Manufacturing is the process of creating goods with the help of raw materials, labour, machinery, and other support systems. Manufacturing a product is really difficult and complex. Because work orders, production, maintenance of equipment, repair, and quality checks are all part of the manufacturing process.

Manufacturing may work in a variety of ways for different types of businesses. It is influenced by the products, the company’s attitude, resources etc. Mainly there are 5 Types of Manufacturing.

Repetitive Manufacturing

Create a similar product on an assembly line and repeat the procedure. The automotive, Electronics, and Semiconductor sectors have all employed this strategy.

Discrete Manufacturing

Manufacturing takes place on an assembly line in this case as well, but the ultimate output is different. Industries like Computers and laptops use this technology.

Job Shop Manufacturing

Instead of an assembly line, work centers are used in this production area. When the product arrives at their work facility, each employee adds something to it. For the aerospace & defense industry, it is used in fighter jets and rockets.

Continuous Process Manufacturing

Large order numbers of similar products are produced in this manufacturing. Instead of solid material, gasses, liquids, powders, and slurries are used as raw materials. This approach was employed in the pharmaceutical, fertilizers, and oil refining sectors.

Batch Process Manufacturing

In this process, a number of batches are created, and in between each batch, the equipment is cleaned, and the next batch is prepared. It is used in the manufacturing process of ketchup, mayonnaise, etc.

Food manufacturing is a difficult task. There are several issues, such as product expiration, storage, damage or scrap, and so on, which we must handle.

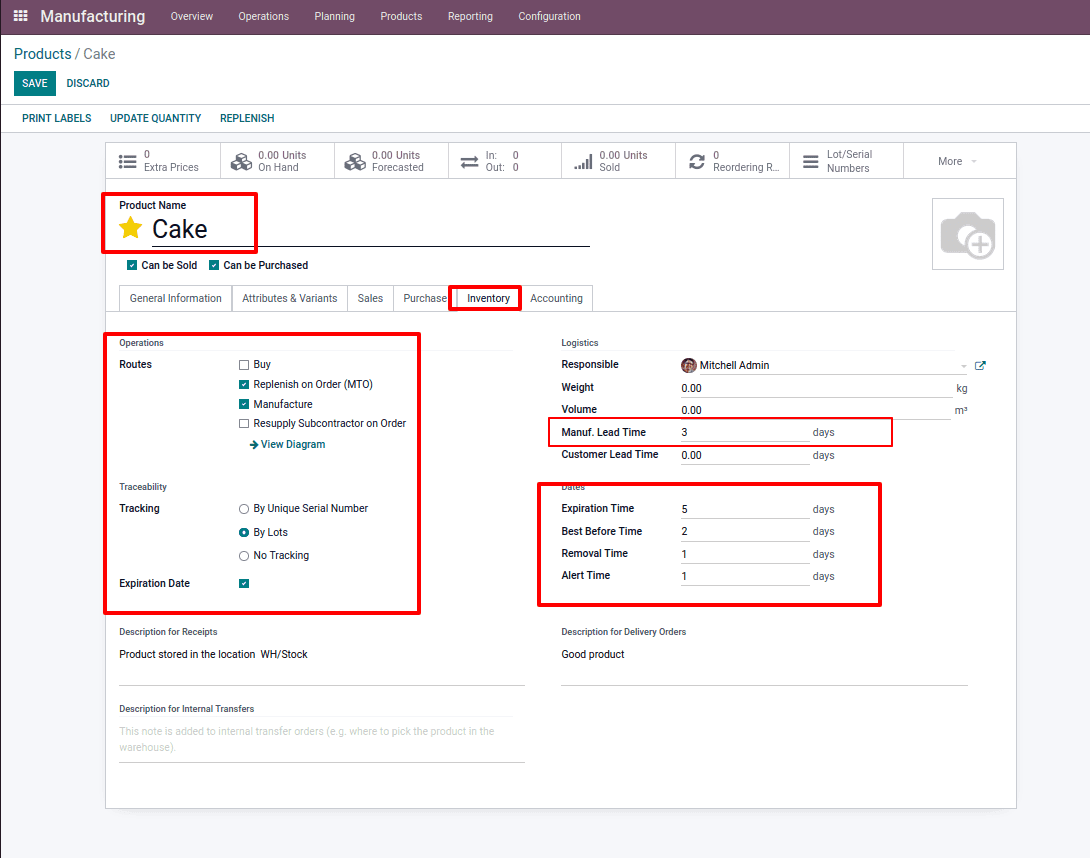

The cake is a product that we manufacture here. For cake manufacturing, first, we have to manufacture cake batter, if not available. As a result, we must enable the route Manufacture for product ‘Cake’ and enable routes Manufacture and Replenish on Order (MTO) for product ‘Batter’ from the Inventory tab for product form.

From the product form, you can also add an Expiration Time and Manufacturing Lead Time to the product.

Here the expiration date is 5 days, so once the product is manufactured, it will expire after 5 days. Manufacturing lead time is the time taken to manufacture the product once an order has been placed.

Work Center configuration

A manufacturing order consists of numerous steps. It begins with gathering raw materials and concludes with the stocking of finished goods. The first step, though, is to set up work centres for each work operation.

To create a work center, we must first set it up.

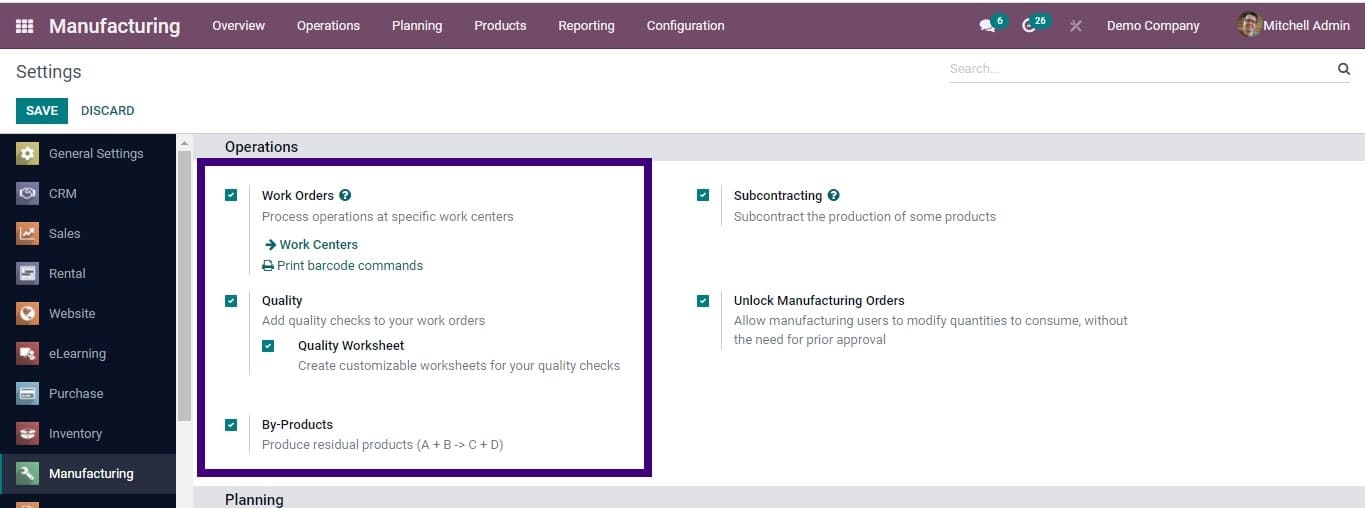

Go to Configuration > Settings > Work center

Enable work center and save.

The work center can be found under the configuration tab. To create a new work center, pick it. A list of previously created work centers is available.

