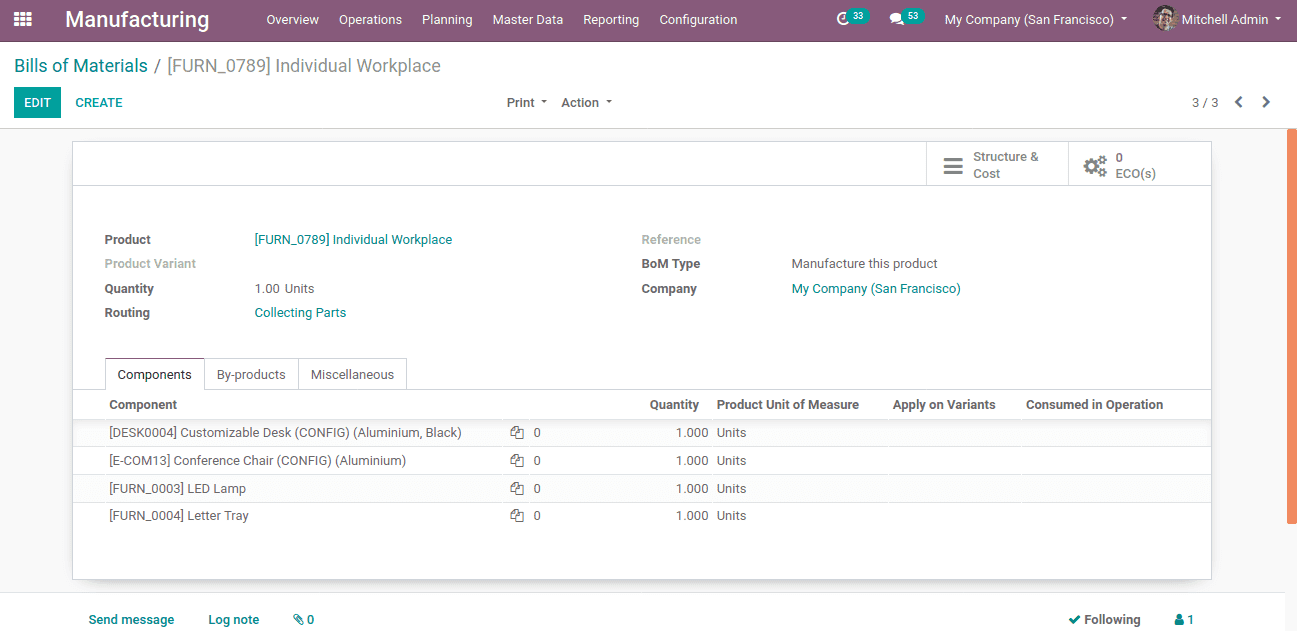

Bill Of Materials is a document that defines a complete list of materials required for manufacturing a product. BoM clearly defines the quantity required, routing and individual steps to be followed to carry the manufacturing process.

For creating BoM select, Manufacturing > Master Data > Bill of Materials.

In the Bill of Materials, you can add the product name, Quantity, BoM Type, Route, etc. In the routing, the field specifies the created route and components also.

