In the manufacturing industry, there may be different and distinct phases in the product manufacturing process. Each process will require separate protocols as multiple types of equipment are required to process them. So it is really important to set multiple physical spaces for a specific process. The work center in the manufacturing industry is the place where specific processes take place. In any manufacturing industry, there may have different work centers. These are said to be the physical spaces where different kinds of production procedures take place.

Odoo 14 provides the user with support to set the work order in different work centers in the manufacturing of products. Creating a work center in Odoo 14 requires the same steps as in Odoo 13. However, in Odoo 14, the usage of the work center can be assigned in the manufacturing order itself. The productivity of the work center is predominantly measured by its capacity, efficiency factor, etc.

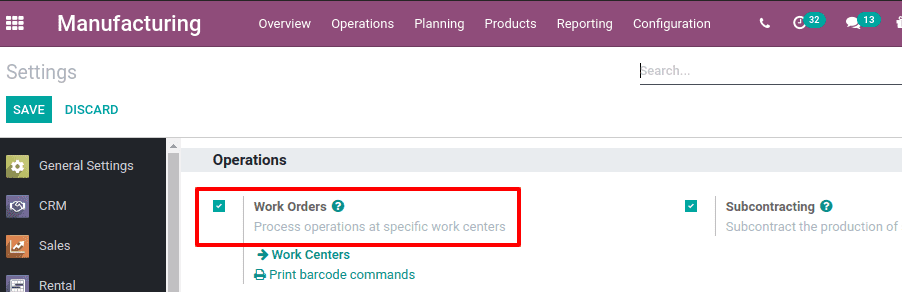

Firstly, enable the work center from the manufacturing configuration settings, Manufacturing Module > Configuration > Setting > Work order.

Save the changes, once the option work orders are activated.

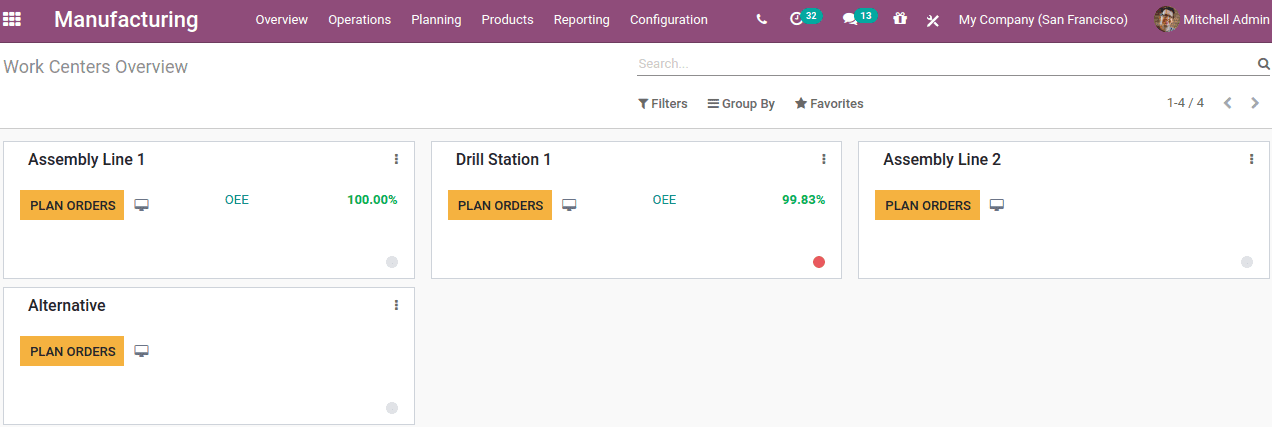

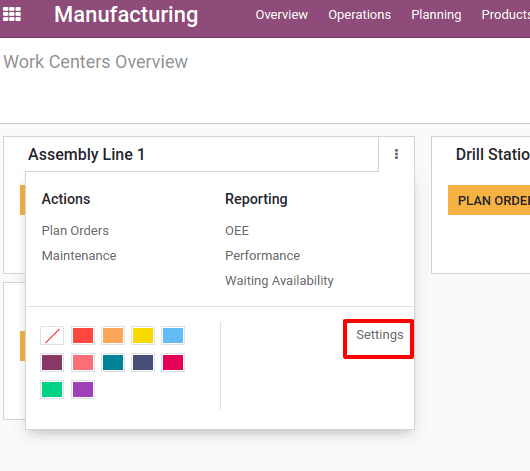

The manufacturing overview shows the existing work center details. One can plan orders or make maintenance requests from the overview by clicking the three dots. This will give you options to plan order, maintenance, and reporting.

The settings option leads you to the details of the work center, where one can set the capacity, efficiency, alternative work center if needed, costing information, etc.