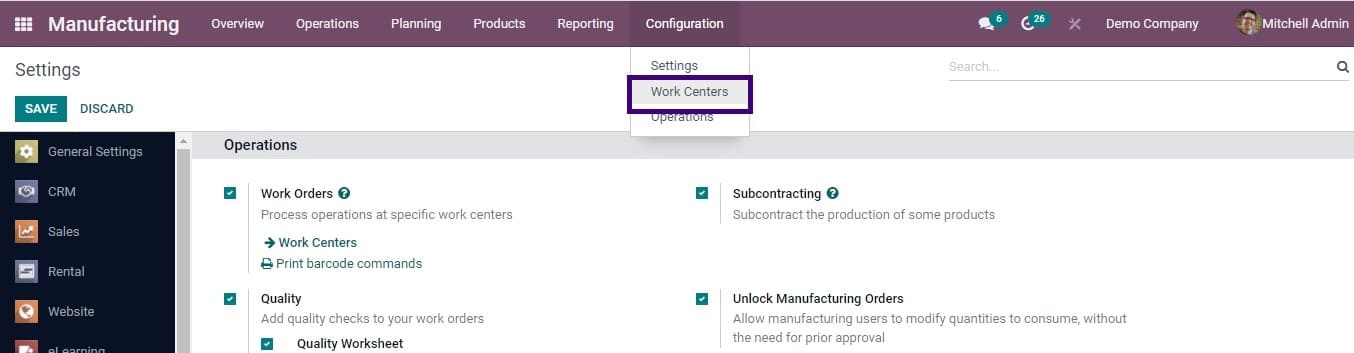

Now go to Configuration > Work center

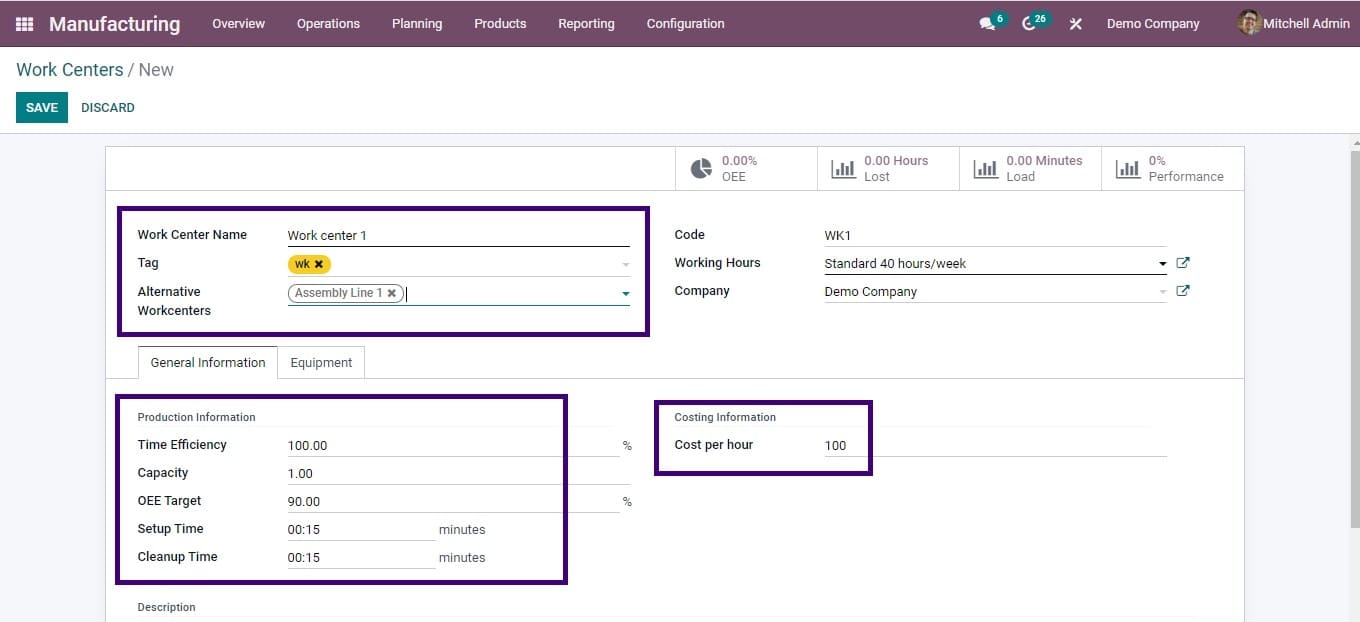

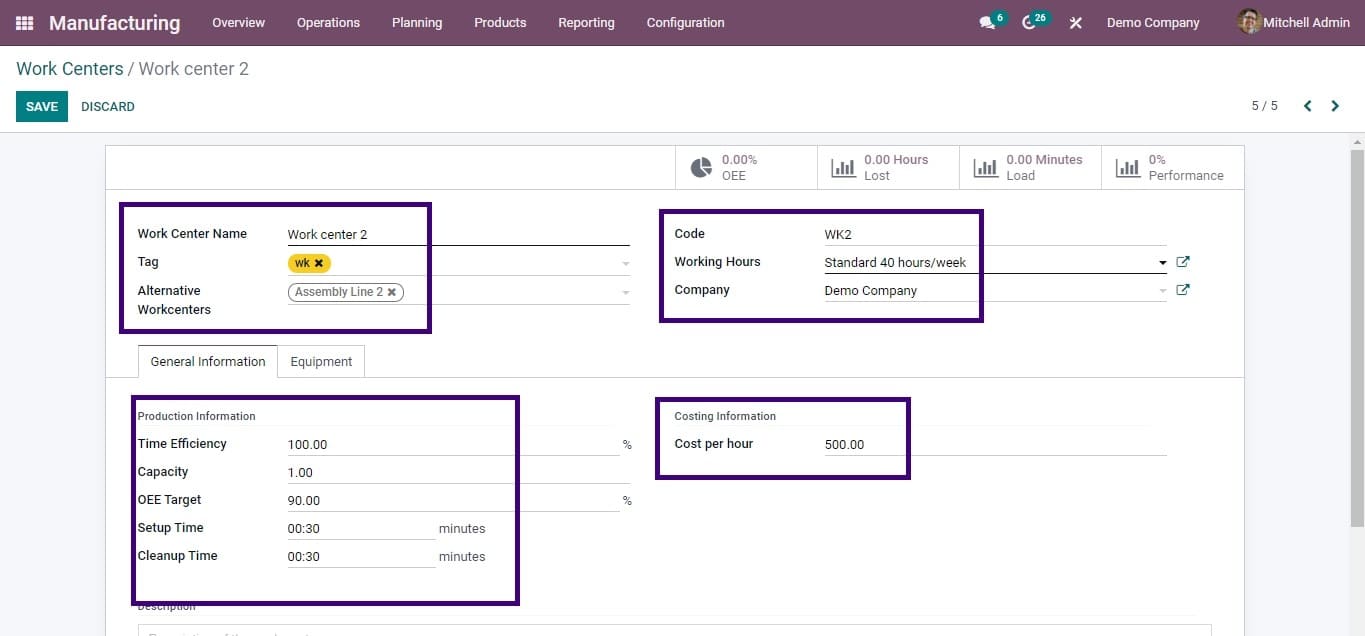

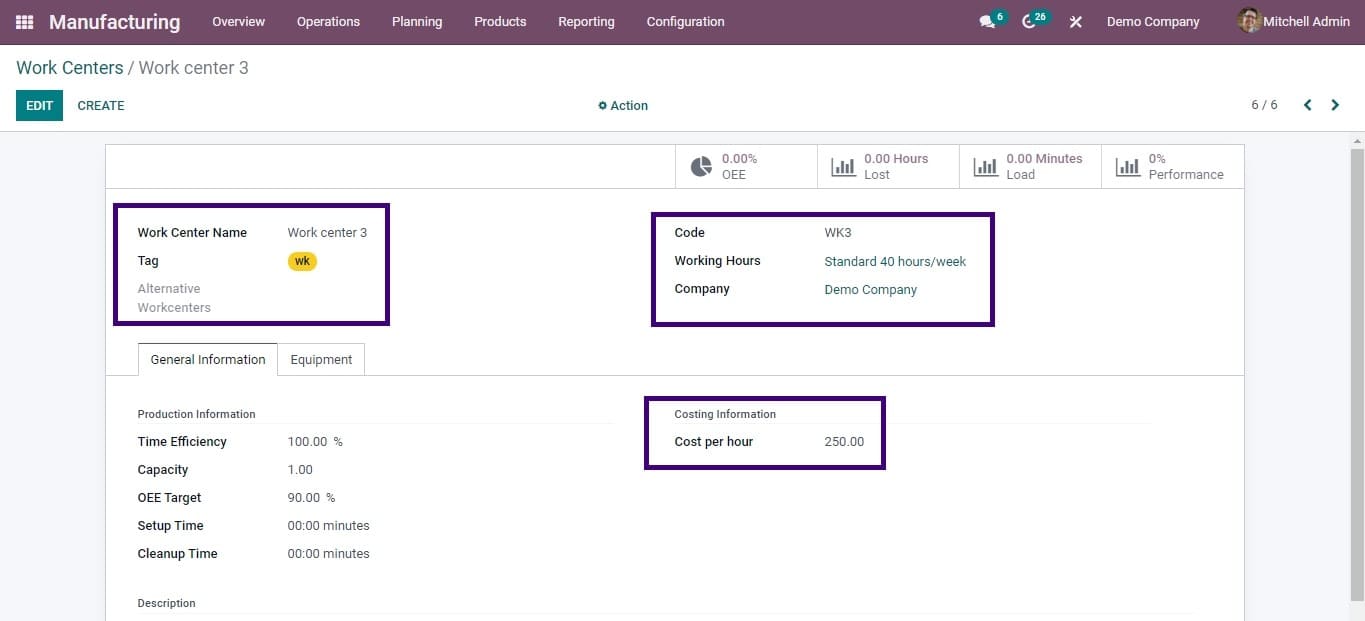

Depending on our operations, we can set up various work centers. Additionally, alternate work centers can be added. Alternative work centers are used as a stand-in for our main work center. When our main work center is busy, the operation is moved to the alternative work center. The time efficiency field is used to compute the predicted work duration, while the capacity field is used to add the number of items that can be manufactured in parallel. We can also add the time it takes to set up and clean the equipment. Additionally include the hourly cost of the work center. The list of equipment used in the work center can be added to the equipment tab. This tab is only available after the Maintenance module has been installed from the App.

Create three different work centers for three procedures such as mixing, baking, and packing, for example, while creating a manufacturing order for a cake.

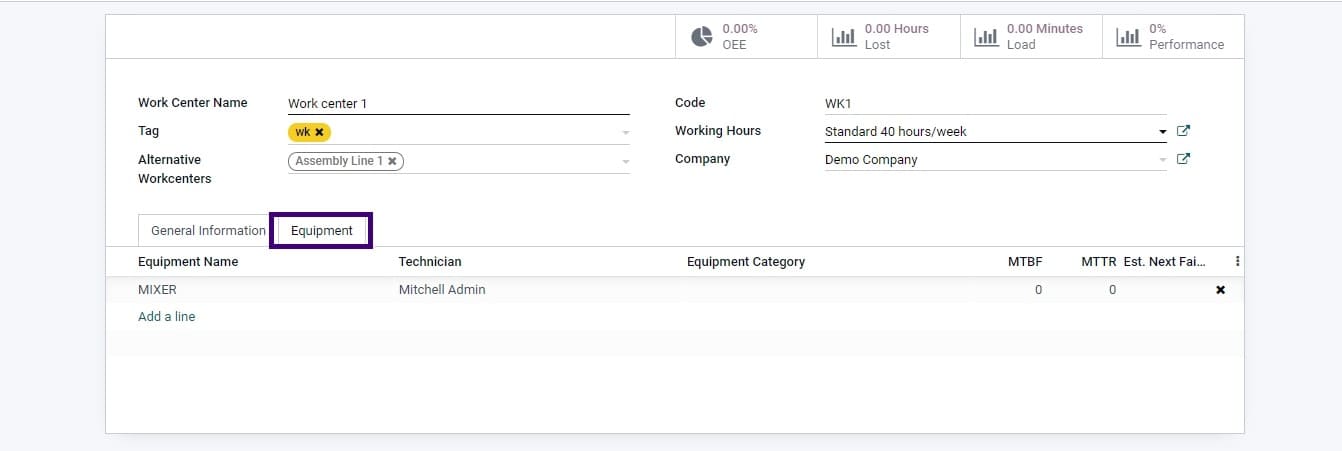

Workcenter 1 was constructed for the mixing process, and Assembly Line 1 was added as an alternate work center. It takes 15 minutes to set up as well as clean. The hourly rate is 100. Add process equipment to the equipment tab. Add code WK1.

Create a second work center for the baking process, with each work center taking 30 minutes to set up and clean.

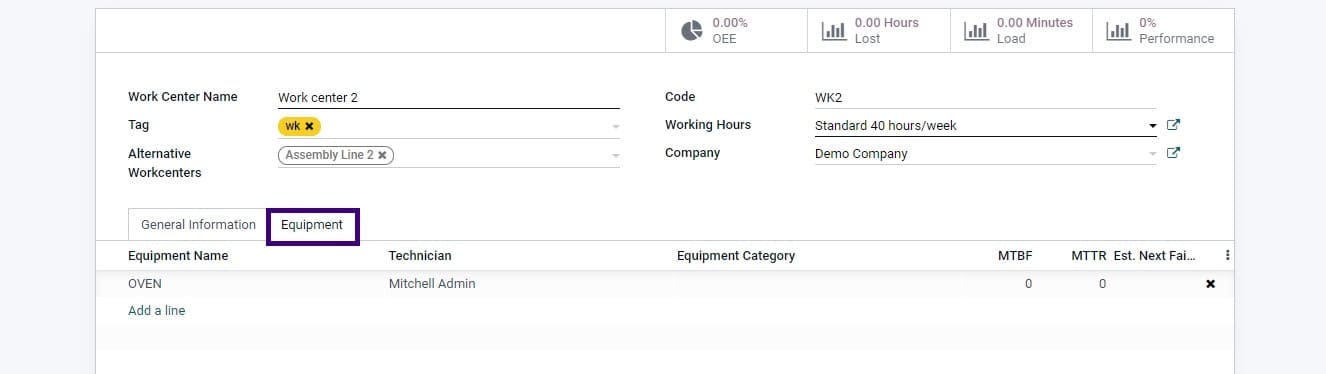

The work center’s code is WK2, the hourly cost is 500, and the oven is the used equipment.

The third work center is used for the packing process. WK3 is the code, and the hourly rate is 250.