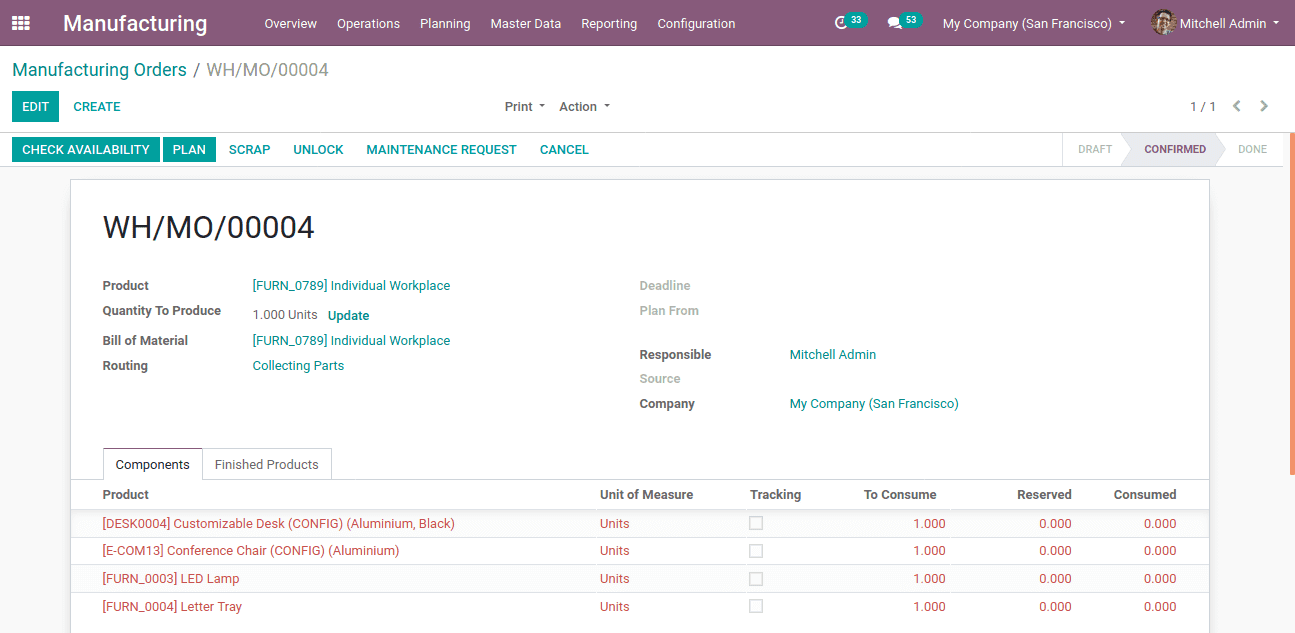

Make a manufacturing order for your product by, Manufacturing > Operations > Manufacturing Orders.

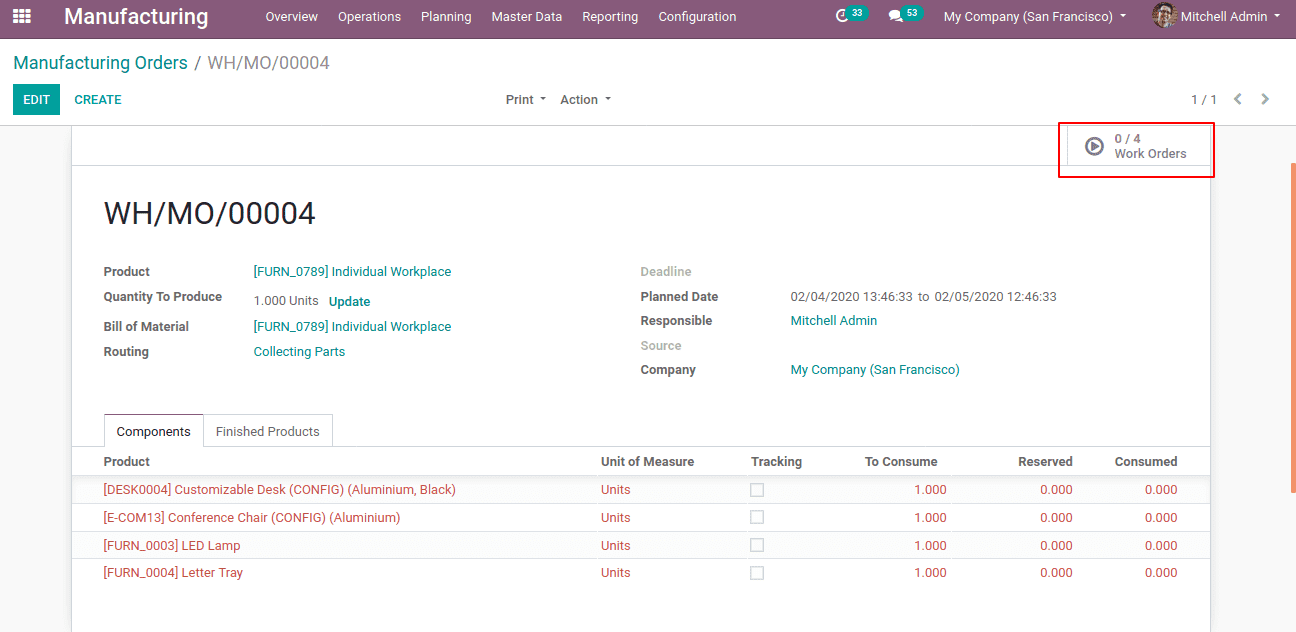

We have already created four work center operations like collecting parts, phase 1 & phase 2 assembling and finishing. Each operation complete one at a time. When clicking on the PLAN, you can see a smart button’ Work Orders’ appears at the right corner.