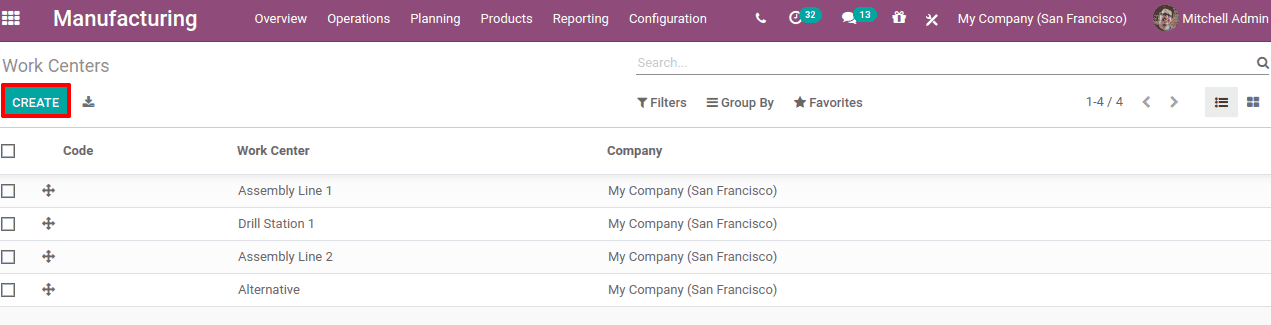

Now go to Configuration > Work centers, one can view all the existing work centers there.

Click on the Create button and create a new work center.

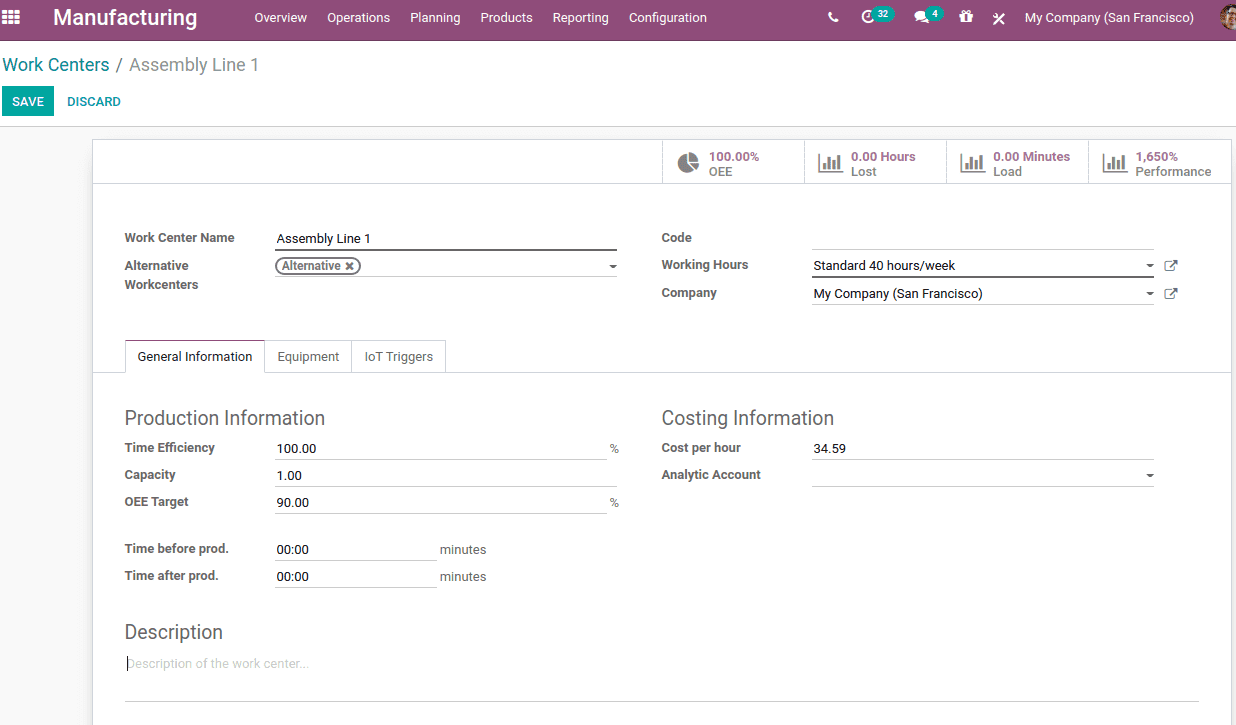

Configure the work center as per requirement. Let us discuss the fields in the work center form:

Work center Name: Name of the work center

Alternative work center: It is a work center used to process the work order of a product if the main work center is busy with another operation

Code: Code for the work center

Working hours: Scheduled working hours of the work center as per the company rules. The user can either choose this from the list or can create and use a new one.