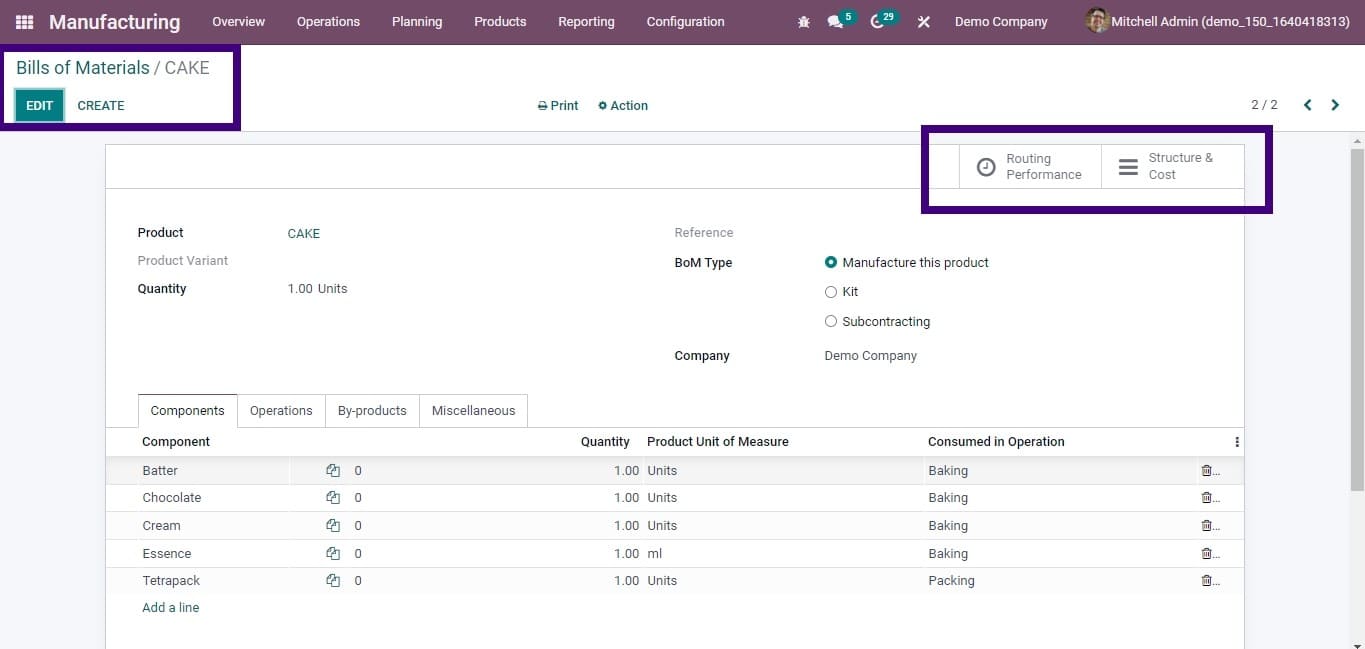

Bill of Material

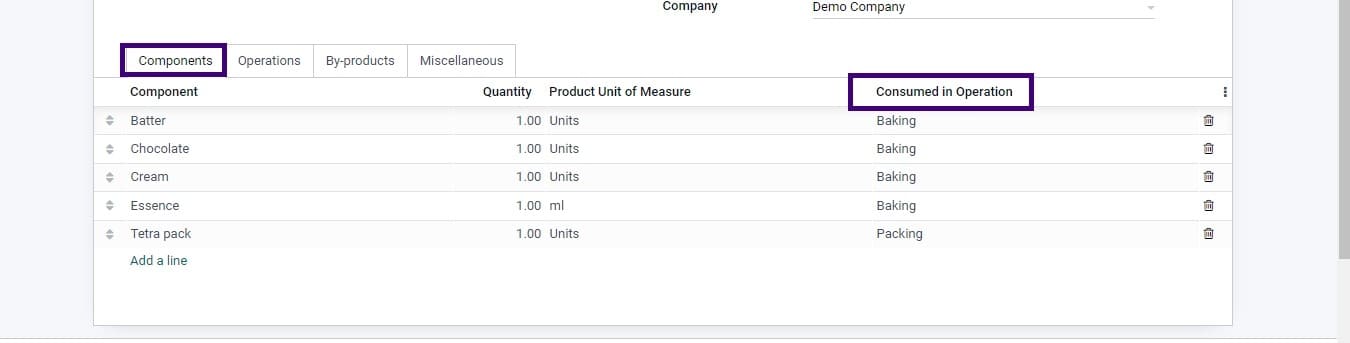

The second step in manufacturing is to create a bill of materials. A bill lists the components that were used and the operations that were performed. If any byproducts are formed during the production process, we can specify them in the bill of materials.

From the product tab, we may choose a bill of material.

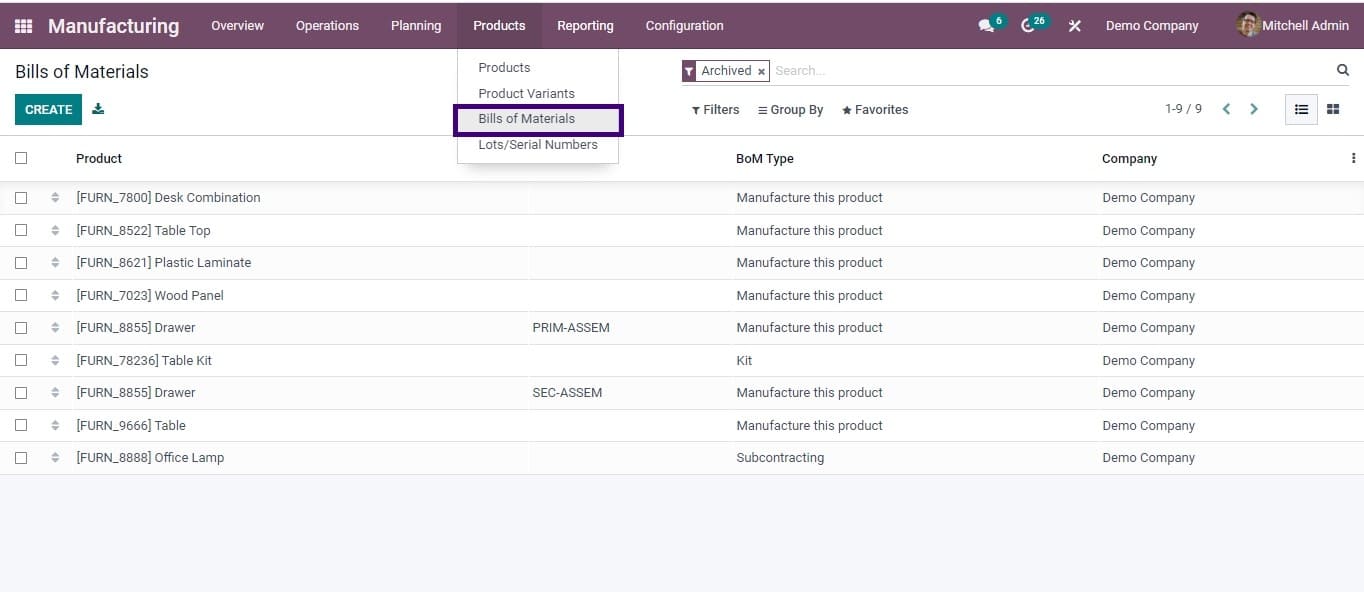

Go to Products > Bill of Materials.

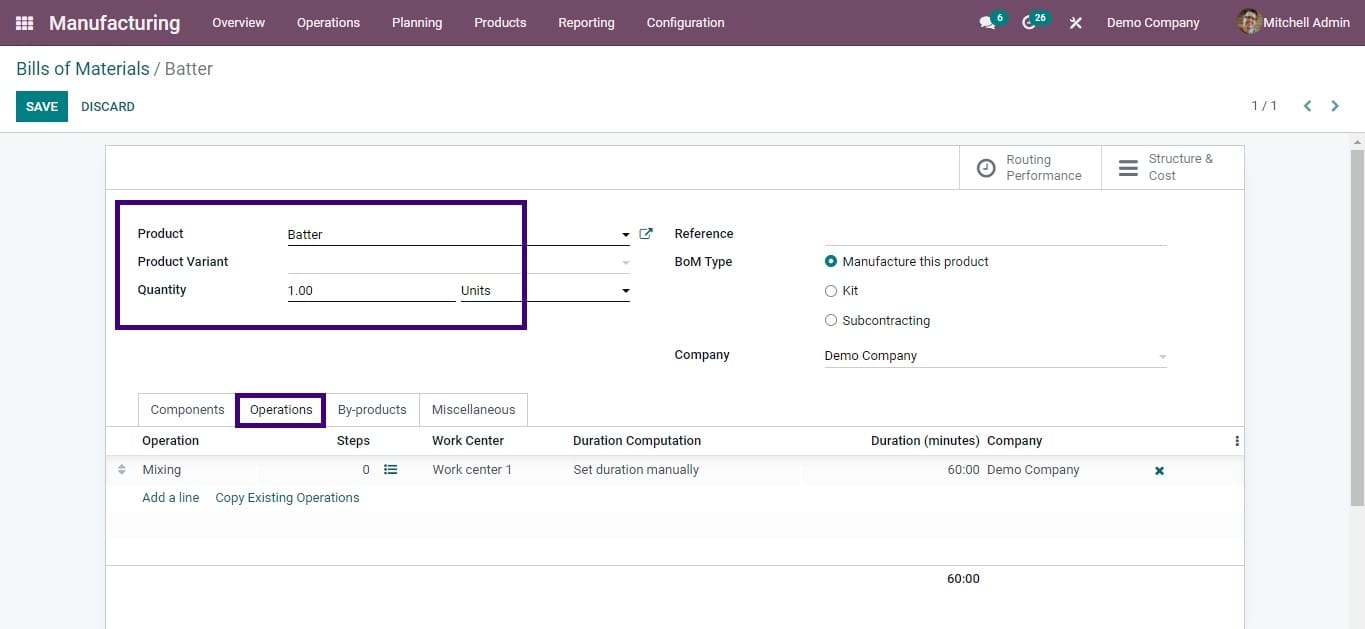

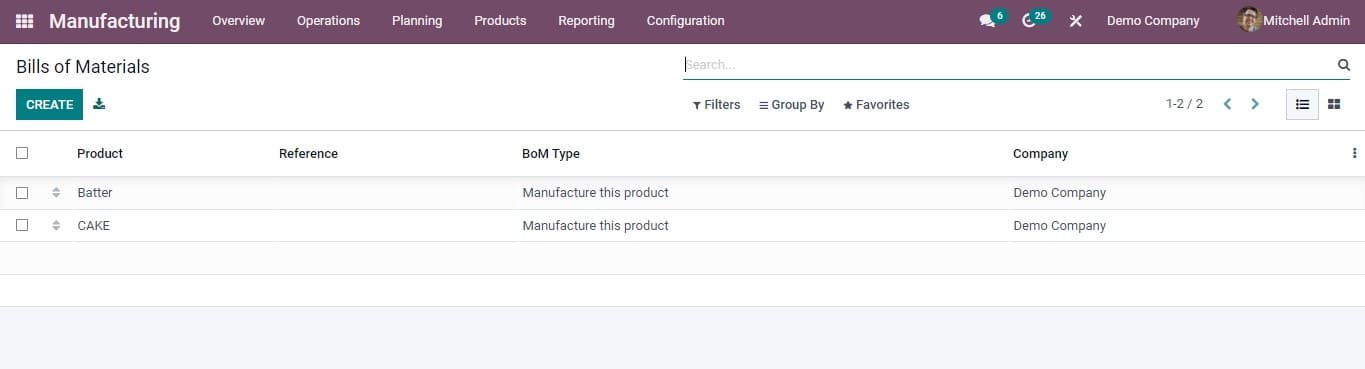

For production, we can add multiple bills of material. For example, when making a cake, batter is required, which is to manufacture separately. Creating a bill of materials for a batter comes first.