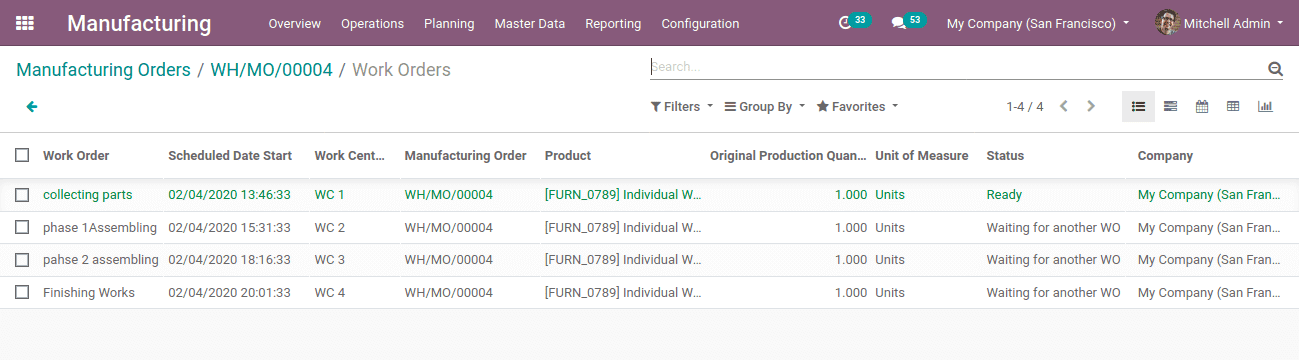

You can find the work orders as shown below.

Initially the first work order is in the ready state while others are in waiting, state. The second work order process only after the first one is completed.