Company: Company to which the work center belongs to can be chosen from the multi-company

Under general information, production information and costing information are set.

Time efficiency: used to define the expected duration of work orders in this work center.

Capacity: Quantity of units which can be manufactured in concurrently

OEE Target: Percentage Over-all Efficiency Target

Time before production: Time to set the pre-production processes such as machine setting

Time after production: Time set for post-production processes like cleaning

Cost per hour: Cost per hour for the work center

Analytic Account: Automate entries in analytic accounting on production orders

The smart buttons in the form will record what is happening in the work center, its performance, and its efficiency.

Alternative Work Center

Manufacturing different products at the same time at the same work center is a challenge in almost all production companies. We have to keep track of which work centers are in production and when it will be free etc. So to avoid the loss of productive time we can set an alternative work center at the beginning of a work center creation.

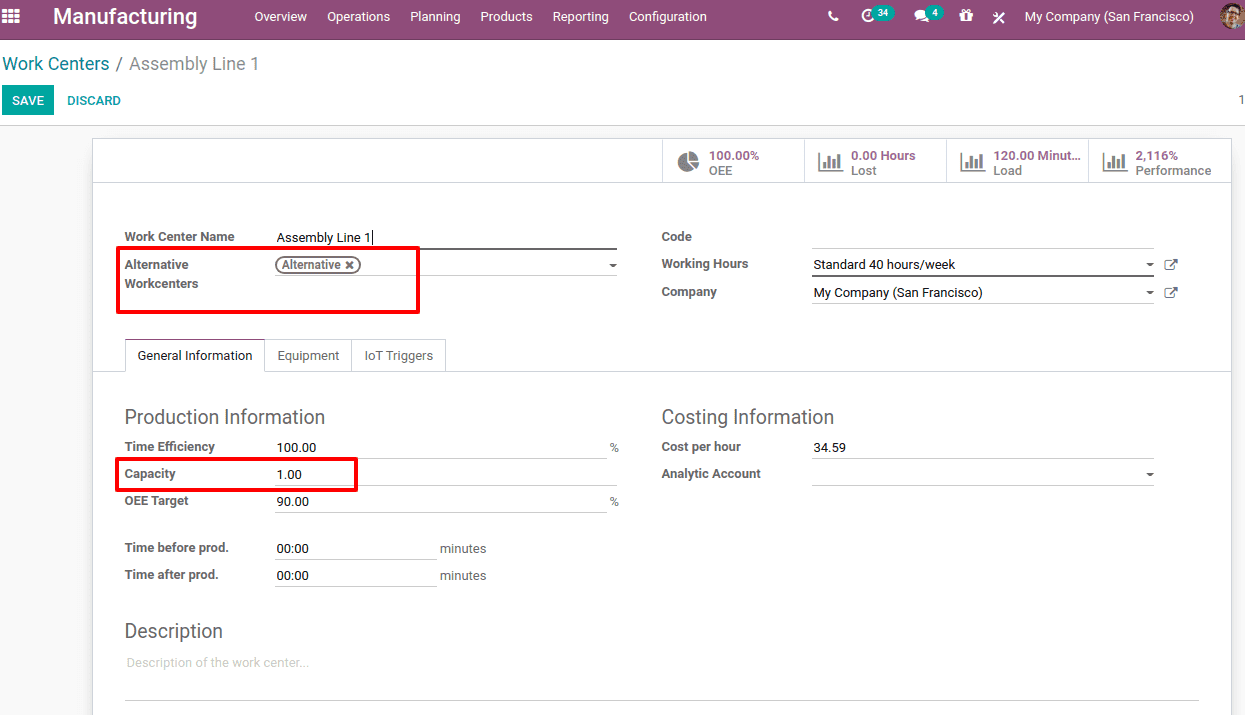

Suppose we have assigned an alternative work center for the work center ‘Assembly 1’.

Capacity specified as one, so at a time this work center can produce only one quantity. Now I have created a manufacturing order for a product ‘table’ having work center ‘Assembly 2’.