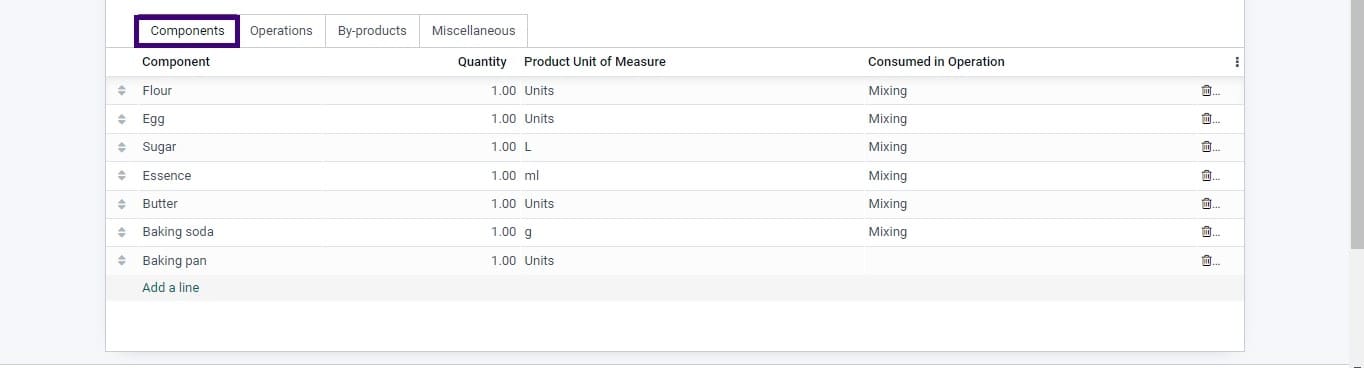

The components for making batter were added, and the process was mixing. For each component, we can specify the consumed operation separately.

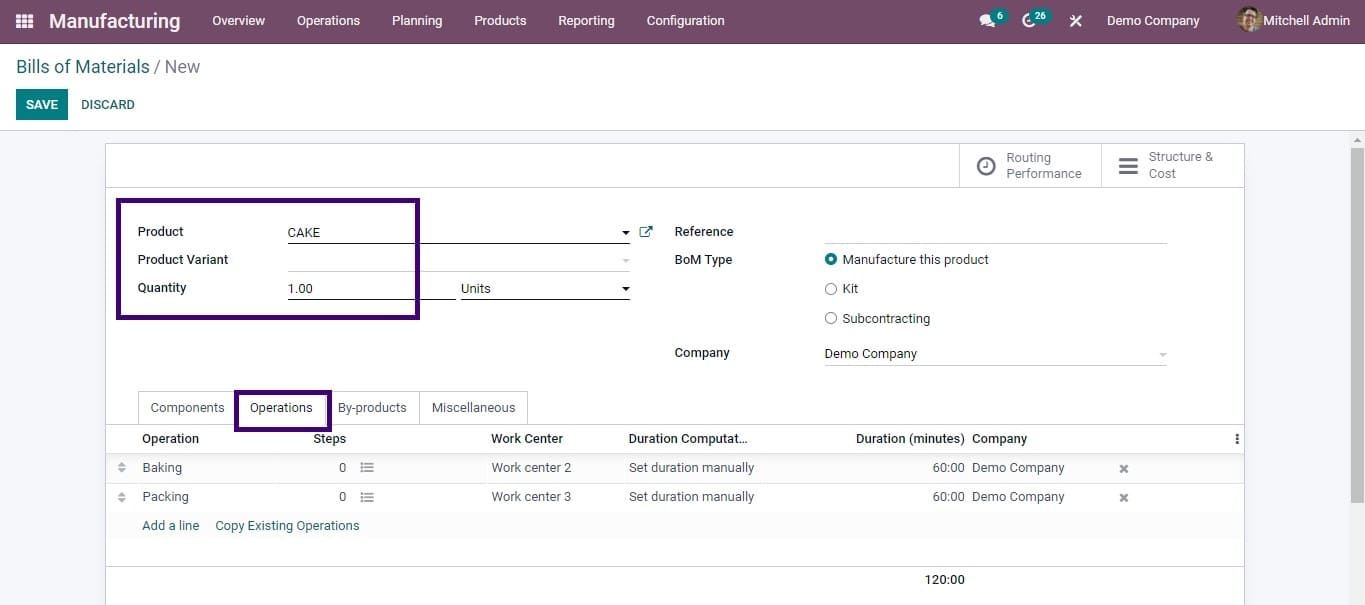

After that, we’ll be able to generate our main bill of materials for the product cake.

Add the right components, including batter, and define the operations to be performed (Baking and Packing). Separately define the operation performed in each component.

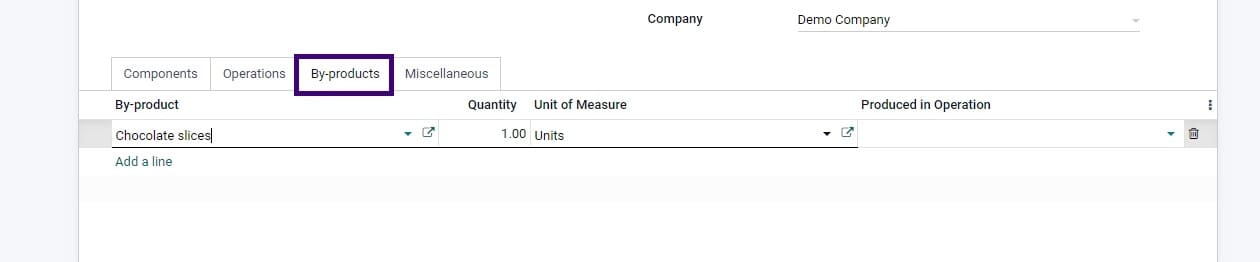

In the By-Products tab, add the by-products that will be generated during this manufacturing process.

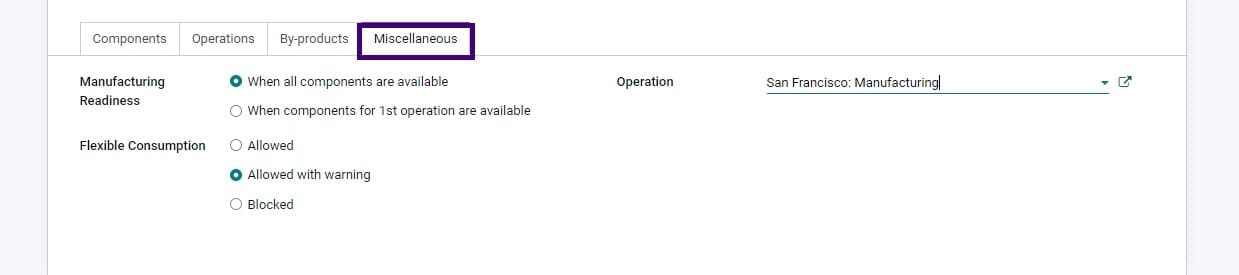

In the miscellaneous tab, Flexible consumption specifies what to do when we consume more components than defined and manufacturing readiness specifies how to work depending on component availability.

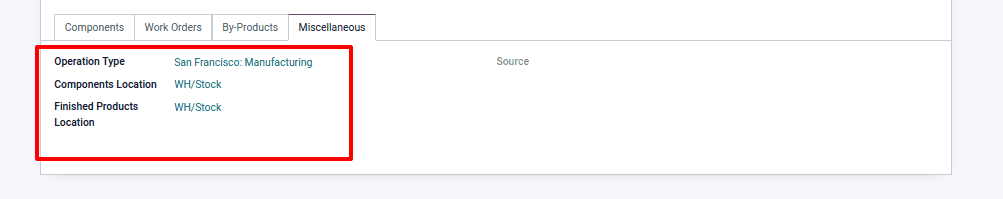

We selected ‘San Francisco: Manufacturing’ as the operation type in the Miscellaneous tab. The source and destination locations are also mentioned in the operation type. so, the components are taken from the source location for production and the final product is transported to the destination location after the production.

Now the Bill of Material for Batter and Cake is ready.

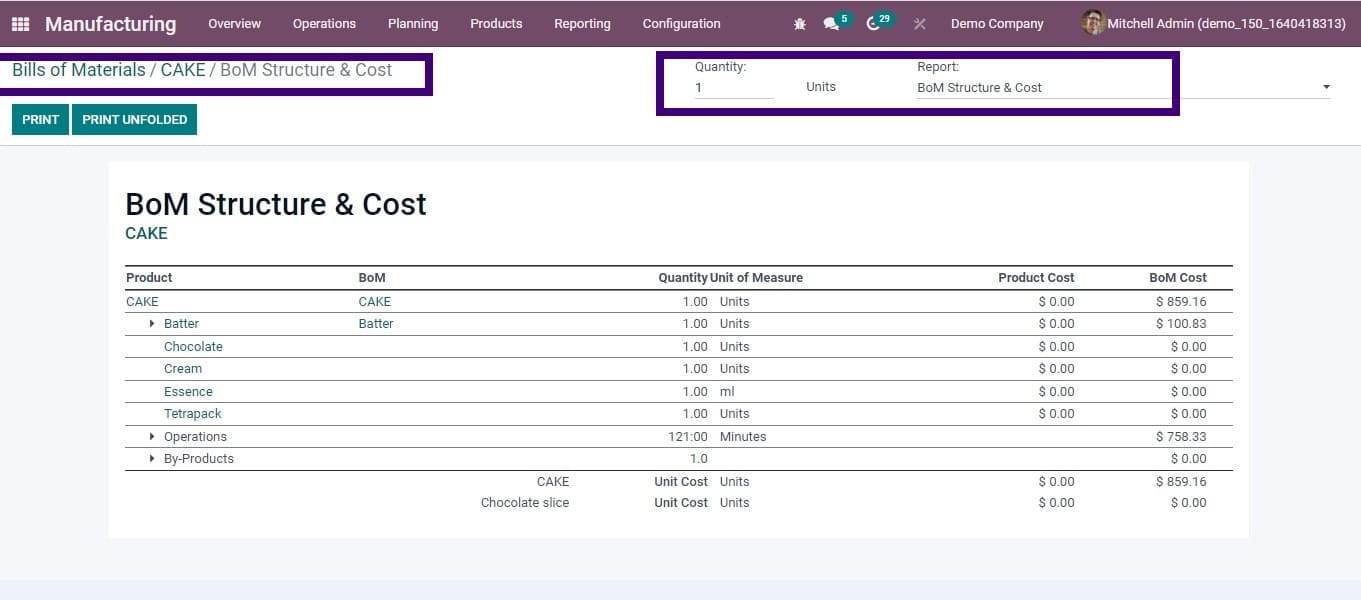

We can take an estimate of cost production for multiple products from the smart tab Structure and Cost.

As the quantity, the total cost updates according to it.