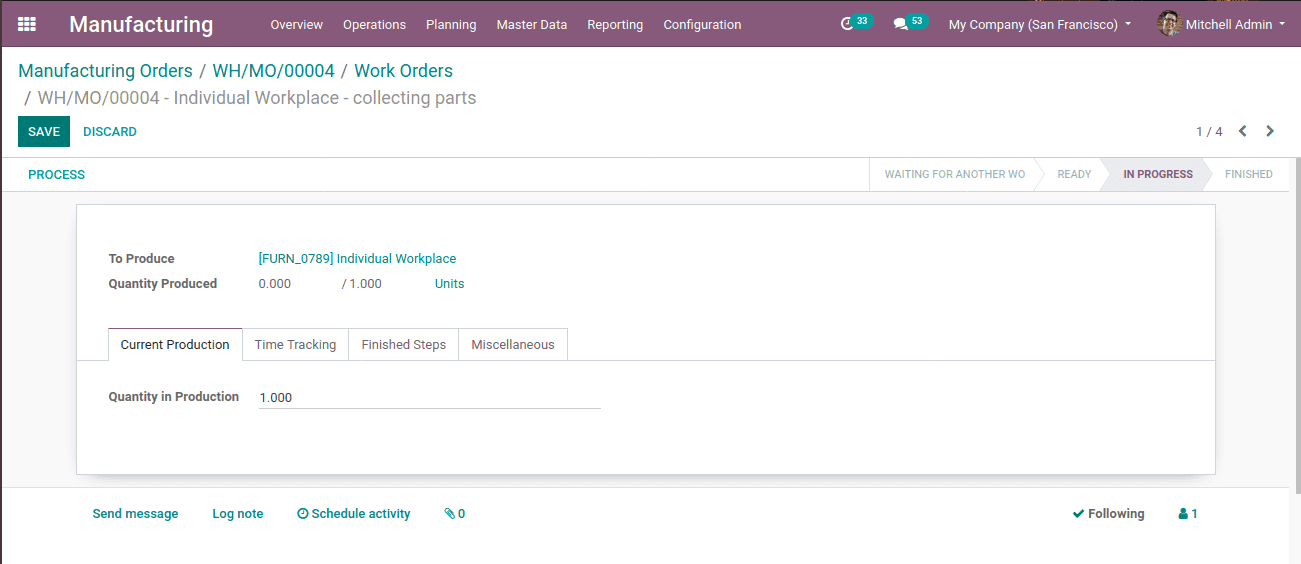

While clicking on PROCESS, it leads to another page which is shown below.

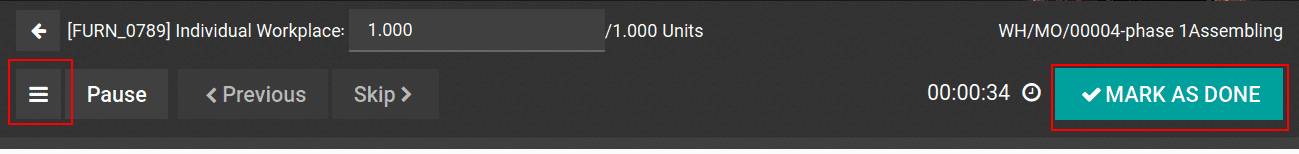

Click on MARK AS DONE if the operation is completed and one can find the time taken for that work order.

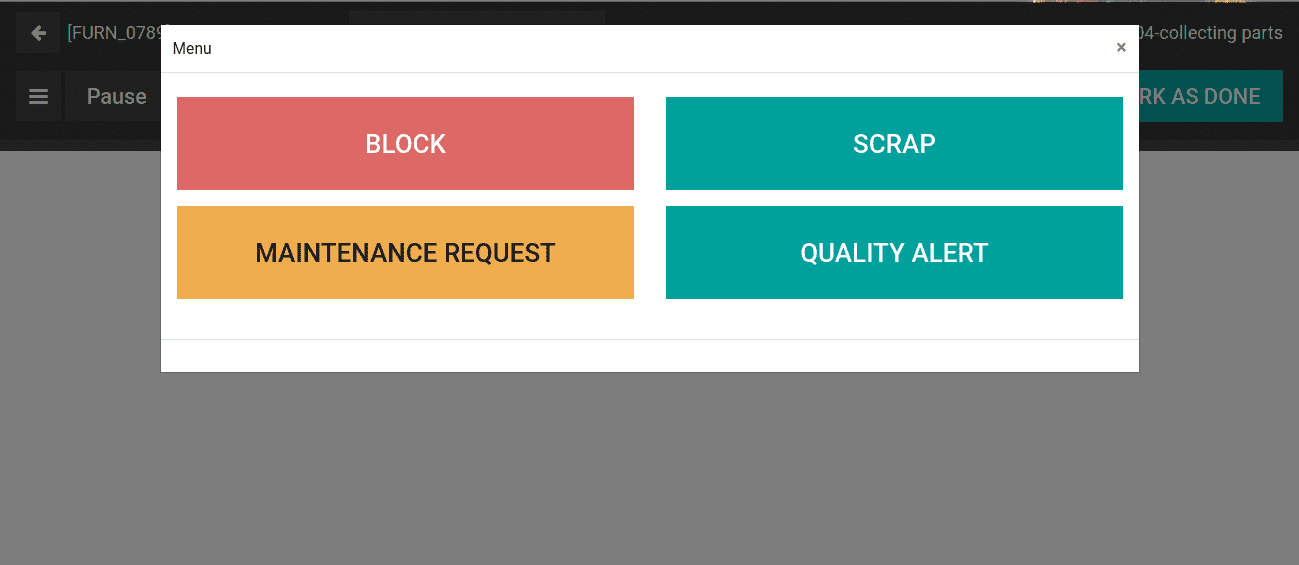

Also one can block the work center operation, scrap products, create quality alerts and maintenance requests.

On successful completion of the first work order, the second work order came to the ready state and later others too. This is how multi-step production works in Odoo 13.