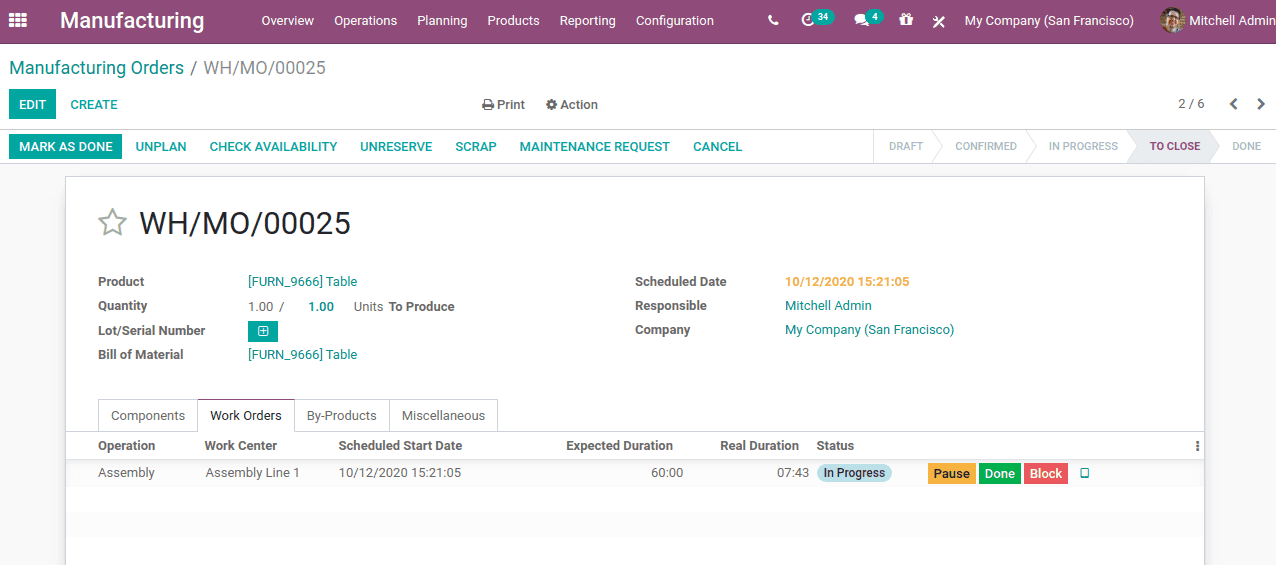

Now this work order is in progress, which means the work center ‘Assembly 1’ is busy with the production. So to make another 1 quantity of the same product we have to create another Manufacturing Order.

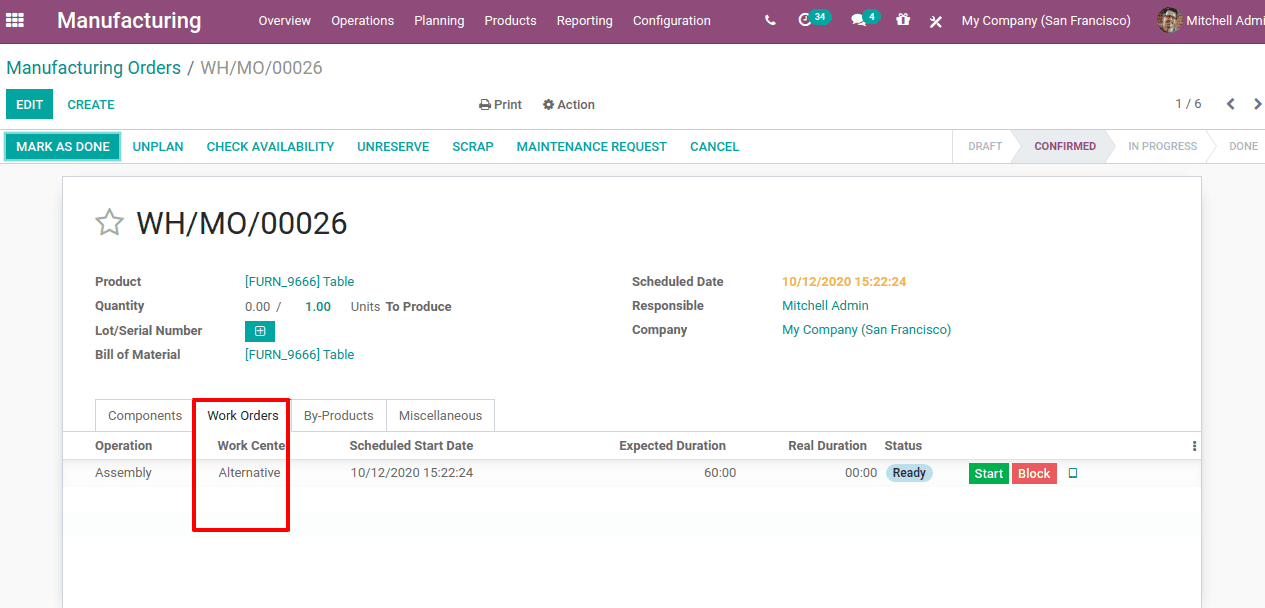

On confirming the second manufacturing order, we can see the work center as ‘Alternative’. This is because ‘Assembly 1’ is busy and the alternative work center for ‘Assembly 1’ is automatically detected for the production of the product. This is how alternative work center work and thereby the manufacturing process makes flexible, cost-effective, and instantly.

Also Read: How to Create Bill of Material (BoM) in Odoo 14