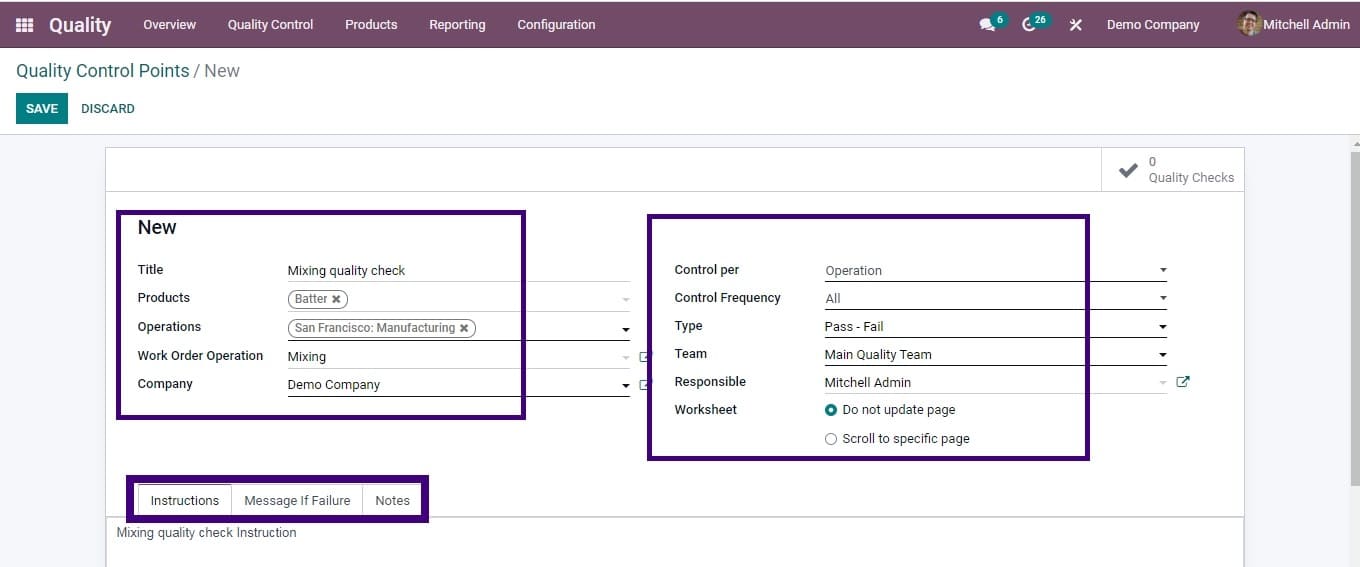

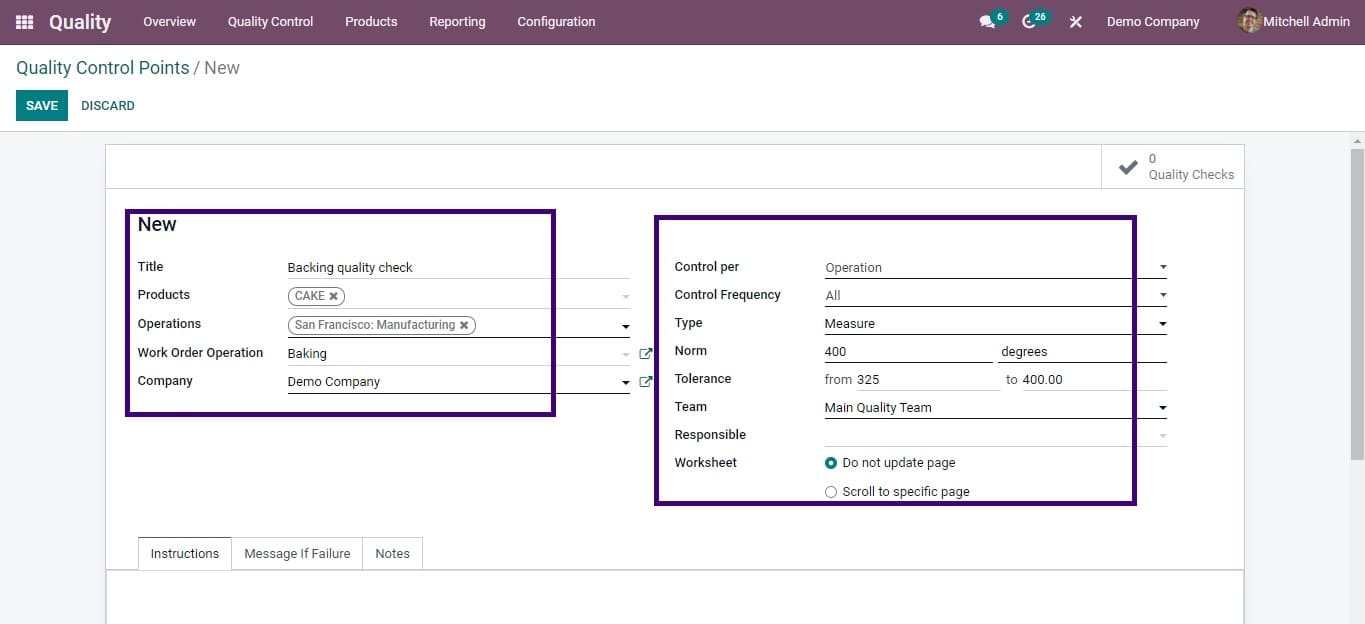

Quality

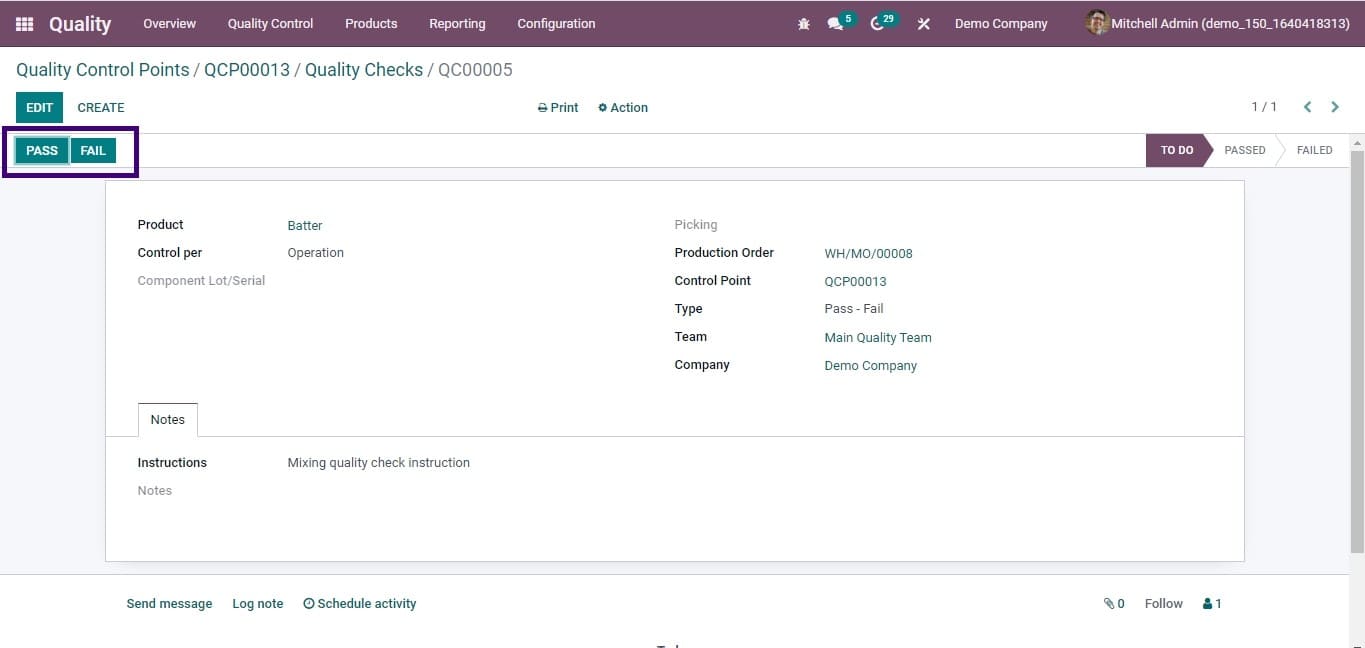

The quality module can be used to check the quality of the product created during each operation. For each operation, we can add Quality Control Points. We can add the correct type of Quality checks for each operation to ensure the quality of the final product.

We can construct a quality check for the mixing operation and baking operation. Include the operation and specify it in the Work order operation tab. We can also add instructions, failed messages, and notes in the smart tabs. as well as a good team and a responsible person

Manufacturing order

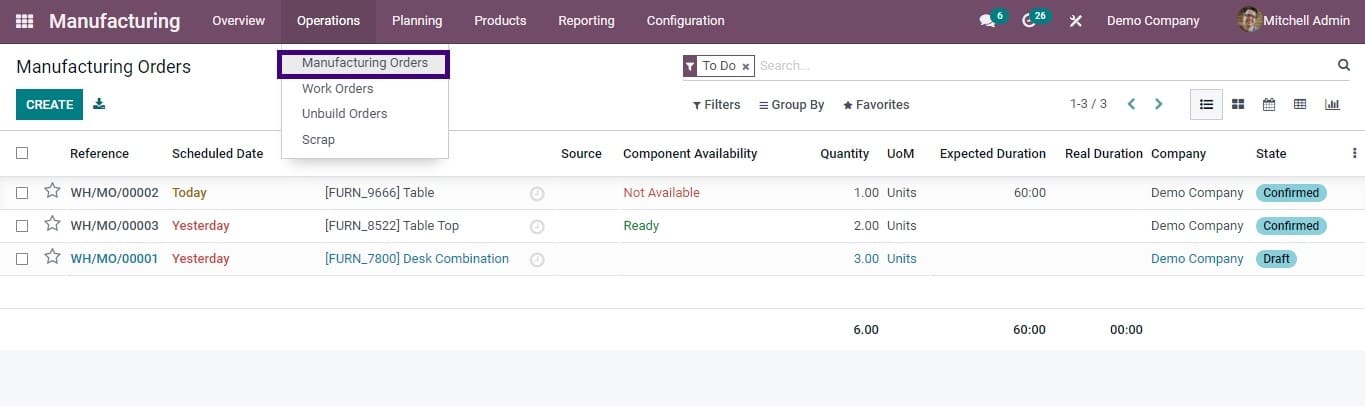

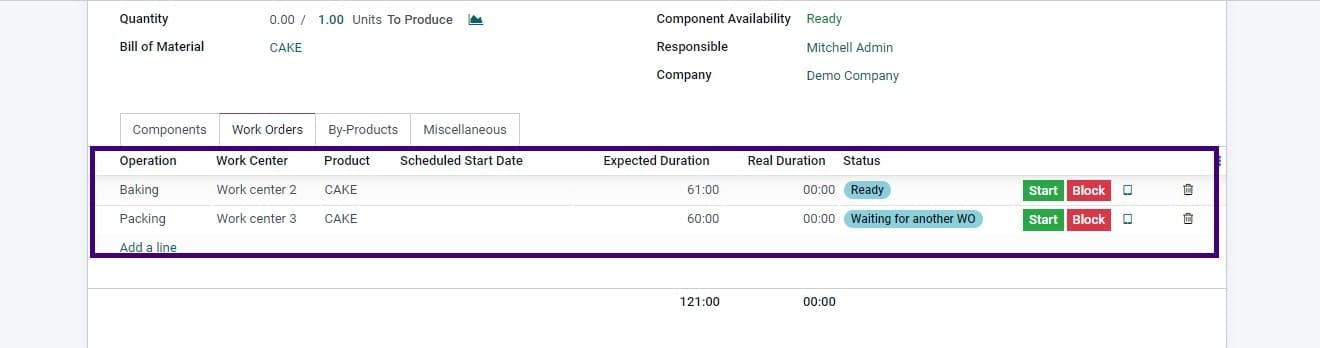

Go to the Operations tab and make a manufacturing order for the product cake to make a manufacturing order.

When we add a product name and a bill of materials, a list of components and operations to a manufacturing order is automatically inserted.

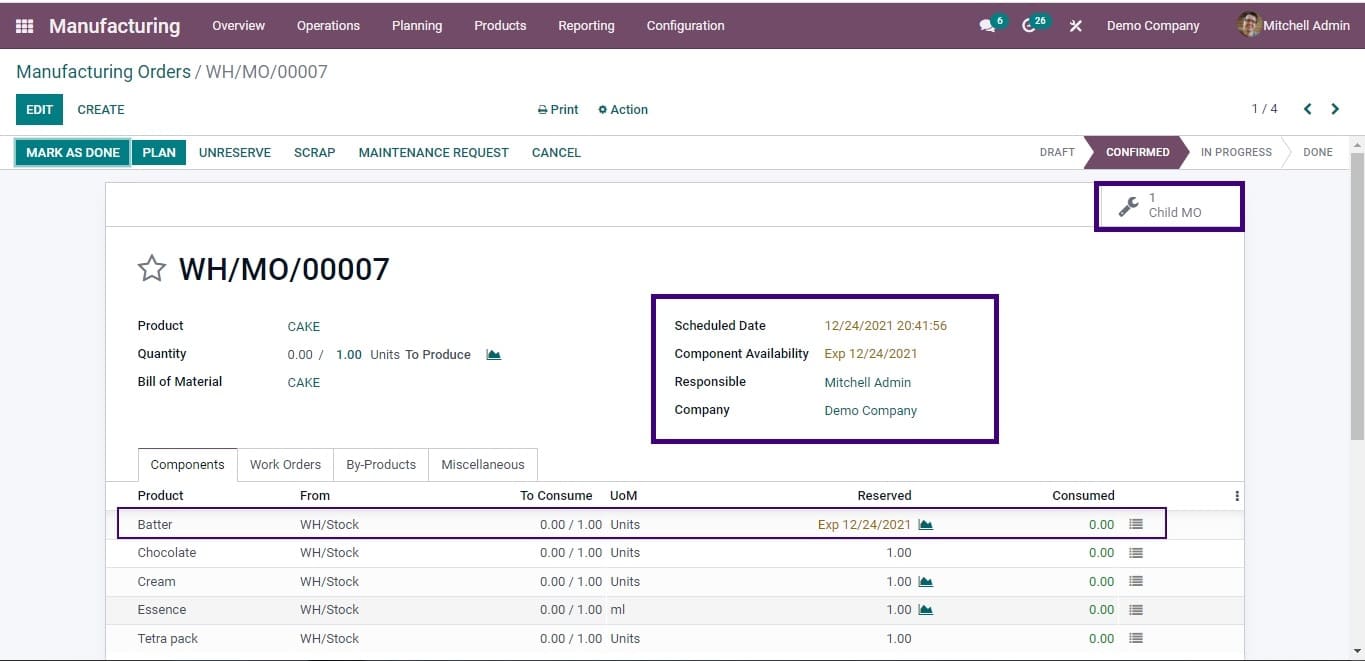

The final product and by-product can both be added to a specific area. Mention the location in the production order’s miscellaneous tab. Otherwise, the product goes to the place provided in the operation type.

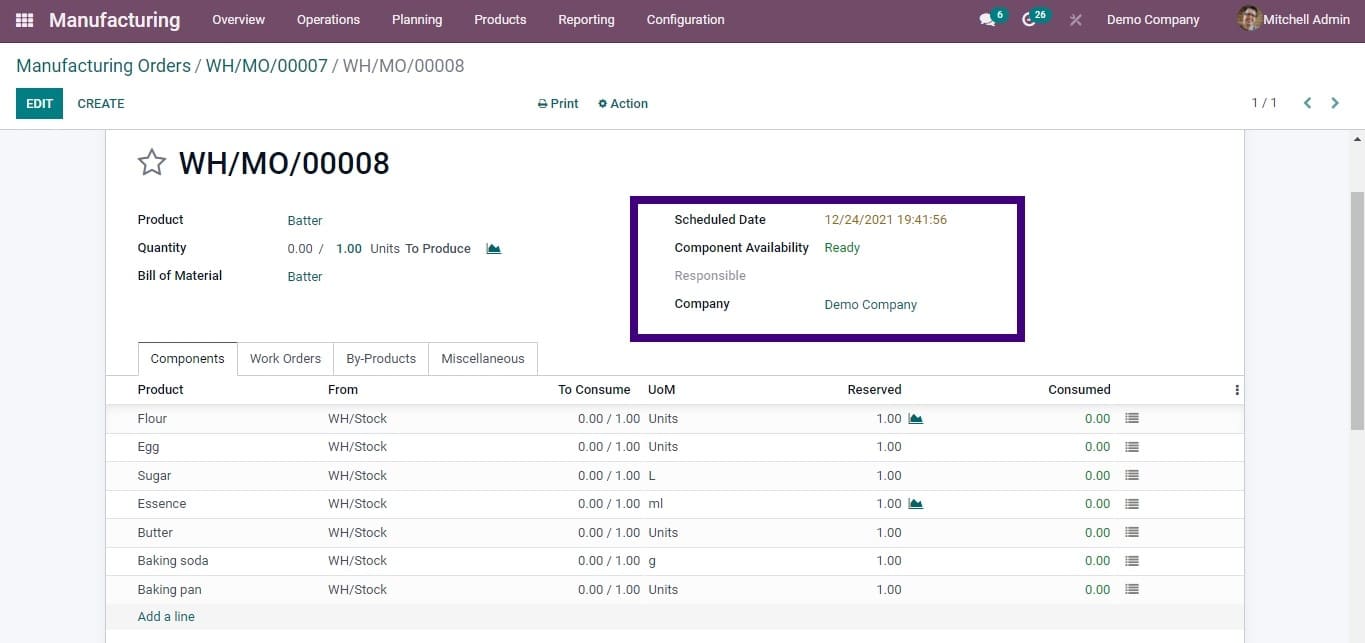

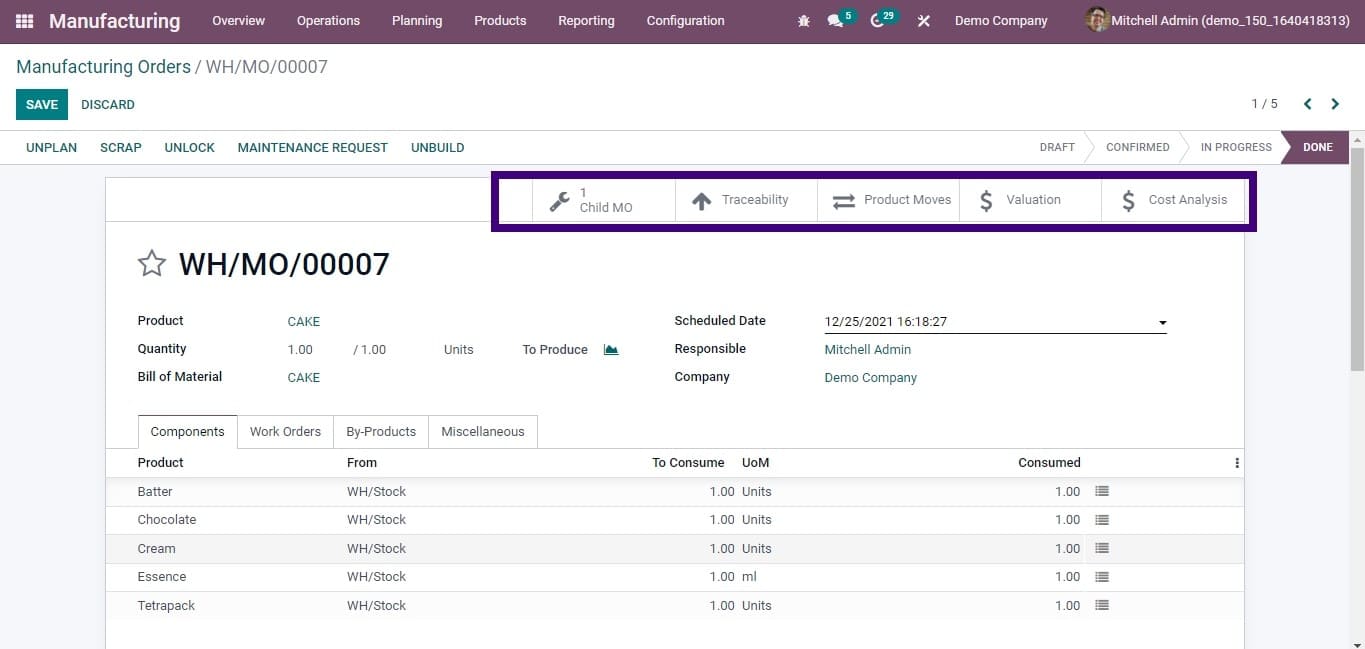

However, if the component Batter is unavailable, a child MO is formed when we confirm the order. While selecting Child MO from the smart tab, we can see a manufacturing order for the batter is created.

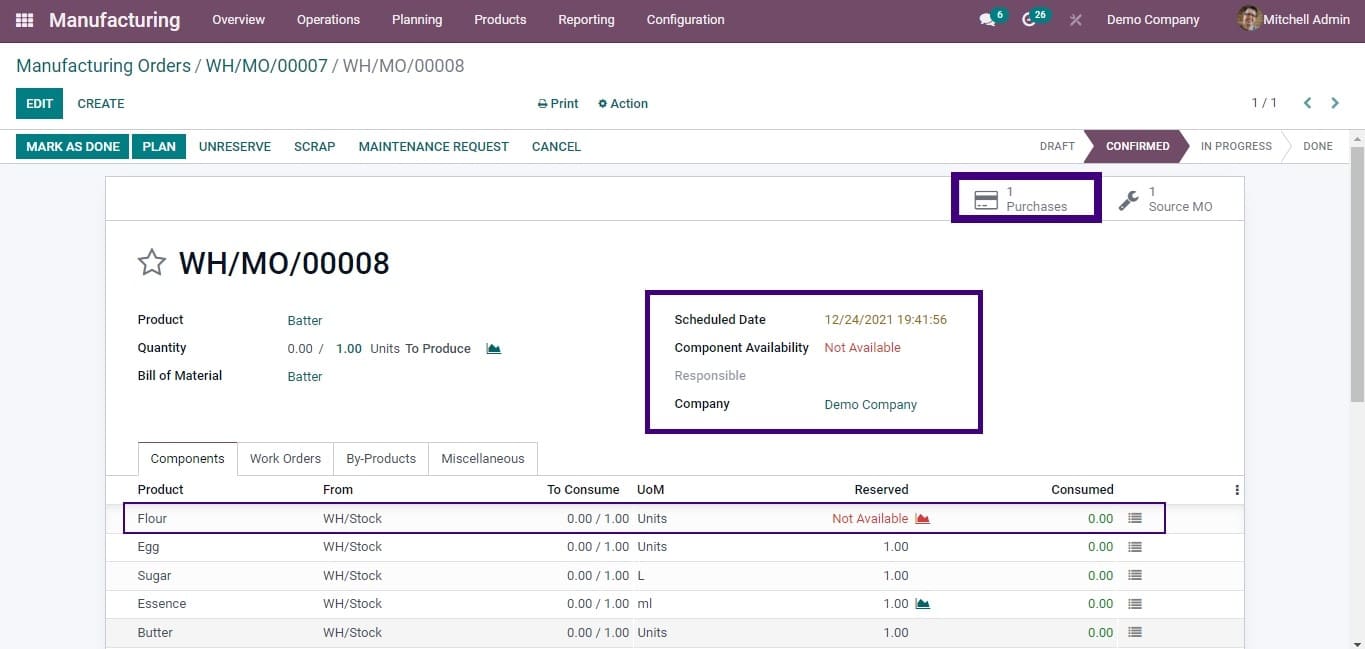

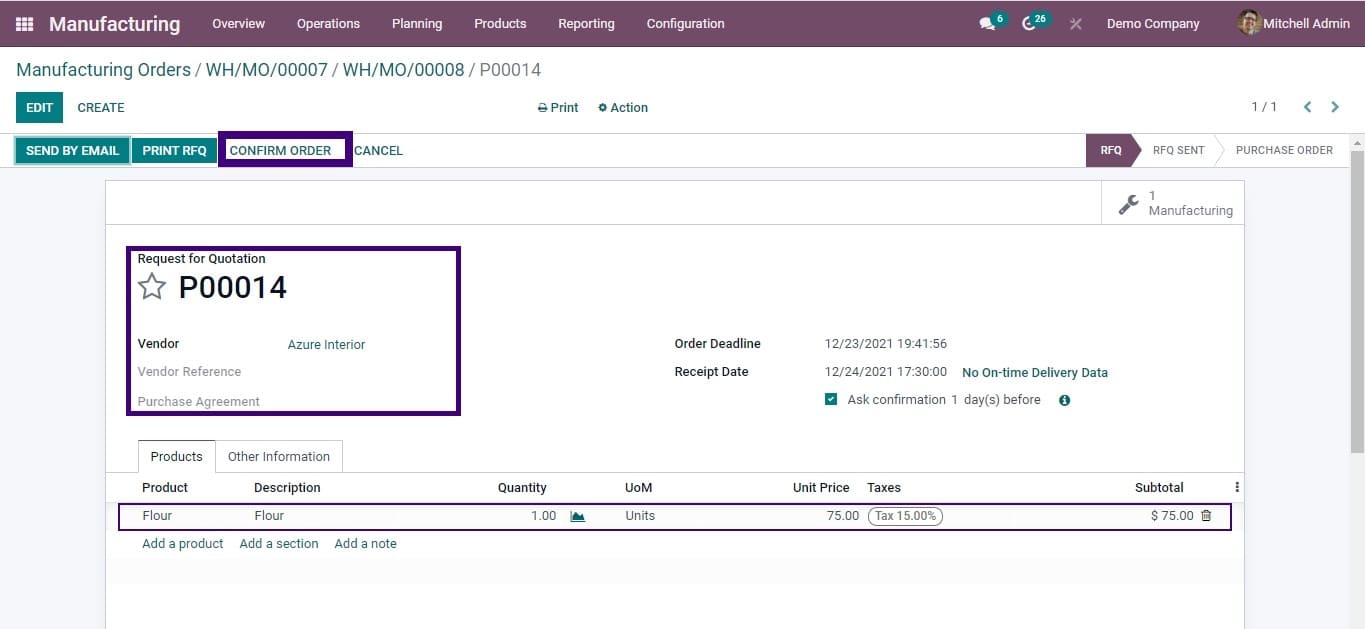

We can see there is a purchase order created in the smart tab.

Because it is possible to buy a component right before the manufacturing order is processed. The product must be storable, the vendor must be defined in the purchase tab, and the route must be Buy and Replenish on Order(MTO).

We may confirm the manufacturing order for Batter once we have the products from the purchase order.

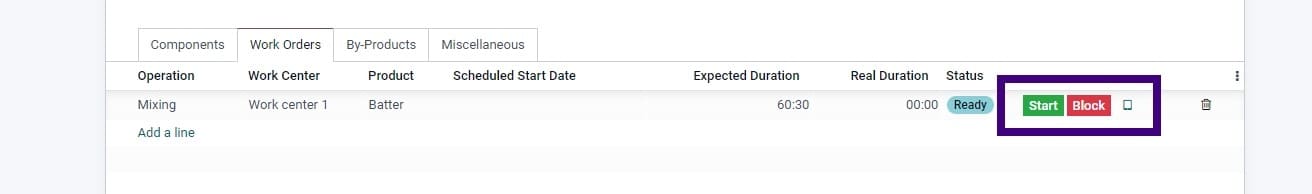

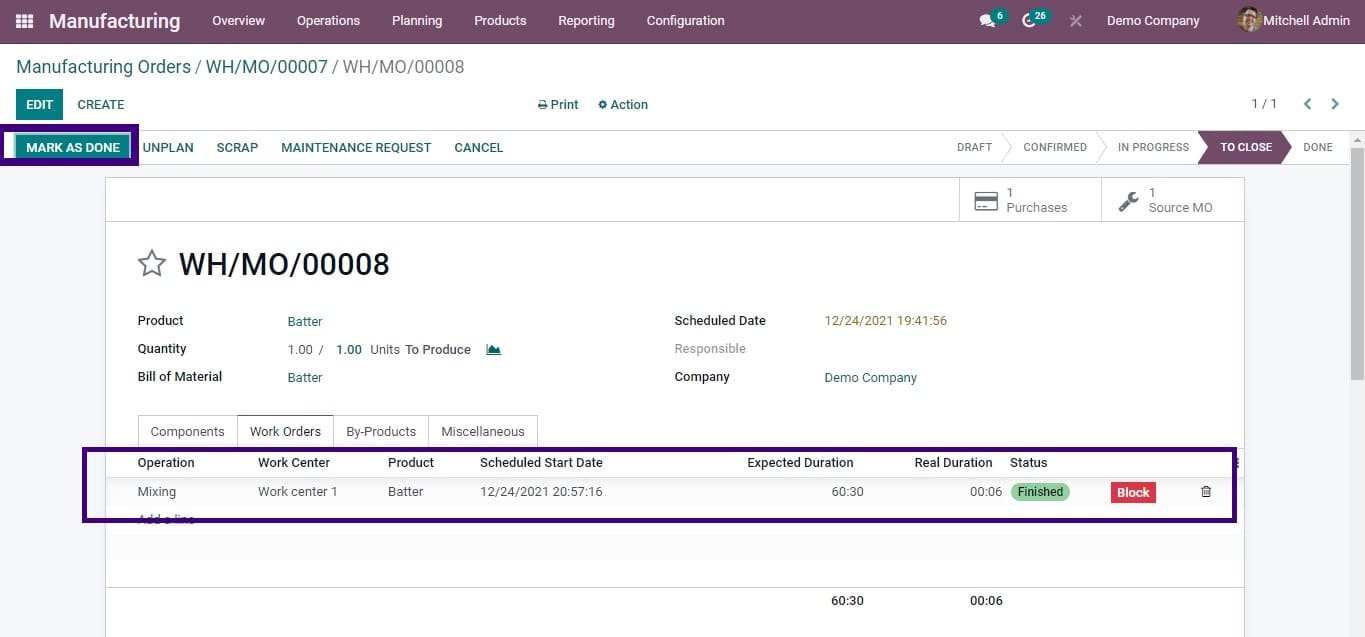

The Child MO now has access to all components. We can start mixing from the operation tab.

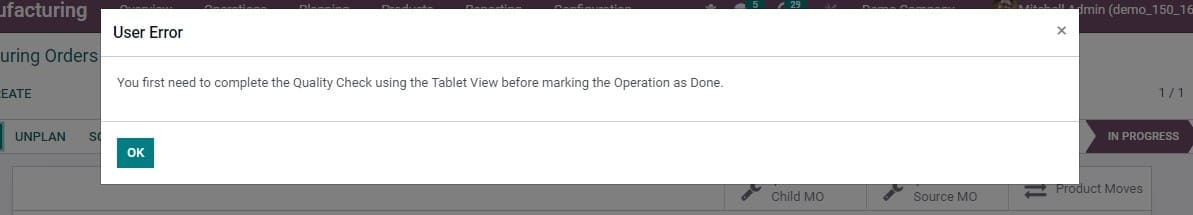

Before finishing a pop-up message alerting us to the quality check, we can only proceed with the operation after the quality check has passed.

After finishing the quality check, Complete the Child MO by clicking the Mark as Done.

Then we can move on with the source manufacturing order.

Each operation is completed only when all quality checks have been completed.

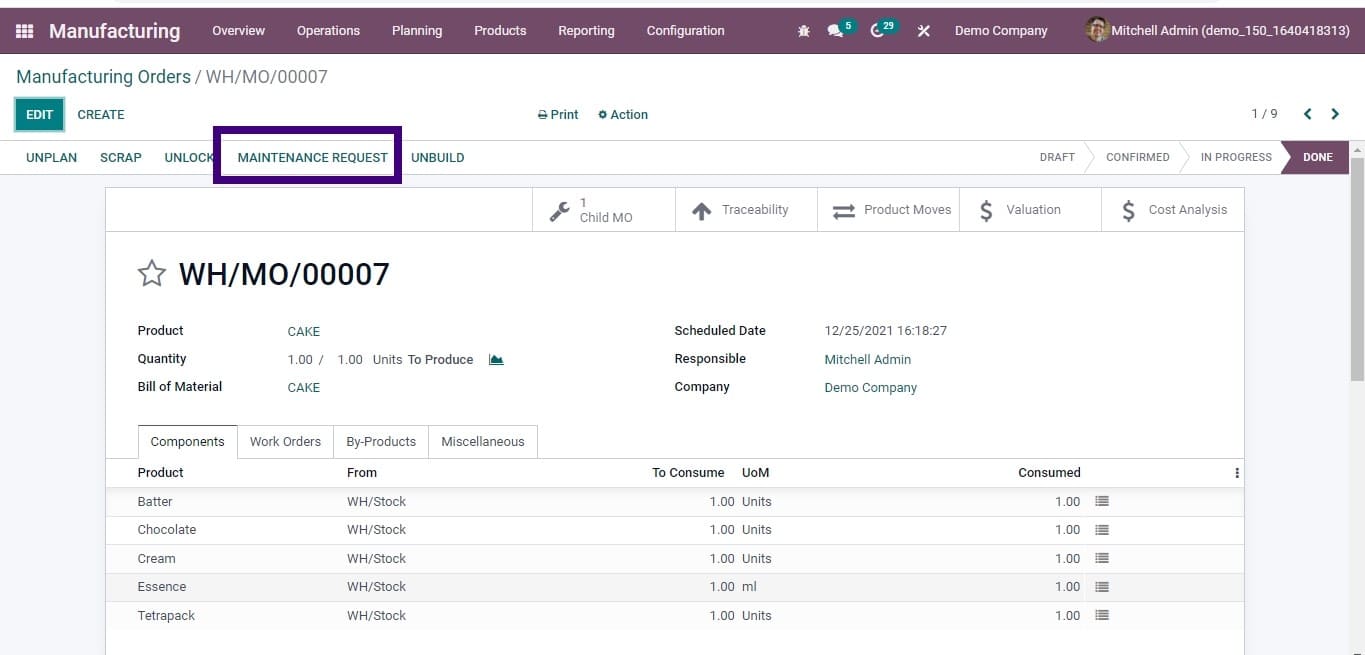

Then click the Mark as Done to complete the order. The final product and by-products are transported to the destination location.

Maintenance

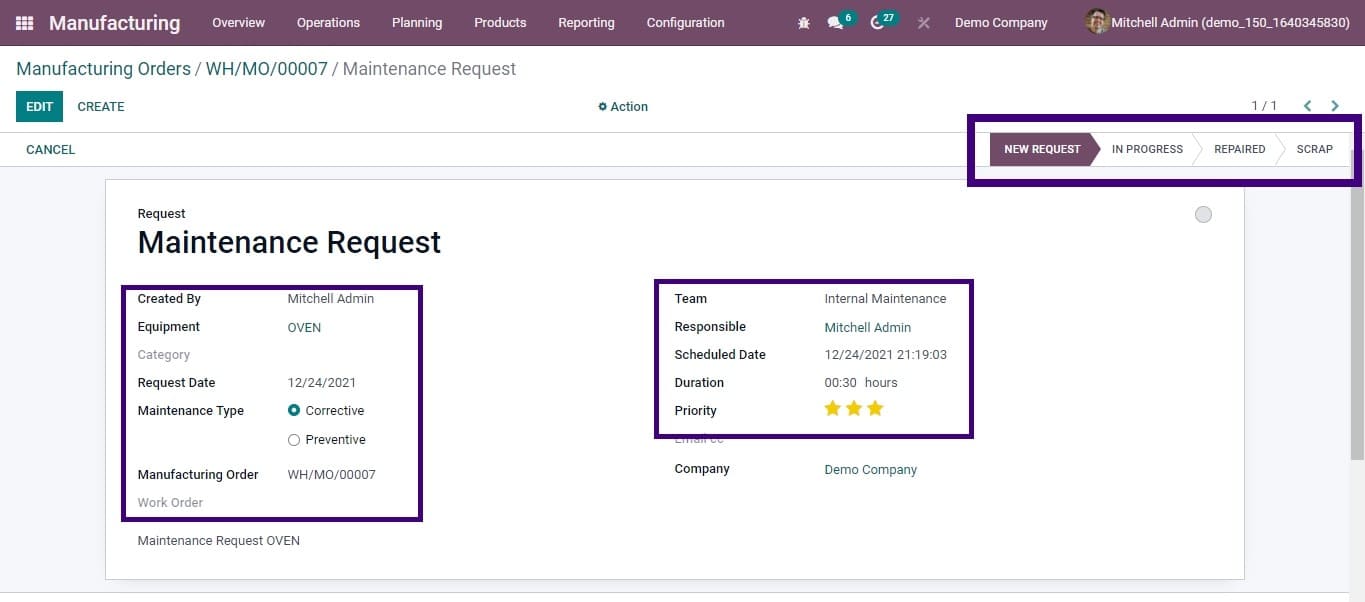

We worked with lots of machinery in the manufacturing process. As a result, it is critical to maintaining these machines. From a manufacturing order, we can generate a Maintenance Request. The Maintenance module from Apps is required for this.

Add information such as equipment, maintenance team, type, and date.

After that, save the request and proceed to the next stage.

We acquire information such as Traceability, Product moves, Valuation, and Cost analysis after finishing a manufacturing order from the smart tab of manufacturing requests.

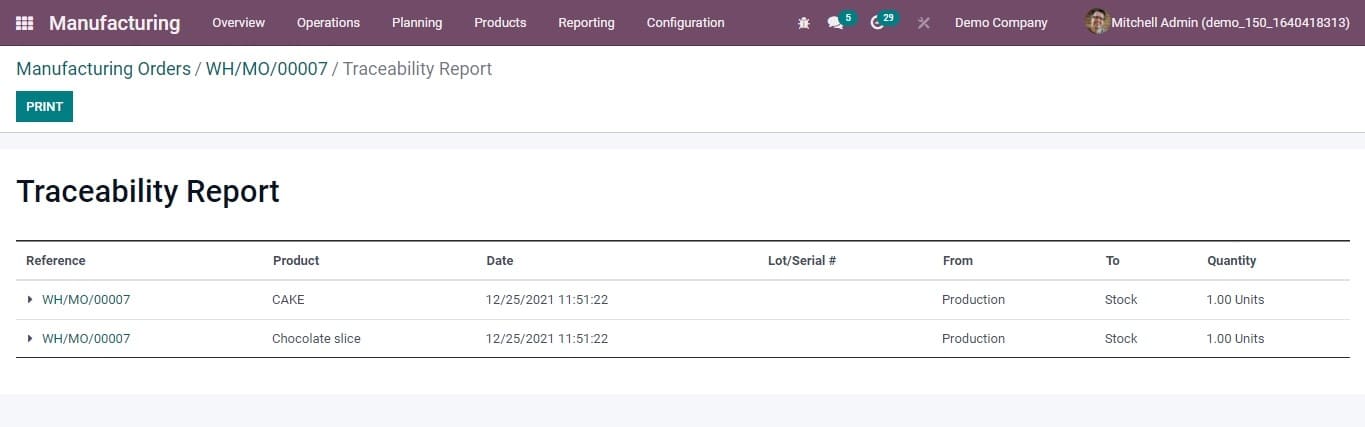

Traceability Report

We acquire information about the final product and by-products developed from the Traceability Report.

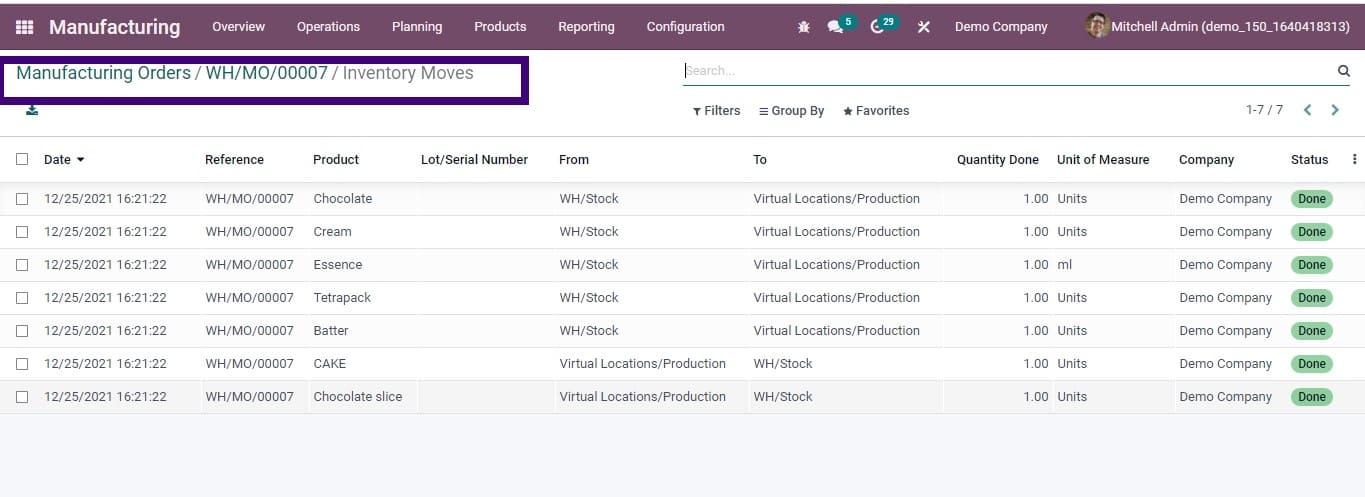

Product moves

We may learn about the inventory movements of components used and goods manufactured in the production order by looking at product moves.

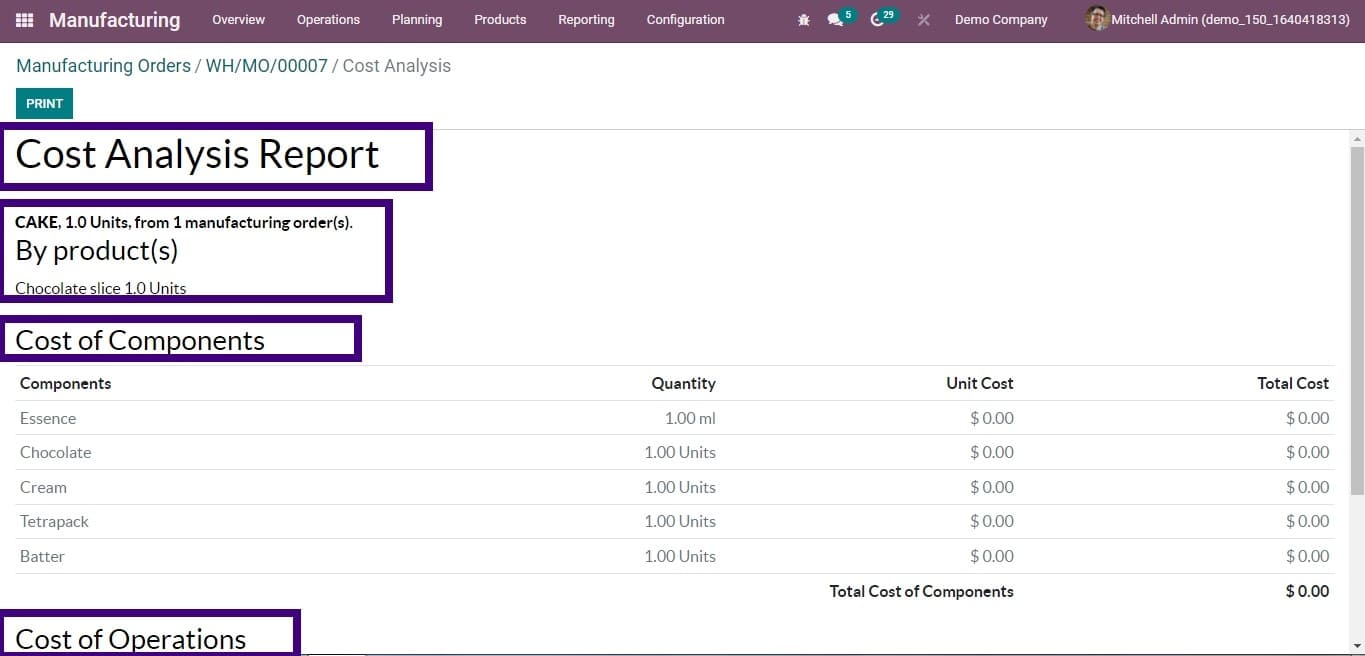

Cost Analysis

We acquire the cost of components and the cost of operation separately from the cost analysis report.

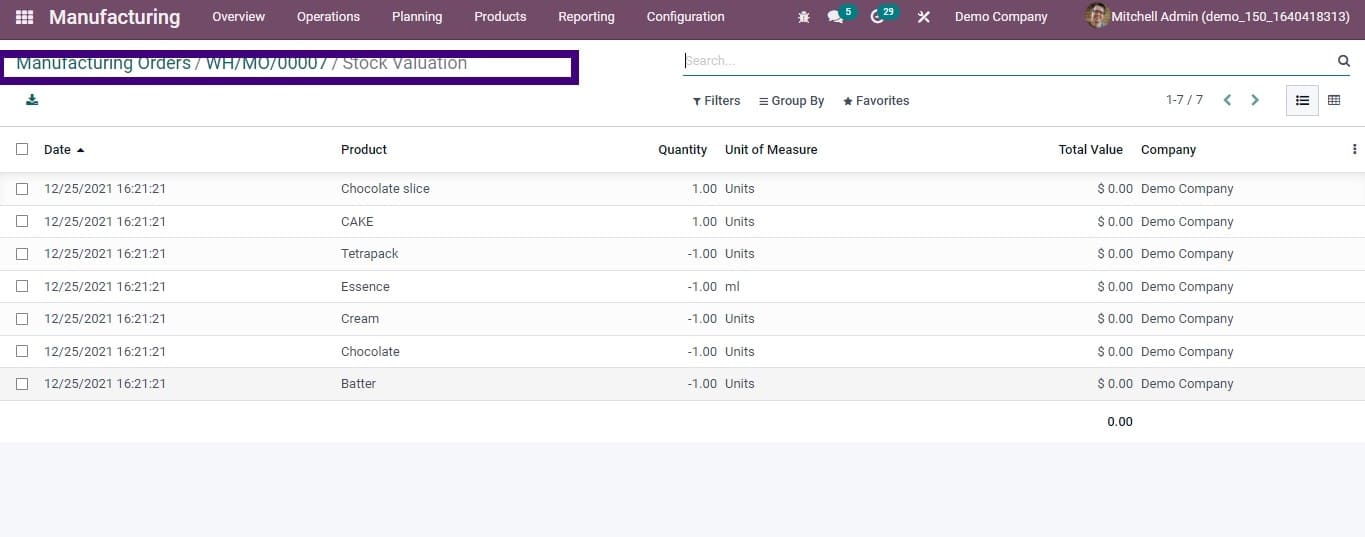

Valuation

We get stock information here from the stock valuation. The number of utilized components is negative, but the quantity of manufactured products is positive.

Food Manufacturing is a large process with multiple Bills of Materials and numerous functions, which is easily manageable, and tracking operations are made flexible with odoo.

To read more about the importance of Odoo Manufacturing Software, refer to our industry page Odoo Manufacturing Software